Hot runner injection mold for door check

A hot runner injection molding and door limiting technology, which is applied in the field of automobile production, can solve the problems of blockage of injection holes, affecting product performance, and large injection resistance, and achieves the effects of speeding up cooling and shaping, improving product quality, and facilitating installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

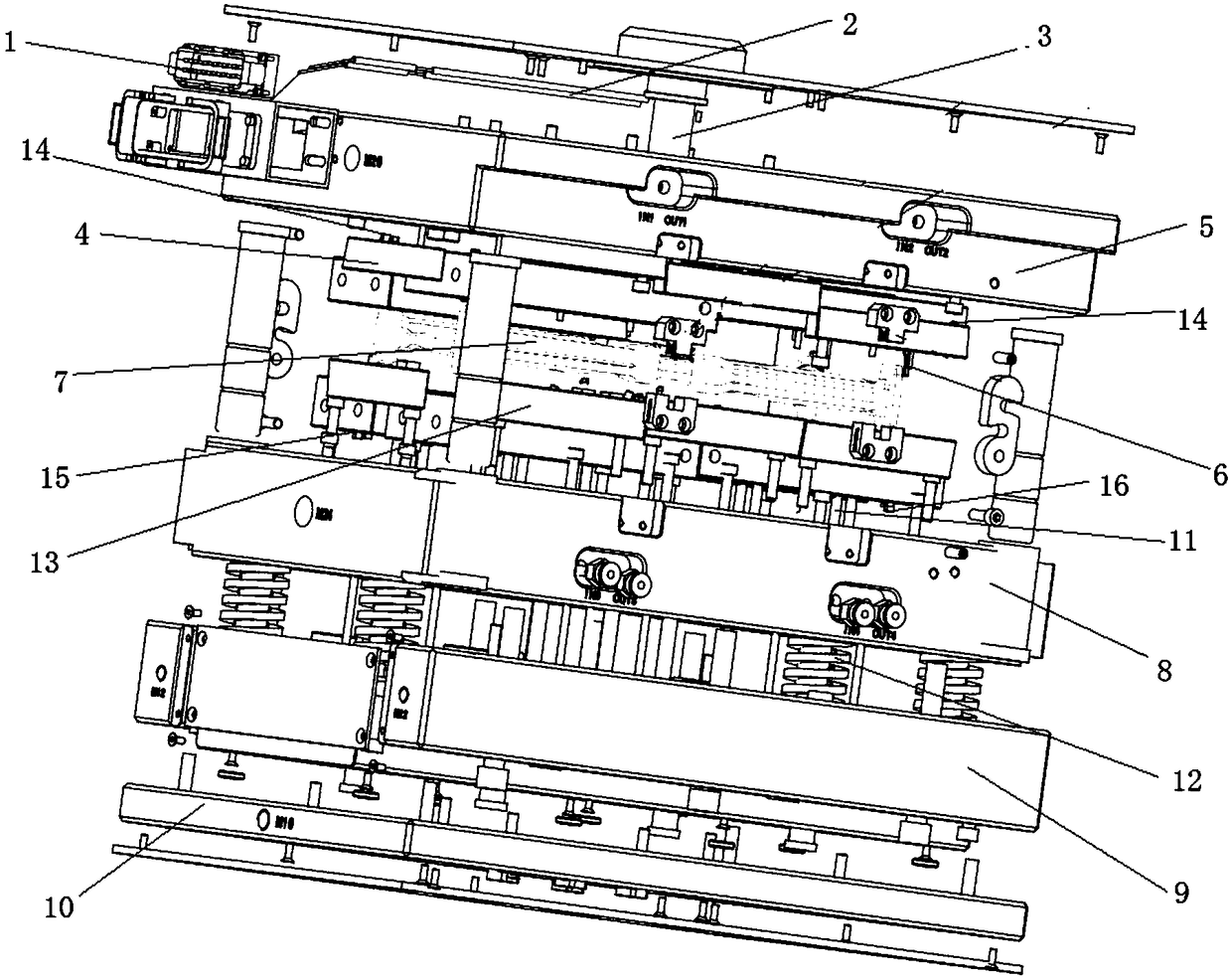

[0020] A hot runner injection mold for a door limit arm, its structure is as follows figure 1 As shown, it includes a fixed mold and a movable mold. The fixed mold is provided with a fixed template 5 and a front mold core 4 fixedly arranged on the fixed template 5. The movable mold is provided with a movable mold seat plate 10, a mold foot 9, and a movable template. 8 and the rear mold core 13 arranged on the movable platen 8, the front mold core 4 and the rear mold core 13 form a cavity, the fixed mold includes a raw material interface 1 and a hot runner 2, and the outer wall of the hot runner 2 is provided with a heating unit , The front mold core 4 is provided with a feed port 3 and an air outlet 14, the feed port 3 is connected to the hot runner 2, and the movable die is provided with an ejection unit for demoulding. The feed inlet 3 is located at the middle part of the front die core 4, and the air outlet 14 is positioned at the upper surface of the front die core 4 both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com