An improved coating molding apparatus

A molding equipment and coating technology, which is applied to the parts, electrical components, bases/shells of connecting devices, etc., can solve problems such as low safety in use, disconnection of plugs, and no locking structure, so as to increase service life and increase safety. The effect of preventing accidental electric shock accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

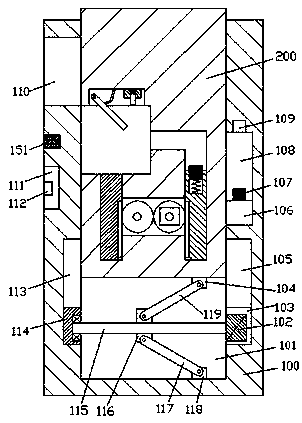

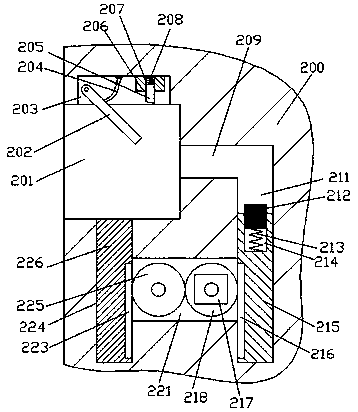

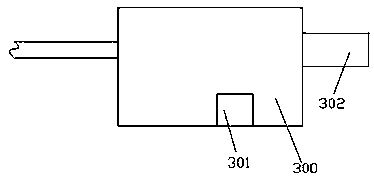

[0016] Combine below Figure 1-3 The present invention will be described in detail.

[0017] refer to Figure 1-3 , an improved paint molding device according to an embodiment of the present invention, comprising a casing 100 and a joint part 300 used in conjunction with the casing 100, a first slide chamber 101 is provided in the top end surface of the casing 100, A sliding frame 200 is installed in the first sliding chamber 101 , and a lifting device is installed in the bottom end of the sliding frame 200 through dynamic cooperation. There is a first insertion cavity 110 that is plugged and connected with the joint part 300, and a second insertion cavity 201 is provided opposite to the first insertion cavity 110 on the left end surface of the slider 200. The inner top wall of the second insertion cavity 201 is provided with a card installation cavity 203, and the opening and closing plate 202 extending into the second insertion and closing cavity 201 is installed in the ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap