Environmental protection organic tableware wet pressing forming servo pump control system

An organic and tableware technology, applied in servo motors, servo meter circuits, servo motor components, etc., can solve problems such as oil leakage, complicated connection of full hydraulic drive pipelines, environmental pollution, etc.

Active Publication Date: 2022-05-31

江苏扬力液压装备有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] It is more complicated to use full oil pressure to drive the pipeline connection, and there are many joints that may easily cause oil leakage points. Under the condition of oil pressure impact and long-term use of seal aging, oil leakage is easy to occur, and the maintenance workload is relatively large.

[0005] It usually takes 15-30 seconds for the machine tool to hold the pressure in the wet-press forming process of environmentally friendly organic tableware. During this period, if the motor is always running, there will be a lot of energy waste

Match the hydraulic pump station according to the operating speed of the machine tool, usually the required oil volume is 7-10 times the displacement of the oil pump, and there is waste in the use of oil

Under normal use, the oil needs to be filtered and replaced every year, which pollutes the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

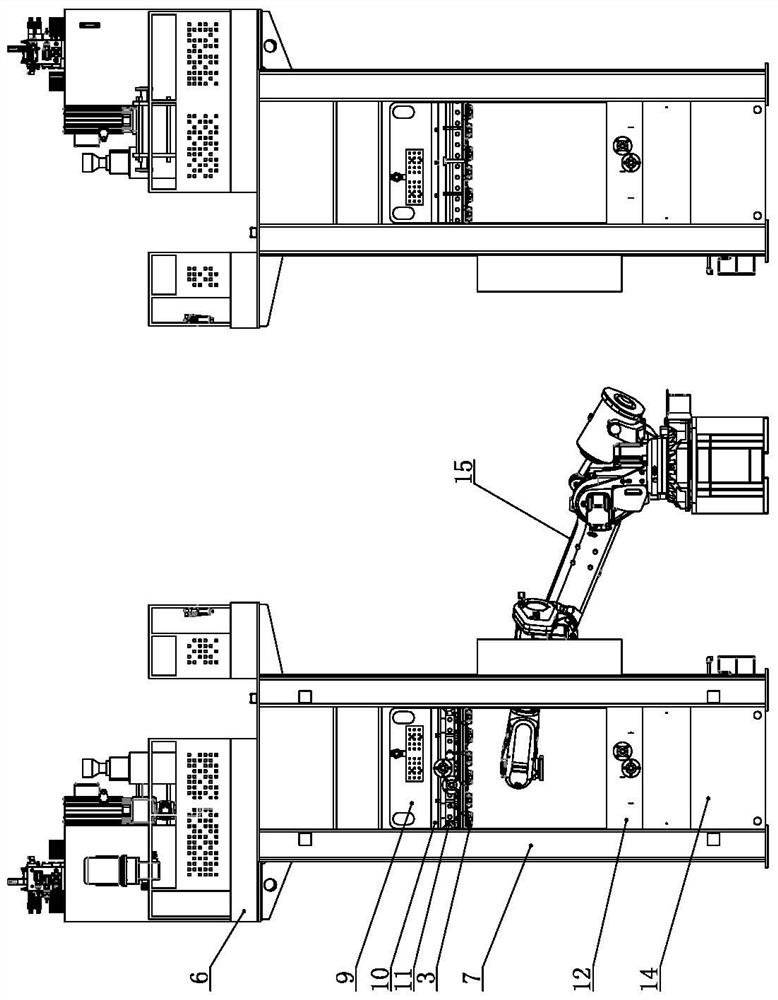

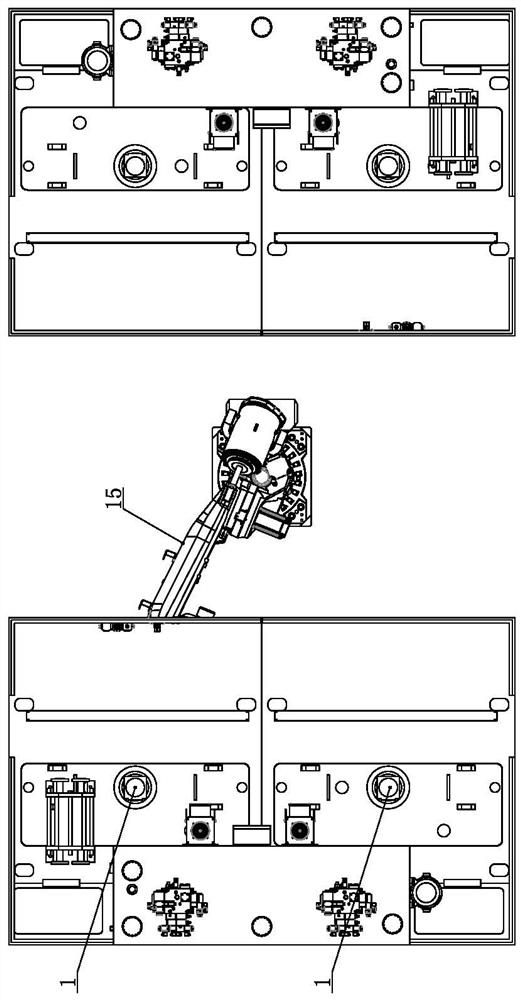

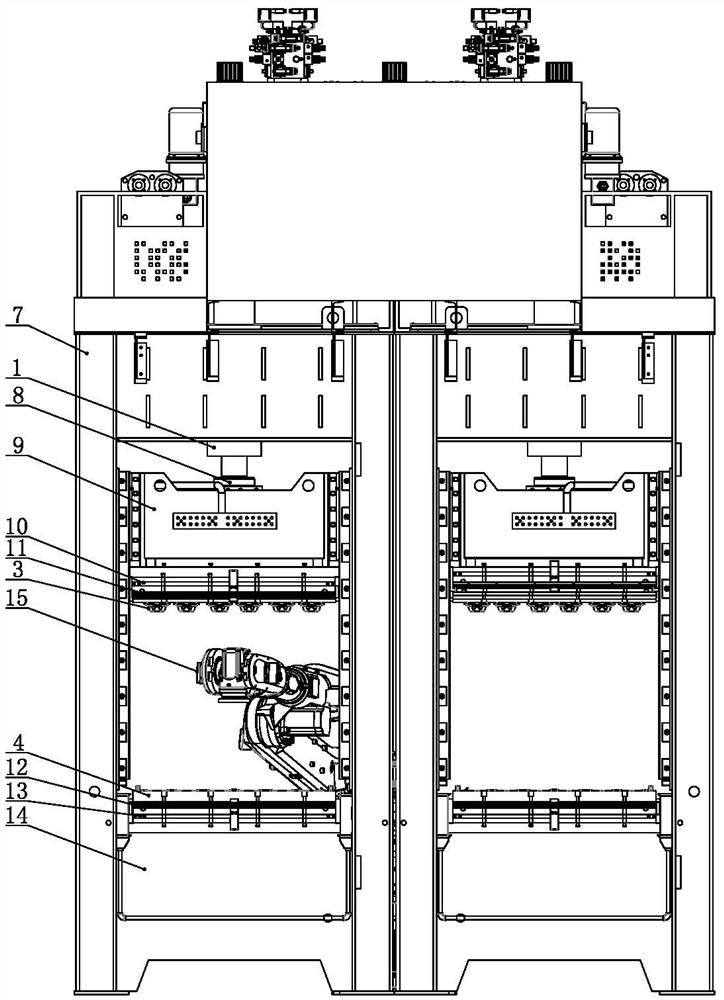

The invention relates to an environmentally friendly organic tableware wet-press forming servo pump control system, which includes a plurality of hydraulic machines sharing a feeding robot, each hydraulic machine includes four uprights, the tops of the four uprights are connected by an upper beam, and the four uprights The bottom is connected with a workbench, and sliders are installed between the upper beam and the workbench. A master cylinder is installed in the center of the upper beam, and the lower end of the plunger of the master cylinder is connected with the top of the slider. A hot-pressing upper die is installed below