System and method for measuring feed conversion ratio of cage breeding poultry

A technology for measuring system and feed-to-meat ratio, which is applied in the field of poultry and livestock breeding, can solve the problems of increasing labor intensity, making it difficult to ensure that other poultry can eat, increasing randomness, etc., so as to save labor costs and material costs, obtain accuracy and can The effect of convenient control and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

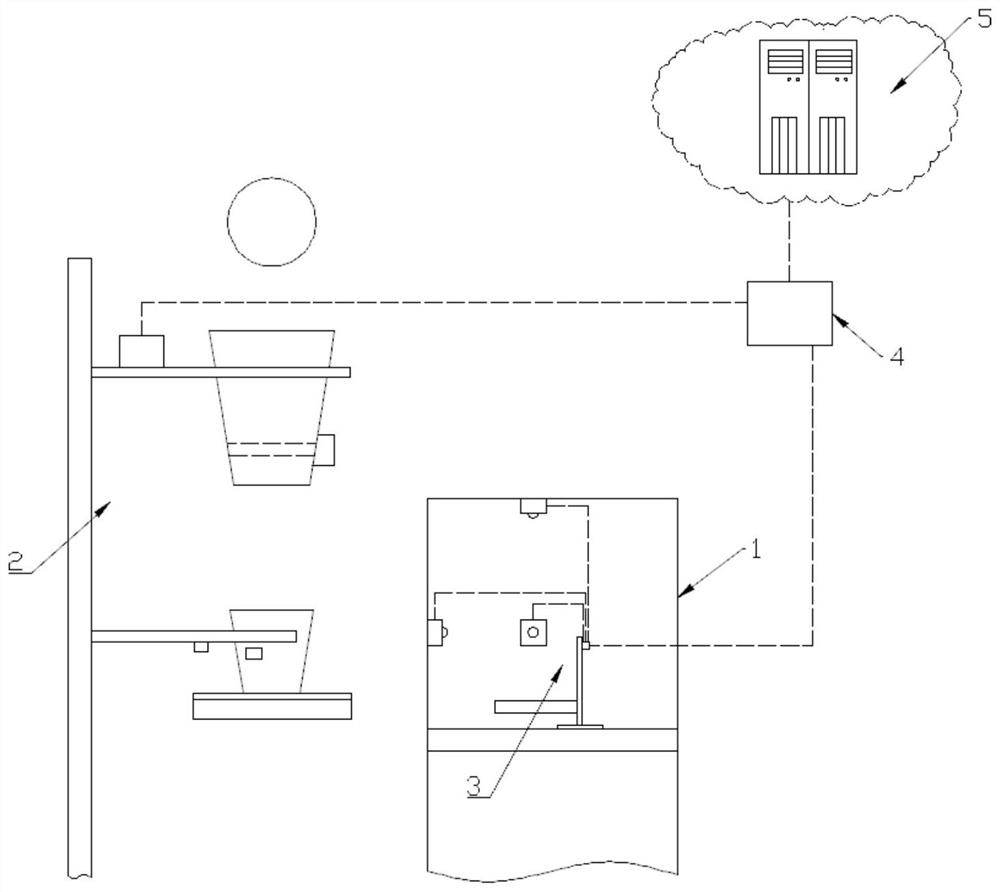

[0039] Such as figure 1 As shown, the present embodiment provides a system for measuring the feed-to-meat ratio of caged breeding poultry, comprising: a poultry breeding cage 1; a quantitative feeding system 2 arranged on the outside of the poultry breeding cage 1; 1 internal individual weight monitoring system 3; the data repeater 4 connected to the quantitative feeding system 2 and the individual weight monitoring system 3 signals respectively; the server 5 arranged in the cloud and connected to the data repeater 4 signal .

[0040] Wherein, the poultry breeding cage 1 is a commonly used cage in the field of conventional poultry breeding, which can be combined together to form a poultry raising frame or a centralized feeding system. The present invention is not limited by the number of poultry cages 1 . The quantitative feeding system 2 refers to a feeding system that can accurately control the feeding amount of feed as required. There are many ways to realize it in the pr...

