Manipulator trajectory planning method based on sorting process

A technology of manipulators and crafts, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve complex problems and achieve the effects of simplicity, improvement of vibration, and reduction of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Parallel manipulators are widely used in food, medical, chemical and other fields, and require high speed and high precision. A typical application for parallel robots is sorting operations, ie pick and place actions. With the great improvement of production efficiency, the demand for pick-and-place action speed is getting stronger and stronger. In the high-speed action state, a series of problems will occur, such as the parallel manipulator's pick-and-place accuracy is greatly reduced, the vibration is severe, and the component parts are worn out. Increase, etc., eventually lead to a significant reduction in the service life of the parallel manipulator, increasing the extra cost of the enterprise.

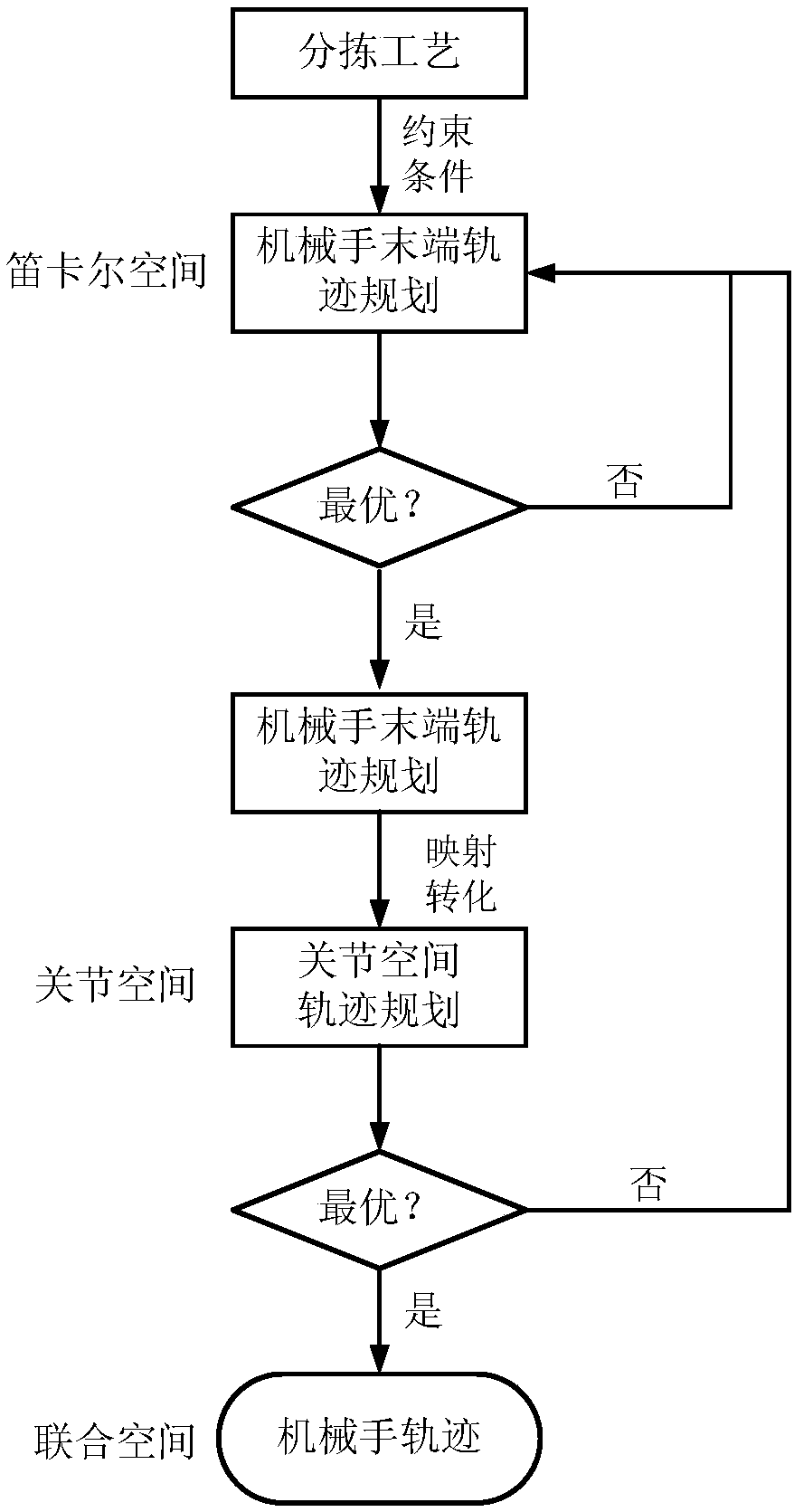

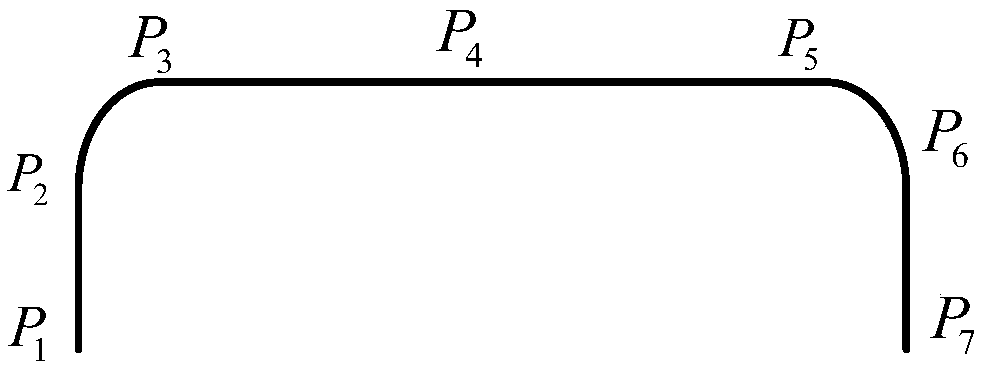

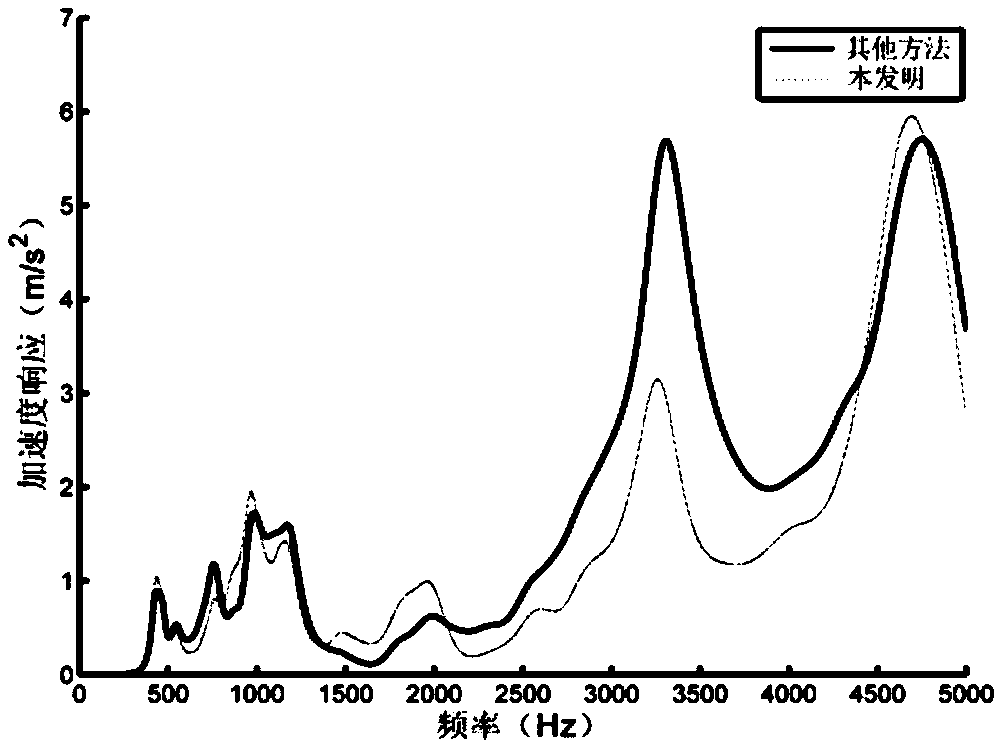

[0025] Aiming at the characteristics of the parallel manipulator sorting process, aiming at improving the motion stability of the parallel manipulator and reducing the impact of the motion process, this technical solution proposes a joint trajectory planning method based on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com