Mist spray humidifying device of opener

A technology of humidifying device and opener, which is applied in the direction of spraying device, liquid spraying device, deburring device, etc. It can solve the problems of difficult adjustment and poor fiber spray uniformity, and achieve good humidification uniformity, small pressure loss, and drainage convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

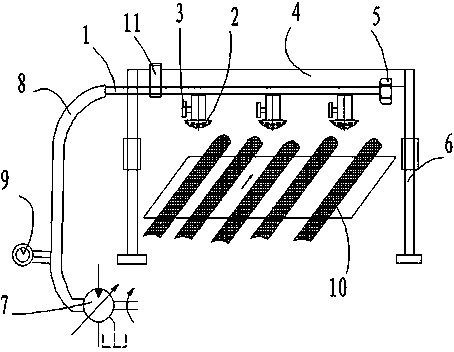

[0021] like figure 1 As shown, a spray humidification device for an opener includes a nozzle 2, a high-pressure pump 7, and a nozzle fixing pipe 1. 2 connection, the water inlet of the high-pressure pump 7 is connected to the water outlet of the water tank through the water inlet pipe, the water outlet is provided with a filter, the high-pressure pipe 8 is provided with a pressure gauge 9, the nozzle fixing pipe 1 is arranged on the fixing pipe bracket 4, The fixed pipe support 4 includes uprights 6 on both sides, and the uprights 6 on both sides are connected by an upper crossbeam, wherein the nozzle fixing pipe 1 is connected with the crossbeam, and the nozzle 2 is arranged above the scrap fiber 10, and the crossbeam is on the upright 6. Height can be adjusted. The nozzle fixing pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com