Automatic screening device

A technology of automatic screening and execution device, applied in sorting and other directions, can solve problems such as error-prone, small-package product quantity error, etc., to achieve the effect of eliminating human error, high work efficiency, and stable and reliable system

Inactive Publication Date: 2018-12-28

TONGCHENG LIXING ELECTRONICS TECH CO LTD

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the full inspection of packaging equipment after the product is packaged is done manually by personnel. The product is unqualified product, and there are many unqualified products that need to be screened. In the past, employees manually inspected and screened out unqualified products. Products, this kind of manual inspection and selection of unqualified products has become more and more unable to keep up with the progress of the times, the production line is constantly producing, and if the inspection personnel cannot keep up or there are insufficient personnel, the next process will be delayed, and it will not be accurate , Quickly measure its weight, whether the product is overweight or underweight, and it is easier to make mistakes when changing product types frequently

Moreover, most of this process is also completed by manual counting. Due to various objective reasons, manual counting of the number of small packaged products loaded into the finished box often produces errors.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

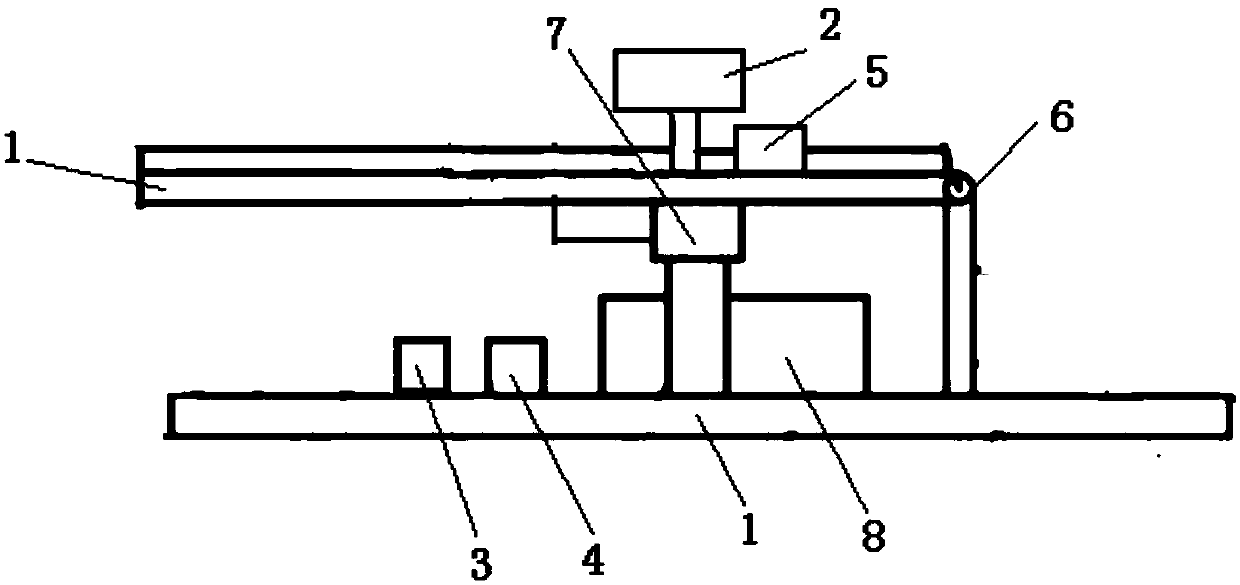

The invention discloses an automatic screening device. The automatic screening device is arranged on an online packaging production line and also comprises a control unit, a weight sensor, a conveyingbelt, a conveying driving device and a screening execution device which are arranged on a support device. The automatic screening device screens unqualified products to a designated unqualified product area, gives alarms and realizes weight monitoring of the automatic production line, and the system is stable, reliable and high in working efficiency.

Description

technical field The invention relates to a device, in particular to an automatic screening device. Background technique At present, the full inspection of packaging equipment after the product is packaged is done manually by personnel. The product is unqualified product, and there are many unqualified products that need to be screened. In the past, employees manually inspected and screened out unqualified products. Products, this kind of manual inspection and selection of unqualified products has become more and more unable to keep up with the progress of the times, the production line is constantly producing, and if the inspection personnel cannot keep up or there are insufficient personnel, the next process will be delayed, and it will not be accurate , Quickly measure its weight, whether the product is overweight or underweight, and it is easier to make mistakes when changing product types frequently. And this operation is mostly also finished by manual counting, and due...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B07C5/18B07C5/36

CPCB07C5/18B07C5/362

Inventor 杨昆

Owner TONGCHENG LIXING ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com