K-shaped open type big black channel steel structure and combination method

A steel structure and open technology, applied in building components, building structures, buildings, etc., can solve the problems of inconvenient assembly and installation, low stability, and difficult to master, and achieve the effect of convenient assembly and fixation and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

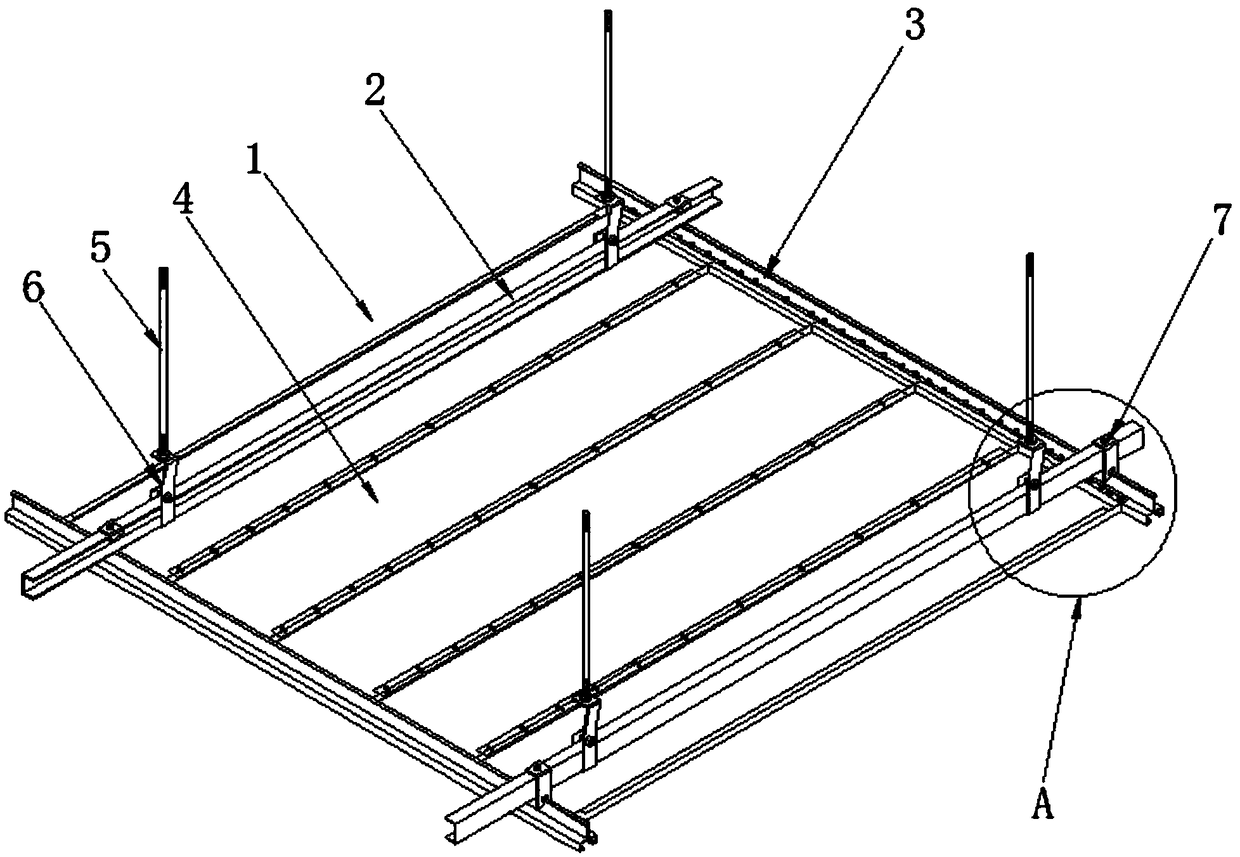

