Automatic online weighing and screening equipment for manufactured meat packaging products

A technology for screening equipment and meat products, which is applied in the direction of automatic packaging control, packaging food, packaging item types, etc. It can solve the problems of small packaging product quantity error, error-prone, increased production cost and product quantity, etc., to achieve system stability and reliability. The effect of human error, easy cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

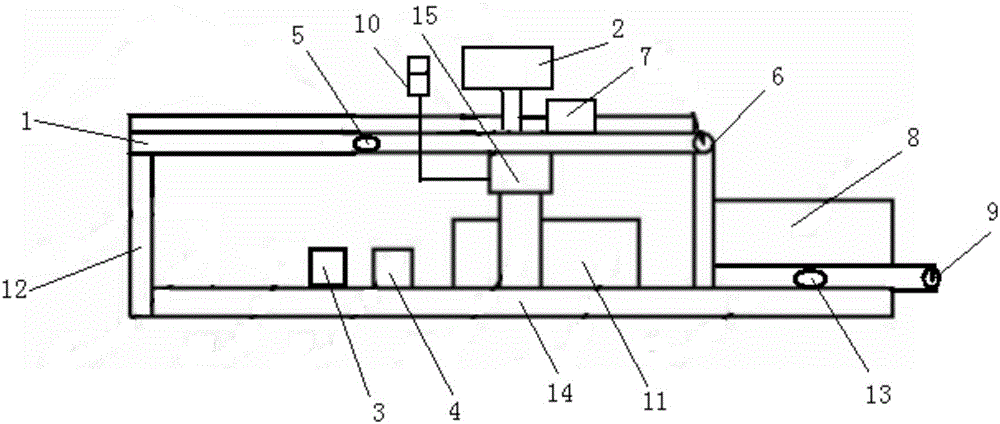

[0019] See figure 1 , the present invention is an automatic online weighing and screening equipment for meat packaging products, including a support device, the support device is used for support, the support device includes a base 14 and a bracket 12 vertically fixed on the base 14, the device of the present invention It is arranged on the meat products online packaging production line, and also includes an automatic controller 2, a weight sensor 15, a carrier belt 1, a carrier drive device and a screening execution device arranged on the support device, and the weight sensor 15 and the screening execution device are respectively connected to The automatic controller 2, the weight sensor 2 is used to detect the weight of the meat product packaging and generate a weight signal, the automatic controller 2 is used to set the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com