the upper heat-conducting oil plate; a lower heat-conducting oil plate is installed above the workbench, and a hot-pressing lower die is installed above the lower heat-conducting oil plate. A lower heat insulating plate is provided between the workbench and the lower heat conducting oil plate, an upper heat insulating plate is provided between the slider and the upper heat conducting oil plate, and a water cooling plate is provided at the joint between the plunger of the master cylinder and the sliding block. Two hydraulic machines form a row, and the two rows are set up symmetrically. This system can wet-press and heat-form the billet in a hydraulic press, and after cooling, the finished environmental-friendly organic tableware can be obtained.

Description

Environmentally friendly organic tableware wet press forming servo pump control system technical field The present invention relates to a kind of production device of environmental protection organic tableware, particularly a kind of environmental protection organic tableware wet pressing molding A servo pump control system belongs to the technical field of hydraulic machine tools. Background technique [0002] With the implementation of the country's all-round ban on plastics, products that replace plastics are springing up, while degradable, recyclable The production of green environmental protection products is inseparable from the hydraulic mother machine. At present, hydraulic presses on the market are normally driven by three-phase asynchronous motors. Constant power variable pump or servo motor drive gear pump as power source, with hydraulic cartridge valve system to realize the operation of hydraulic press control. Using a three-phase asynchronous motor to dr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C51/02B29C51/08B29C51/18B29C51/26B29C51/44B29C51/46F15B1/02F15B13/06F15B11/16B29L31/28

CPCB29C51/02B29C51/082B29C51/18B29C51/261B29C51/26B29C51/44B29C51/46F15B1/02F15B13/06F15B11/16B29L2031/286F15B2211/20584Y02P70/10

Inventor 乔礼惠

Owner 江苏扬力液压装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com