A structural fault detection method and system for measuring relative deformation of wind turbine blades

A technology of relative deformation of wind turbine blades, which is applied in the direction of measuring devices, instruments, and optical devices, and can solve problems such as failure and measurement of difficult-to-rotate blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

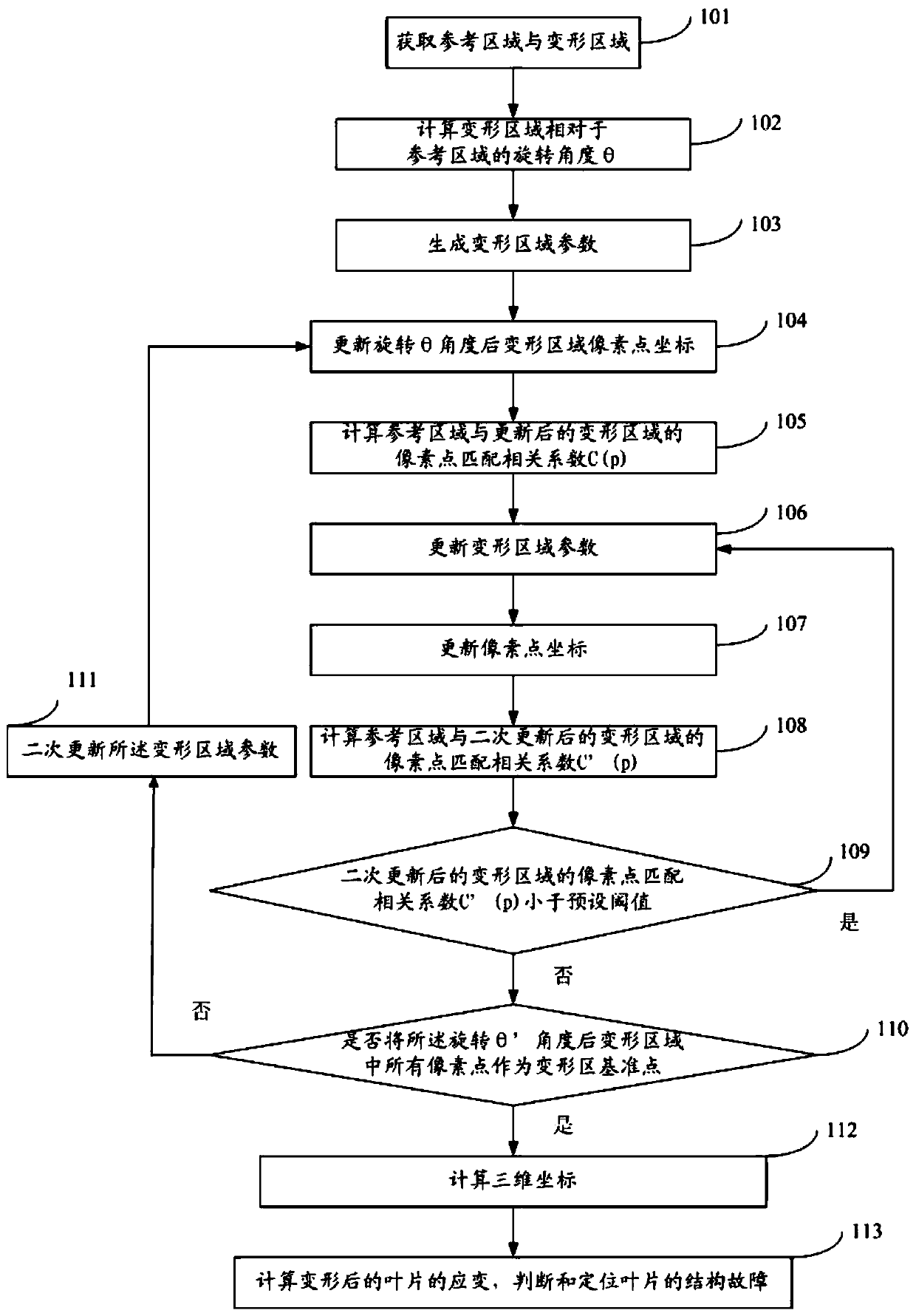

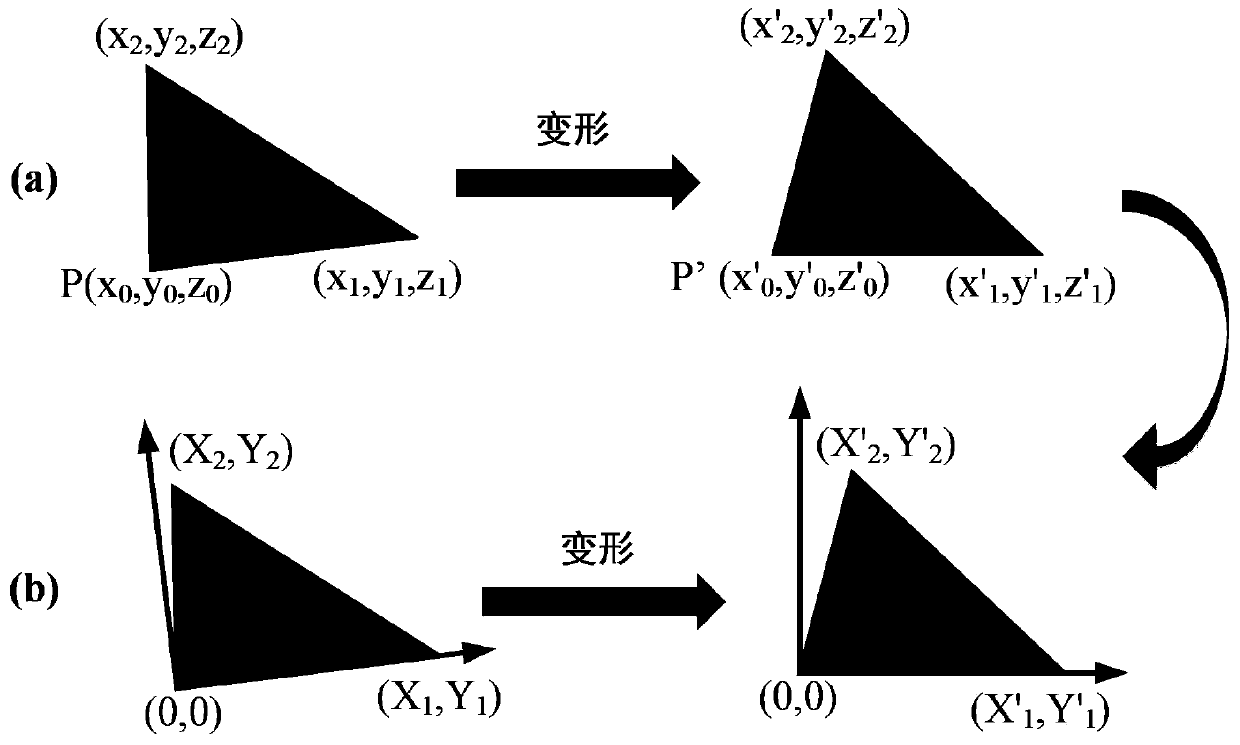

[0080] figure 1 It is a flowchart of a structural fault detection method based on measuring the relative deformation of wind turbine blades in an embodiment of the present invention, such as figure 1 As shown, the structural fault detection method for measuring the relative deformation of wind turbine blades provided by the present invention includes:

[0081] Step 101: Obtain a reference area and a deformation area.

[0082] The reference area is an area selected on the blade surface image before deformation, and the reference area includes several feature points of the reference area; The transformation algorithm obtains a deformed area matching the reference area, and the deformed area includes several deformed area feature points corresponding to the reference area feature points; the number of horizontal pixels of the reference area and the deformed area The number of pixels is the same.

[0083] Step 102: Calculate the rotation angle θ of the deformed area relative to...

