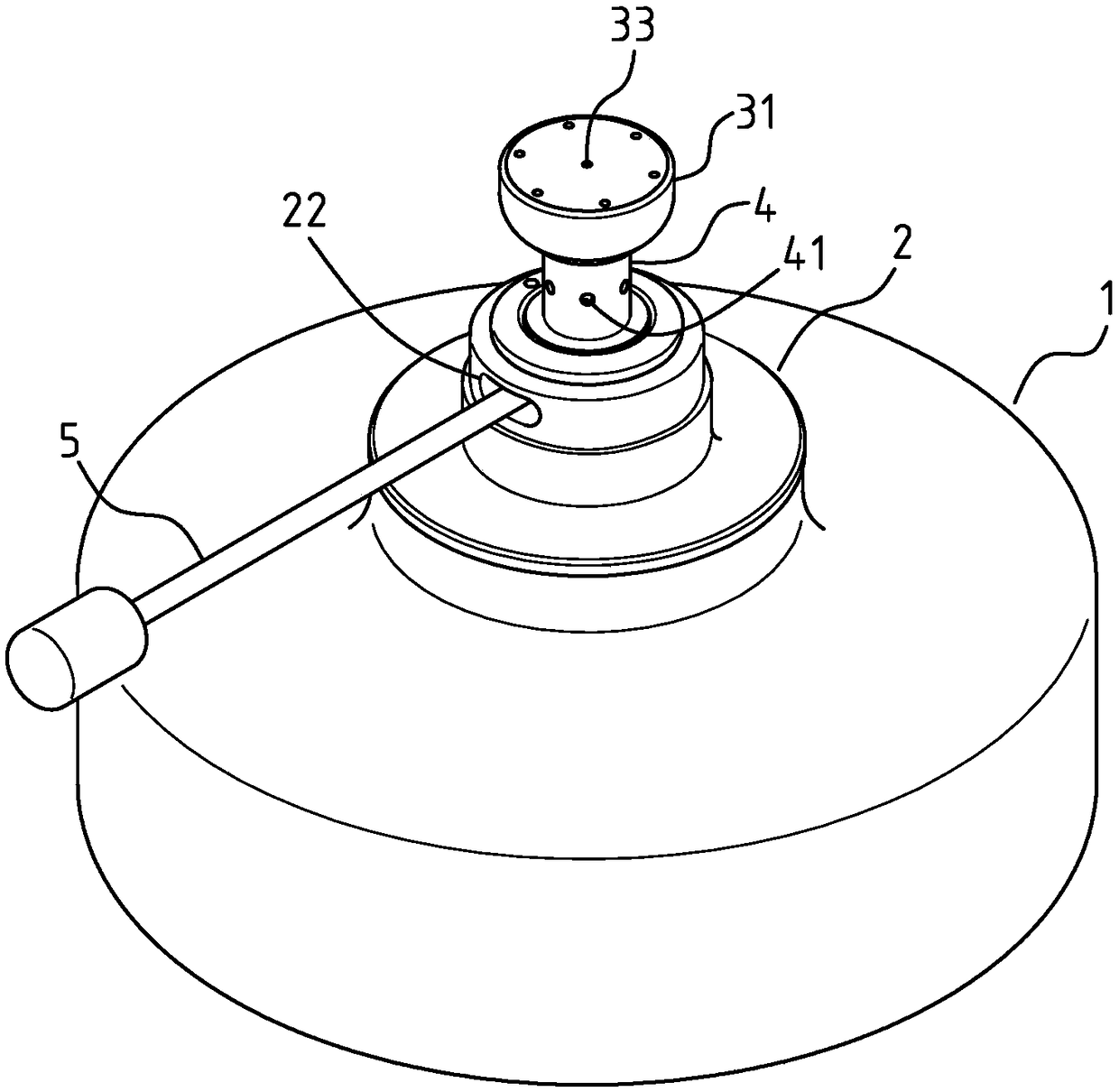

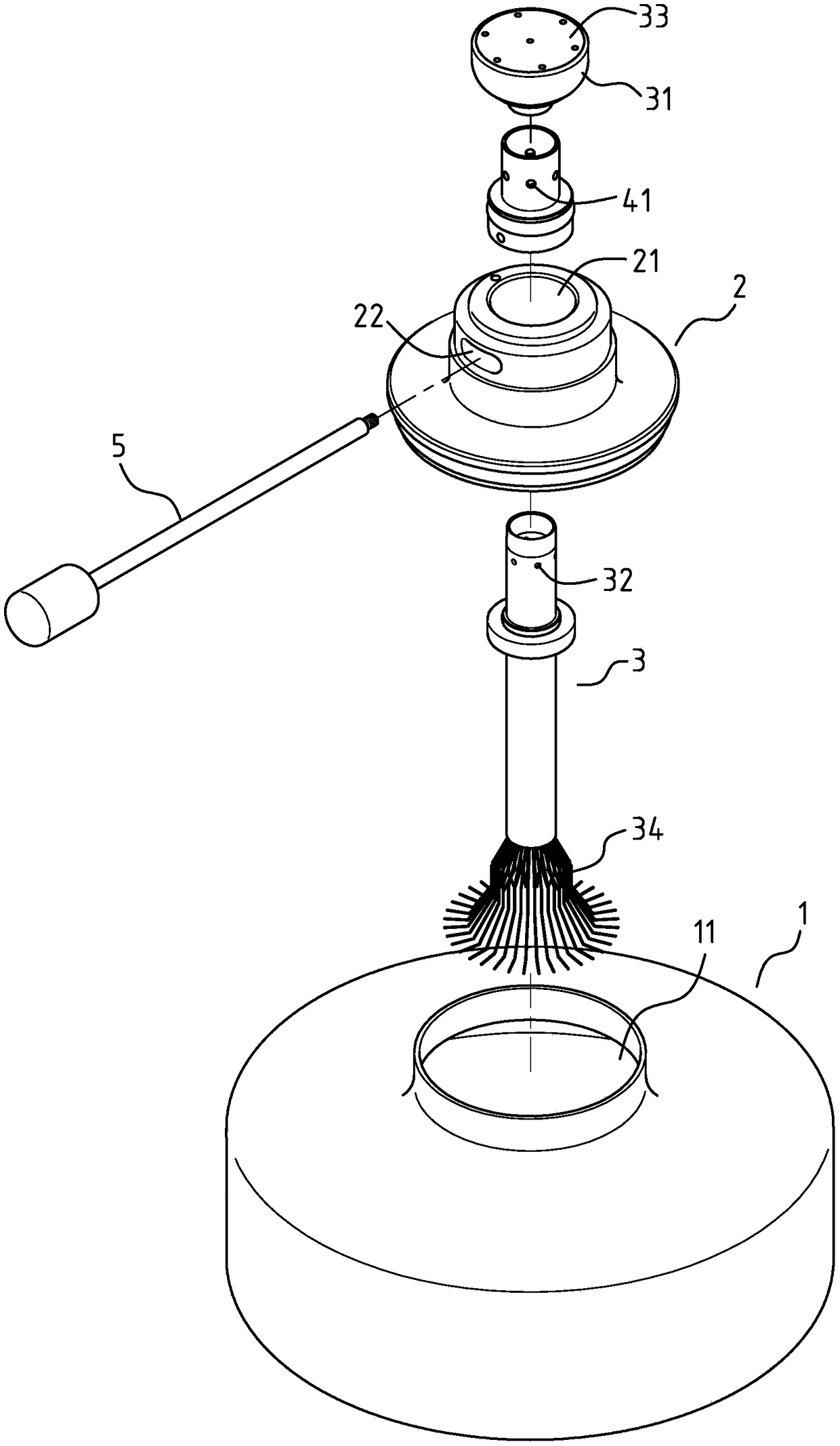

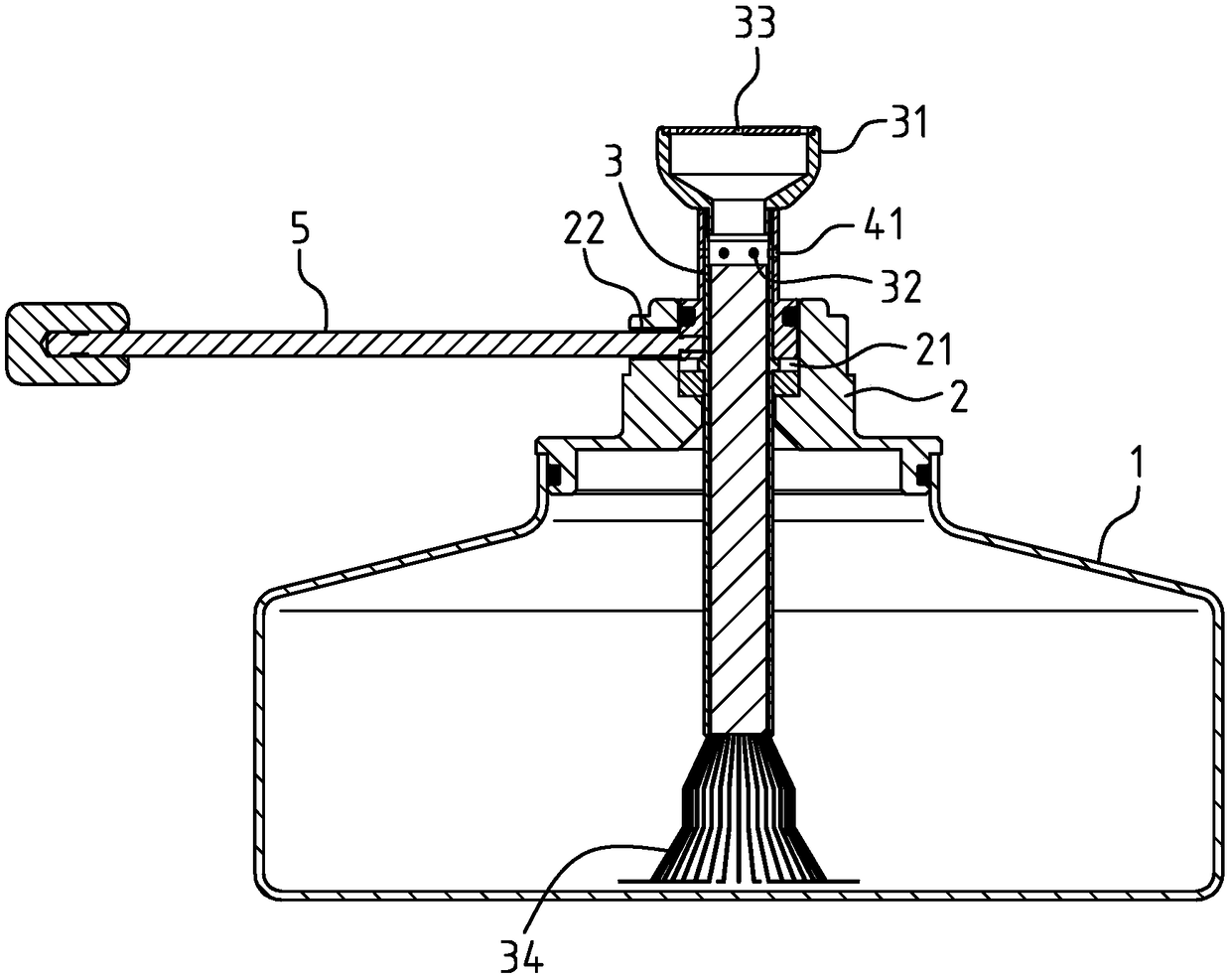

Liquid fuel furnace

A technology of liquid fuel and main tube, applied in the burner, combustion method, combustion type and other directions, can solve the problem that the alcohol lamp cannot adjust the flame size and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0032] Embodiment two is obtained by changing the foregoing embodiment one, such as Figure 4 to Figure 6 As shown, the second embodiment includes a container 1, a base 2, a main pipe 3, an adjustment member 4, an adjustment rod 5 and six auxiliary pipes 6, wherein the second embodiment has the same structure as the first embodiment, and will not To repeat the description, each of the auxiliary pipes 6 is axially arranged on the base 2 , and each of the auxiliary pipes 6 is respectively arranged around the outer periphery of the main pipe 1 .

[0033] Each of the secondary pipes 6 is respectively connected by a straight portion 61 and an arc portion 62. The straight portion 61 is arranged on the base 2, and the bottom end of the straight portion 61 extends inside the container 1. The straight portion The top end of 61 is in contact with the arc portion 62, and the arc portion 62 is in contact with the heating cap 31 at the top of the main pipe 3, and each of the secondary pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com