Water electrolyzing machine with functions of automatic internal cleaning and automatic aged water drainage and working method thereof

A technology for automatic discharge and electrolysis of water, which is applied in chemical instruments and methods, water/sewage treatment, water/sewage treatment equipment, etc., and can solve problems such as fouling of electrolyzers and pipelines of electrolyzed water machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

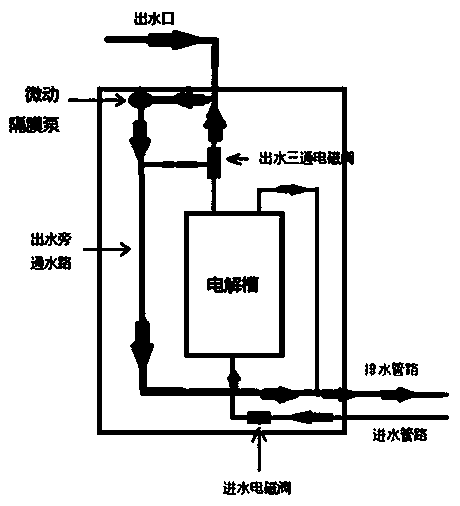

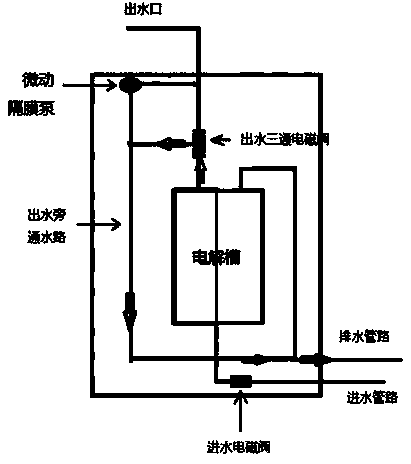

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0017] The present invention provides an electrolyzed water machine with automatic internal cleaning and automatic discharge of old water and its working method. Using the electrolyzed water machine firstly solves the problem of fouling of the electrolyzer and pipelines that has plagued the performance of the electrolyzed water machine for a long time. The second is to ensure that the user does not use the water machine for a long time, and can drink fresh weak alkaline water when using it again. Odor and stale issues are avoided.

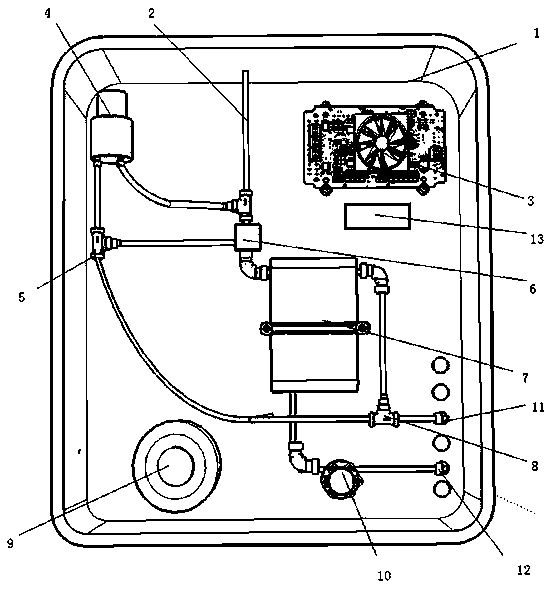

[0018] As an embodiment of the electrolyzed water machine of the present invention, the present invention provides such as figure 1 Shown is an electrolyzed water machine with automatic internal cleaning and automatic discharge of old water, including a housing 1, an alkaline water outlet 2, a main control board 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com