Building material crushing mixing and feeding device

A technology for buildings and silos, which is applied in the field of feeding machines, can solve the problems of unavoidable smoke and dust, increase the completion time of construction projects, and inconvenient use of building materials, so as to facilitate the closed crushing work, shorten the completion time, and avoid gas leakage. The effect of venting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

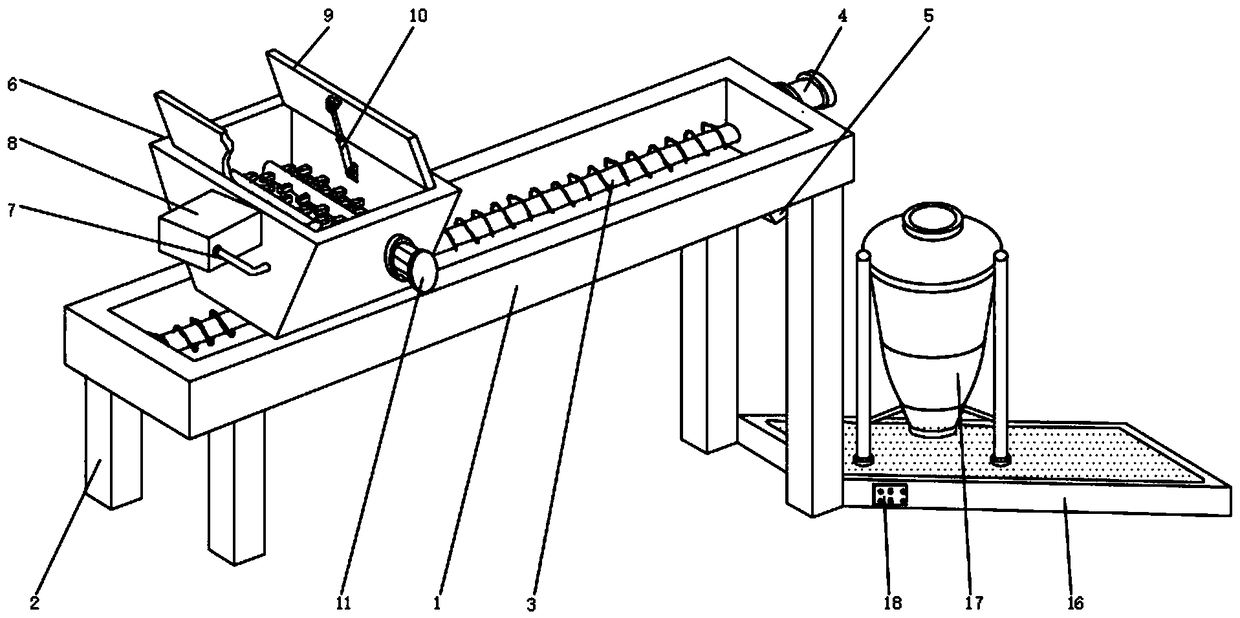

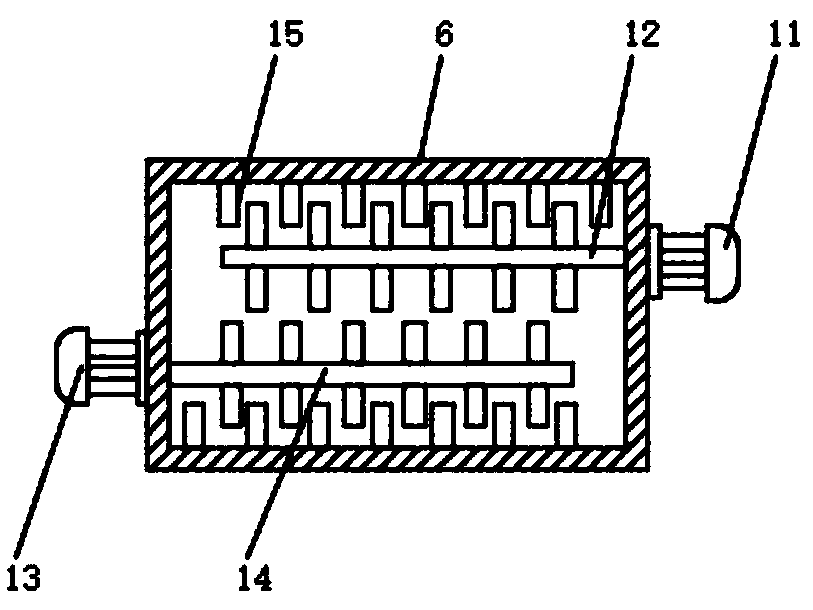

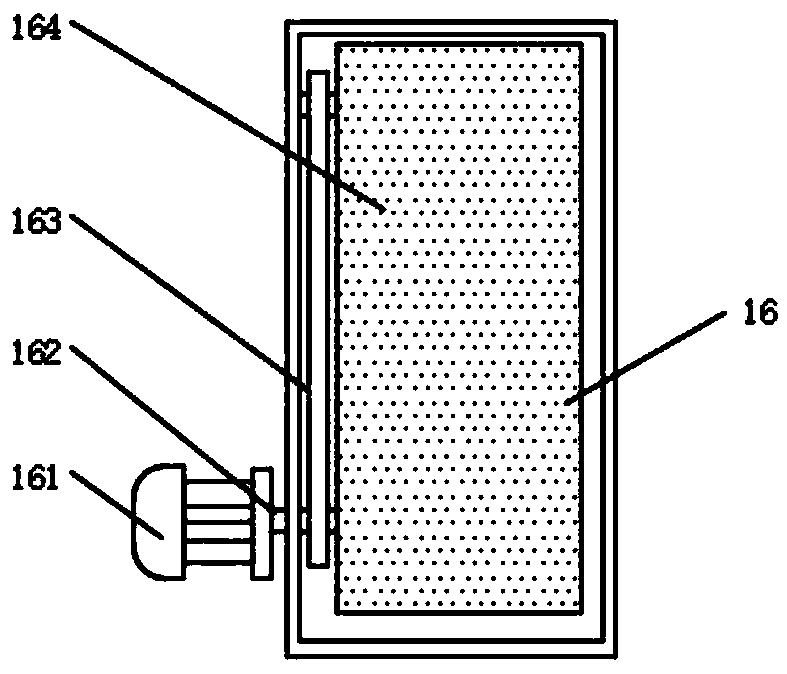

[0022] see Figure 1~4 , in an embodiment of the present invention, a building material crushing and mixing feeding device includes a feeding channel 1, a stepping motor 4 is fixedly installed on the side surface of the feeding channel 1, and a helical twister is installed on the inner rotation of the feeding channel 1 Dragon 3, the bottom end of the feeding channel 1 is fixedly installed with a support column 2, and the bottom end of the material delivery channel 1 is provided with a discharge port 5 near the rear side of the supporting column 2, and the inside of the feeding channel 1 corresponds to the spiral twisting The upper end of the dragon 3 is connected with a crushing upper material bin 6, and the upper end of the crushing upper material bin 6 is rotatably connected with a cover plate 9, and a first motor 11 is fixedly installed on the front surface of the crushing upper material bin 6, and the crushing upper material bin 6 A first crushing tooth 12 is installed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com