A device and method for measuring the gas content inside a die casting

A technology of die casting and gas content, applied in the direction of analyzing materials, instruments, etc., can solve problems such as measurement error, and achieve the effect of solving the problem of measurement error, conducive to design and optimization, high measurement accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

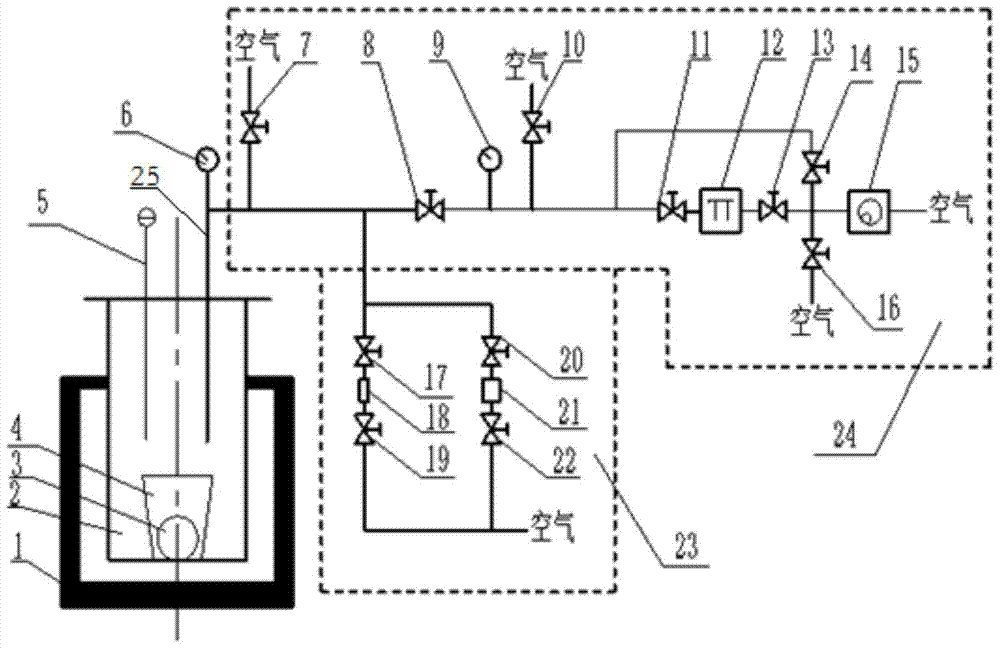

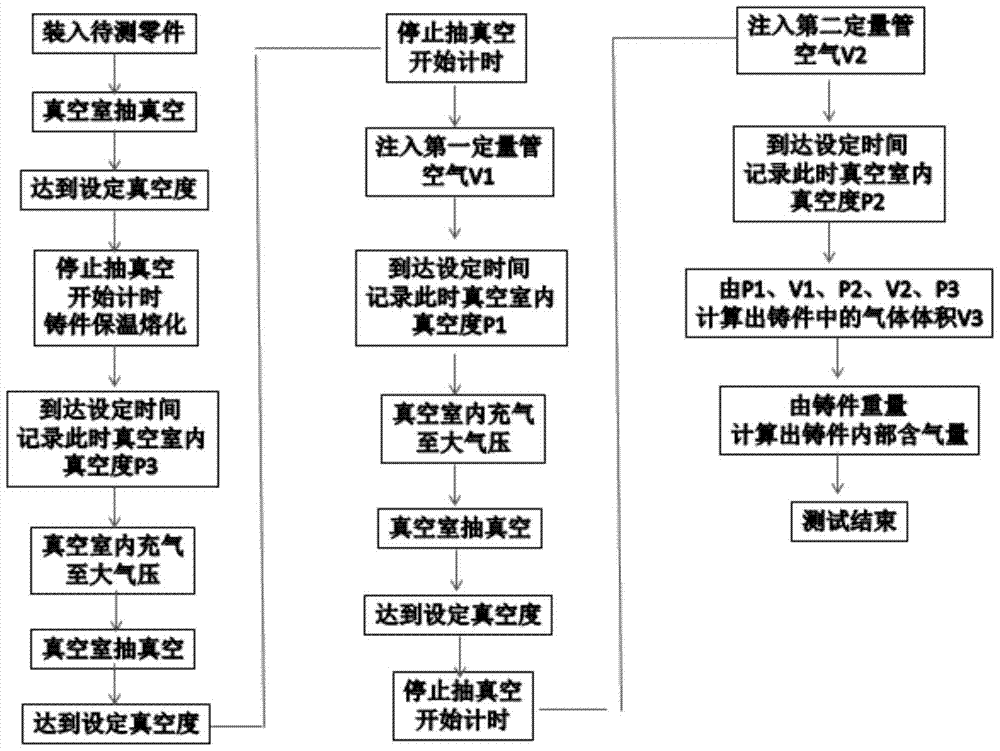

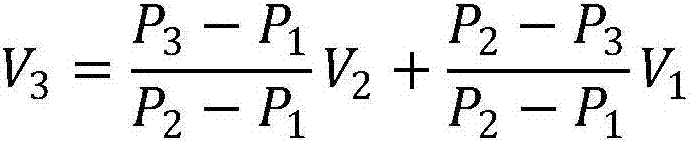

Method used

Image

Examples

Embodiment 1

[0096] The AlSi10Mg alloy was subjected to ordinary die-casting and vacuum die-casting on a 2800KN horizontal cold chamber die-casting machine, and this device was used to test the gas content of the obtained parts. The comparative test results are shown in Table 1.

[0097] Table 1 AlSi10Mg alloy common die-casting and vacuum die-casting parts gas content (ml / 100g)

[0098]

[0099] It can be seen from Table 1 that the gas content in vacuum die castings is significantly smaller than that of non-vacuum ordinary die castings, which quantitatively verifies that the internal quality of vacuum die castings is better than that of ordinary die castings, providing a reference for process optimization.

Embodiment 2

[0101] Cut each part of the vacuum die casting, and test the air content of the parts, cake and overflow tank respectively. The test results are shown in Table 2.

[0102] Table 2 Air content of each part of the die casting (ml / 100g)

[0103]

[0104] It can be seen from Table 2 that even if vacuum die casting is used, the air content in different parts of the die casting is also different. At the same time, it proves that the air content of the die casting body is smaller than that of the cake, and the air content of the cake part is smaller than that of the overflow tank. . This provides a strong reference for the development and evaluation of structural components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com