Embodiment 2

[0165] Figure 4 It is a structural diagram of a structural fault detection system for measuring the relative deformation of wind turbine blades in an embodiment of the present invention, as Figure 4 As shown, the structural fault detection system for measuring the relative deformation of wind turbine blades provided by the present invention includes:

[0166] A reference area and deformation area acquisition module 201, configured to acquire a reference area and a deformation area; the reference area is an area selected on the blade surface image before deformation, and the reference area includes several reference area feature points; the The deformed area is to perform feature point matching on the deformed blade surface image to obtain a deformed area matched with the reference area, and the deformed area includes several deformed area feature points corresponding to the reference area feature points; the reference The number of horizontal pixels and the number of vertic...

Embodiment 3

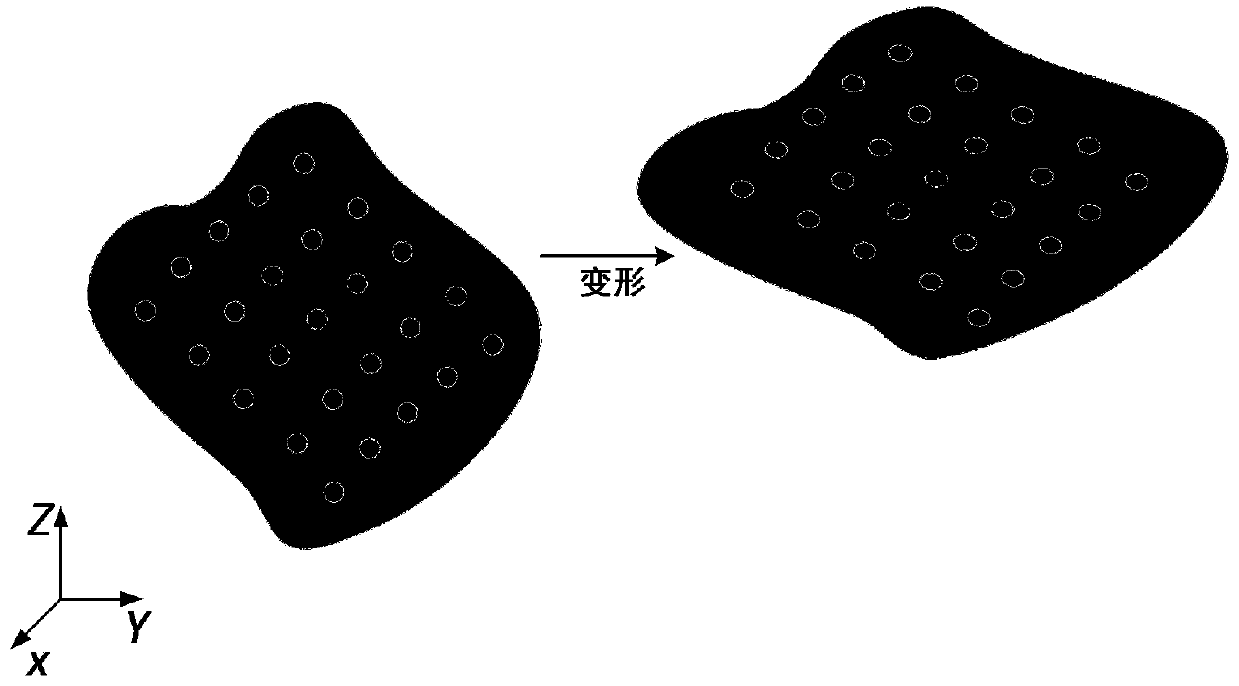

[0180] The invention is used to measure the deformation of a fan blade containing a crack defect, and diagnose the crack position. According to the measurement method provided by the invention, the measurement process is:

[0181] To measure an iron fan blade, saw a crack with a depth of about 0.5mm on the back of the blade to simulate the crack defect of the blade. Spray black and white speckle particles on its surface before the experiment, fix the fan shaft on the experimental platform after installation, fix the dual camera system on the front of the blade, adjust the position of the camera to ensure clear imaging of the blade during rotation, and calibrate it The internal and external parameters of the system.

[0182] Take the leaf in its horizontal position as a reference position and take its image. Then rotate the blade counterclockwise about 20° as the target position, and use the screw micrometer to load the front of the blade tip at the target position to 10mm, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com