Spliced wood door frame

An assembled, door frame technology, applied in the direction of window/door frame, window/door, building components, etc., can solve the problems of no buffering of the door leaf, poor portability of the installer, and damage, etc., and achieve the effect of being easy to carry and install.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

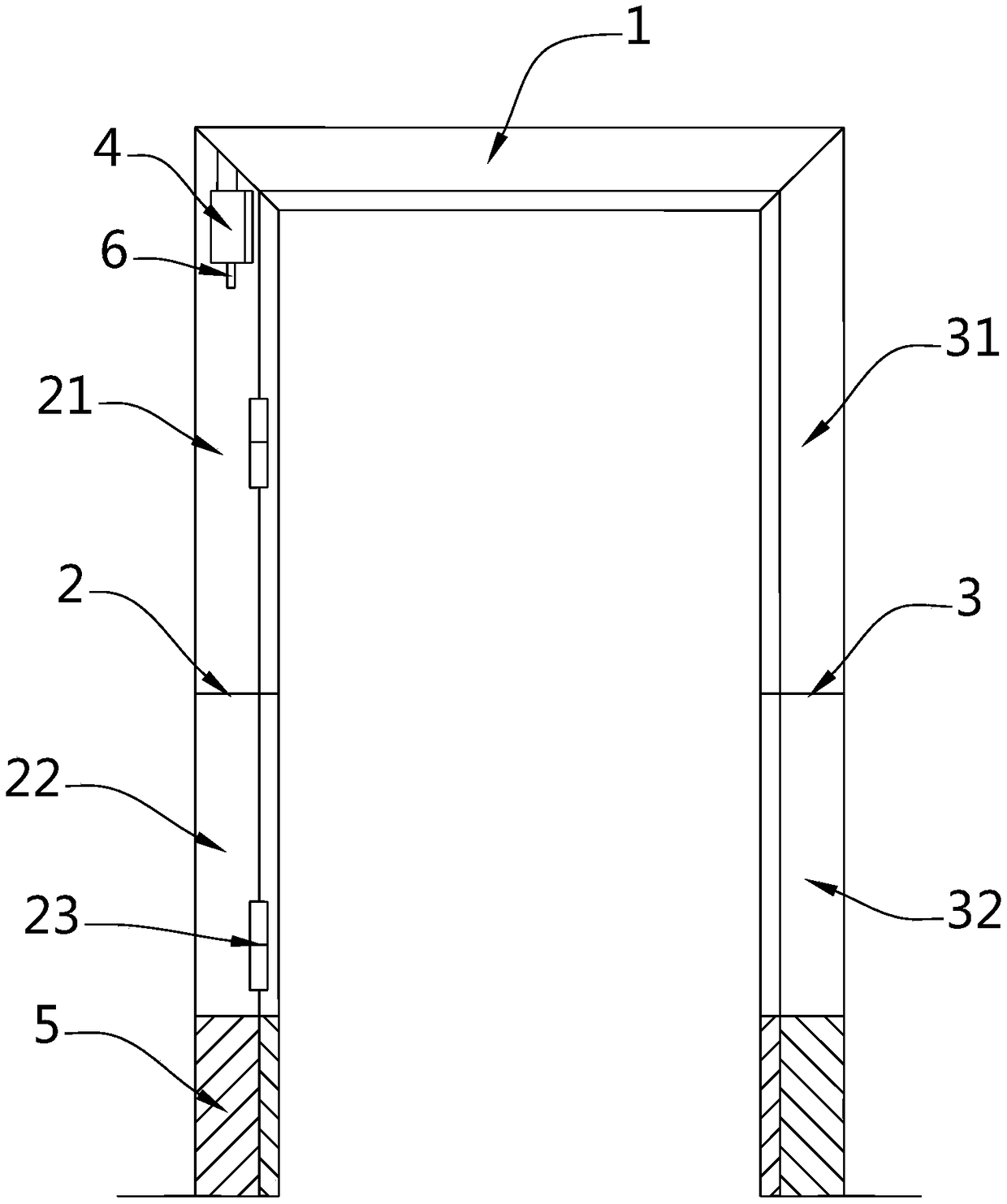

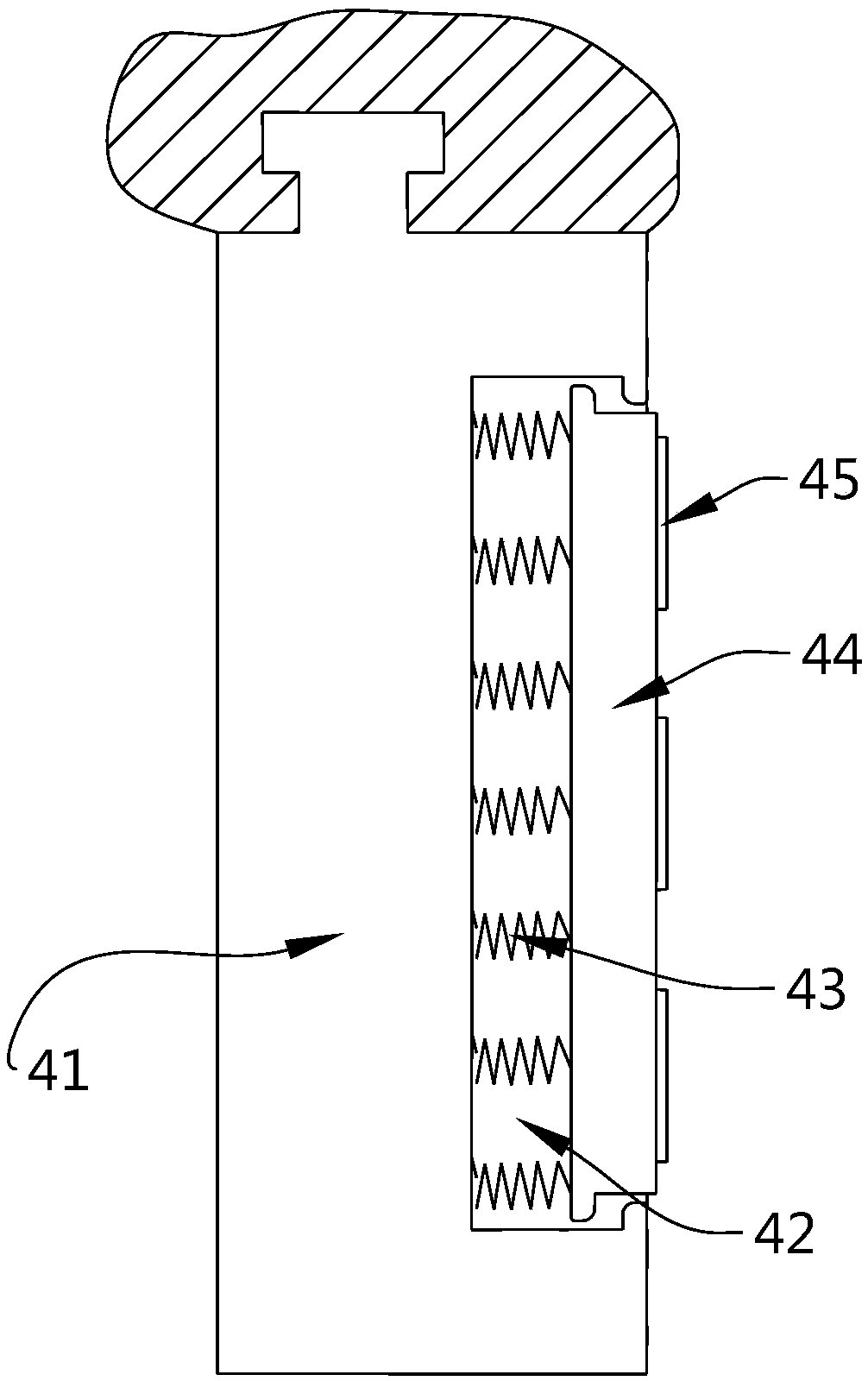

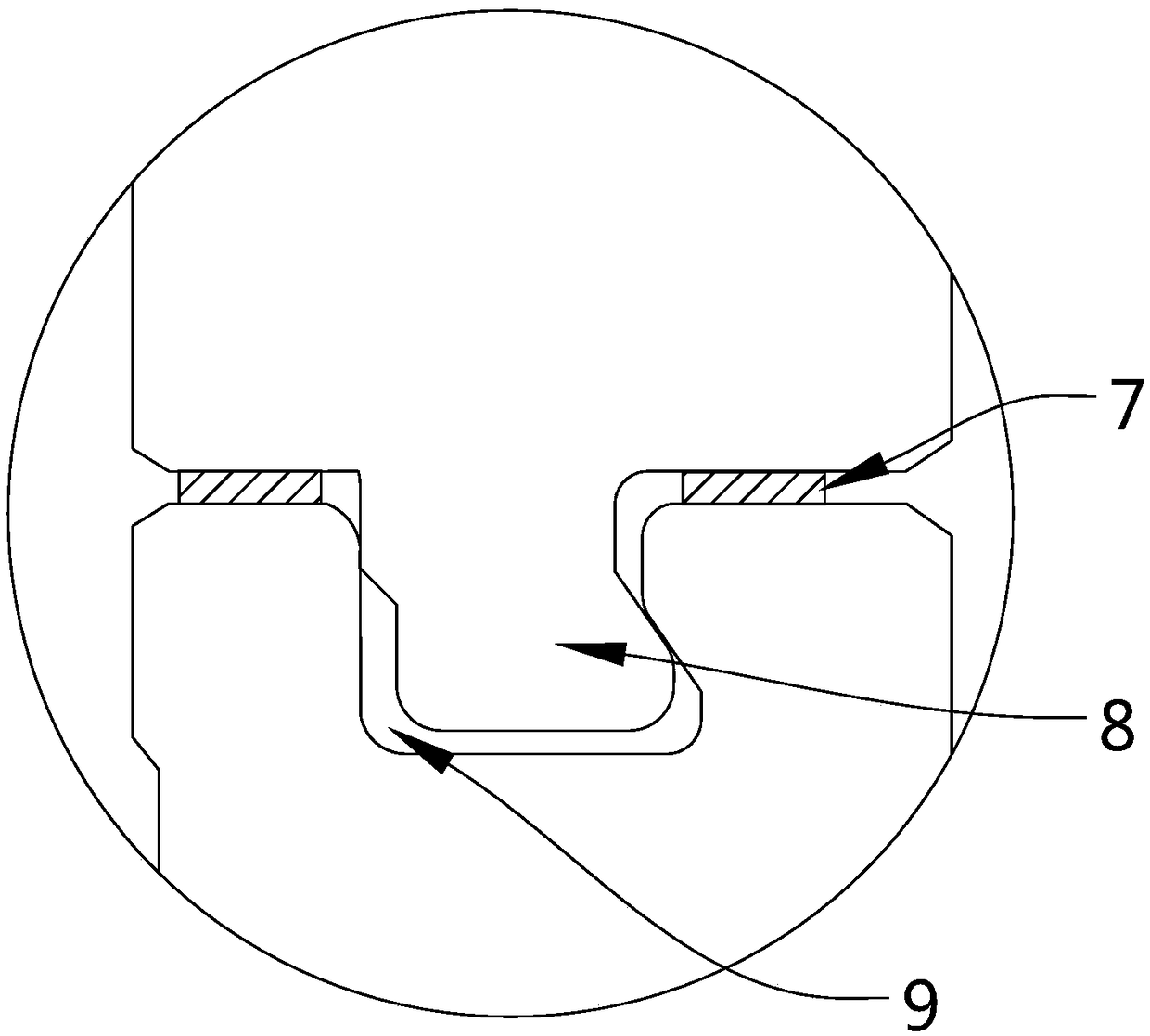

[0017] Embodiment: Assembled wooden door frame, structure such as Figure 1 to Figure 3 As shown, it includes an upper door frame 1, a first side door frame 2 and a second side door frame 3 that form a rectangular structure together with the ground, and the first side door frame 2 includes a first sub-side door frame 21 and a second sub-side door frame 22 that are mortised together , the second side door frame 3 includes a third sub-side door frame 31 and a fourth sub-side door frame 32 that are mortised and mortised, and hinges 23 are provided on the first sub-side door frame 21 and the second sub-side door frame 22, and the first sub-side door frame The upper part of the door frame 21 is mortised with a buffer strip 4 vertical to the first sub-side door frame 21; A wooden sliding bar 44 is connected, and the outer surface of the wooden sliding bar 44 is provided with a magnetic strip 45 .

[0018] The bottoms of the second sub-side door frame 22 and the fourth sub-side door...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com