Embodiment 2

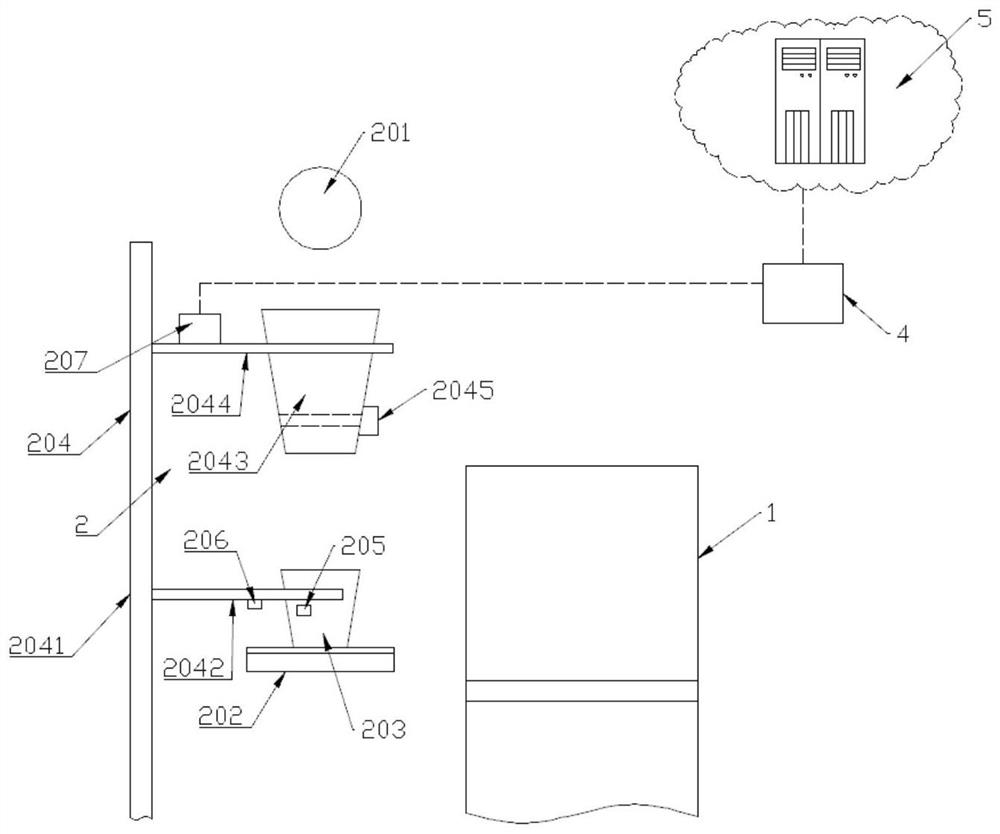

[0044] This embodiment is developed on the basis of above-mentioned embodiment 1, as figure 2 As shown, the present embodiment provides a better quantitative feeding system 2.

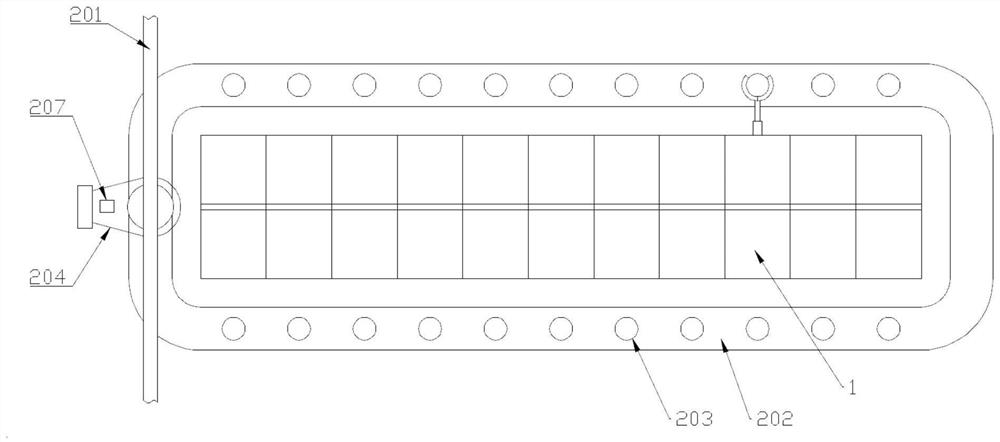

[0045] The quantitative feeding system 2 includes: a main material line 201, a circular feeding platform 202, an individual feeding bucket 203 and an individual feeding bucket feeding rack 204;

[0046] The circulating feeding platform 202 is arranged below the main material line 201, and there is an overlapping portion with the main material line 201 on the plane; the individual feeding bucket 203 is arranged on the upper surface of the circulating feeding platform 202, and is connected The individual poultry in the poultry breeding cage 1 has a one-to-one correspondence; the individual feeding bucket feeding rack 204 is arranged on one side of the circulating feeding platform 202, and is close to the overlap between the circulating feeding platform 202 and the main material line 201. department;

...

Embodiment 3

[0054] Such as figure 2 As shown, this embodiment is developed on the basis of the above-mentioned embodiment 2. This embodiment provides a specific structure of the feeding rack 204 for individual feeding buckets.

[0055] The individual feeding bucket feeding frame 204 includes: main support 2041, feeding bucket operating arm 2042, main feeding bucket 2043 and main feeding bucket operating arm 2044;

[0056] The main bracket 2041 is fixedly arranged on one side of the circulating feeding platform 202;

[0057] The feeding barrel operating arm 2042 is arranged at the lower part of the main bracket 2041, and its setting position is higher than the circulation feeding platform 202 in the vertical direction, and points to the overlapping part of the circulation feeding platform 202 and the main material line 201; It should be understood that the feeding barrel operating arm 2042 in this embodiment is located between the circulating feeding platform 202 and the main material l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com