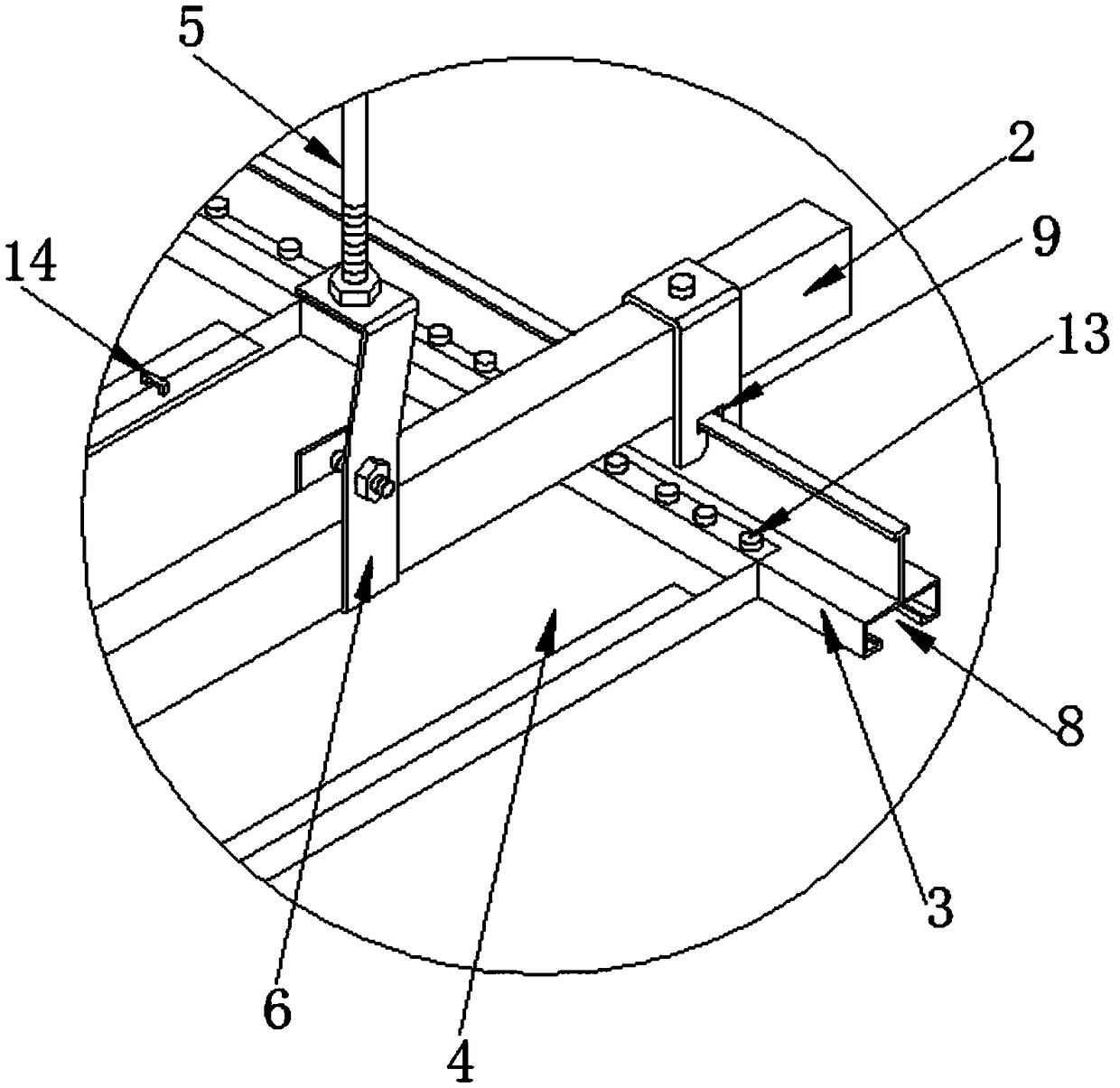

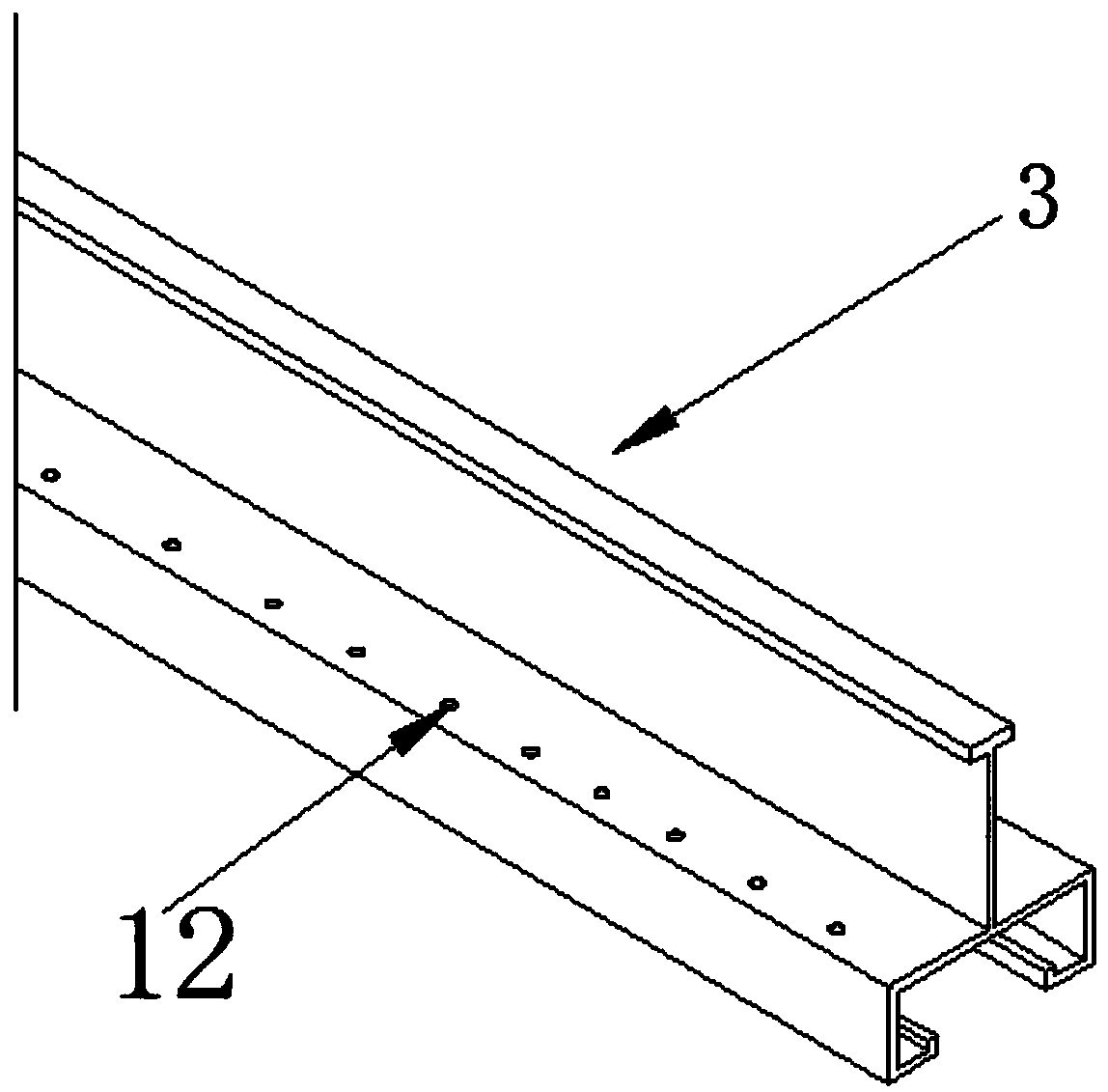

[0028] Such as Figure 1 to Figure 5 As shown, a K-shaped open large black channel steel structure provided by the embodiment of the present invention includes a ceiling structure body 1, a C-shaped light steel keel 2, a large black channel keel 3, a K-shaped open aluminum plate 4, and a suspension rod 5 , light steel keel hanger 6, big black trough keel hanger 7, big black trough 8, limit hook 9, limit round hole 10, limit square hole 11, threaded through hole 12, fixed stud 13, arch shaped card seat 14 and limit threaded hole 15, the suspended ceiling structure body 1 includes two C-shaped light steel keels 2, two large black groove keels 3 and several K-shaped open aluminum plates 4; the C-shaped light steel The upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com