Trimming punching die

A technology of trimming punching dies and punches, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of easily damaged molds, failure to improve efficiency, increase costs, etc., and achieve the effect of quick replacement of punches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

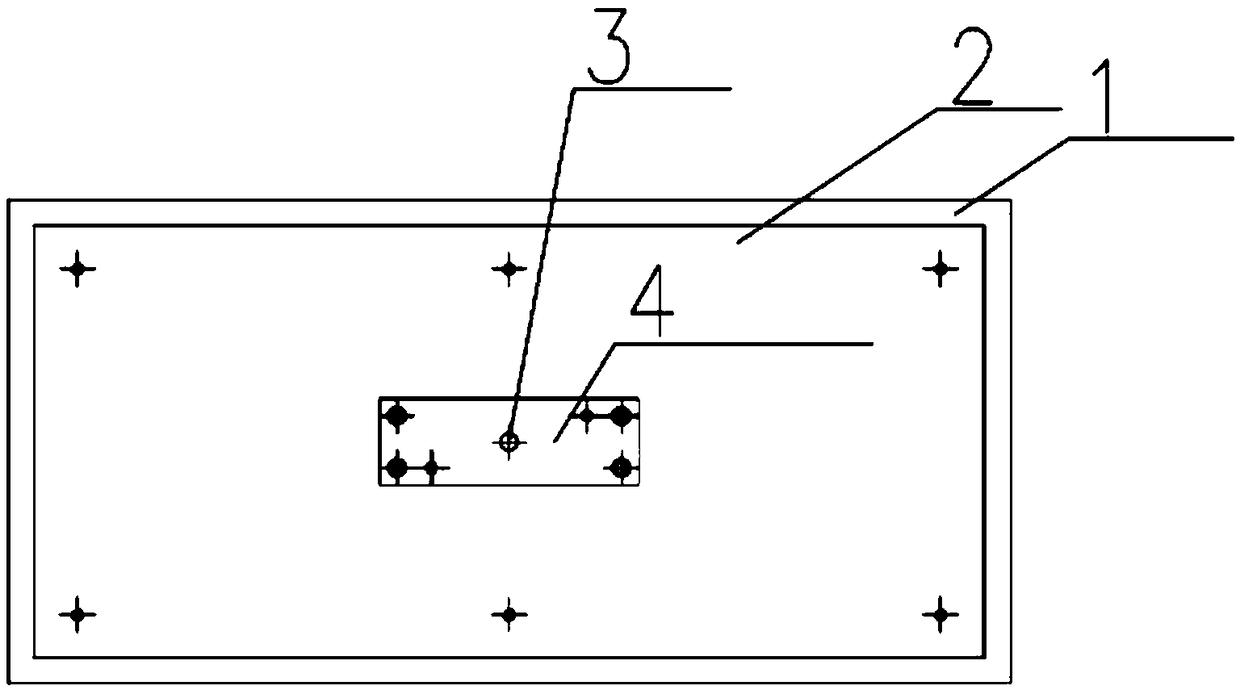

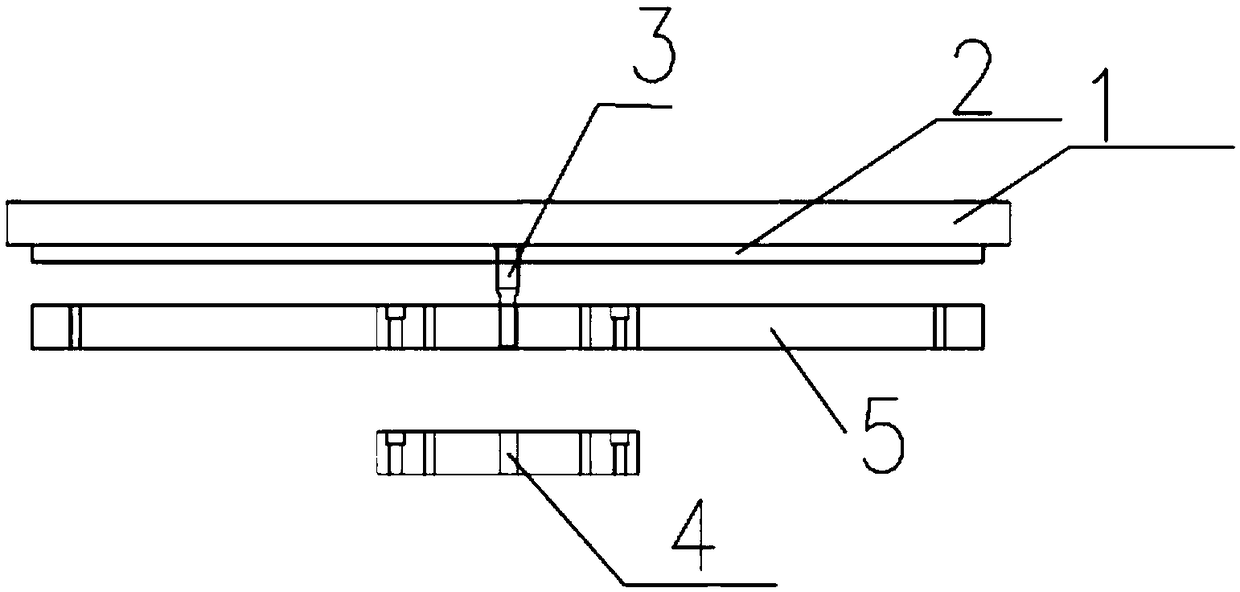

[0010] Referring to the accompanying drawings, it can be seen that the rapid replacement punch trimming punching die for auto parts of the present invention is characterized in that it includes a template 1, a fixed plate 2 fixed on the template 1, and a large binder plate 5 is fixed on the fixed plate 2 , the small binder plate 4 is located in the middle of the large binder plate 5, and the punch 3 passes through the small binder plate 4 and the large binder plate 5 and is fixed on the fixed plate 2.

[0011] In the present invention, the small binder plate and the large binder plate are made into detachable structures, and damaged or damaged punches can ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap