Patents

Literature

43results about How to "Adjust firepower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

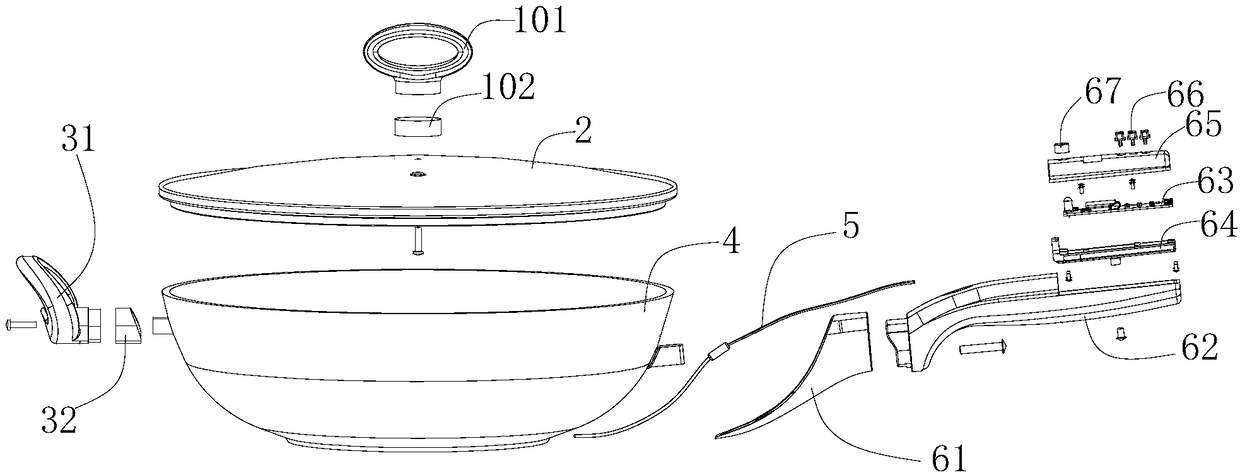

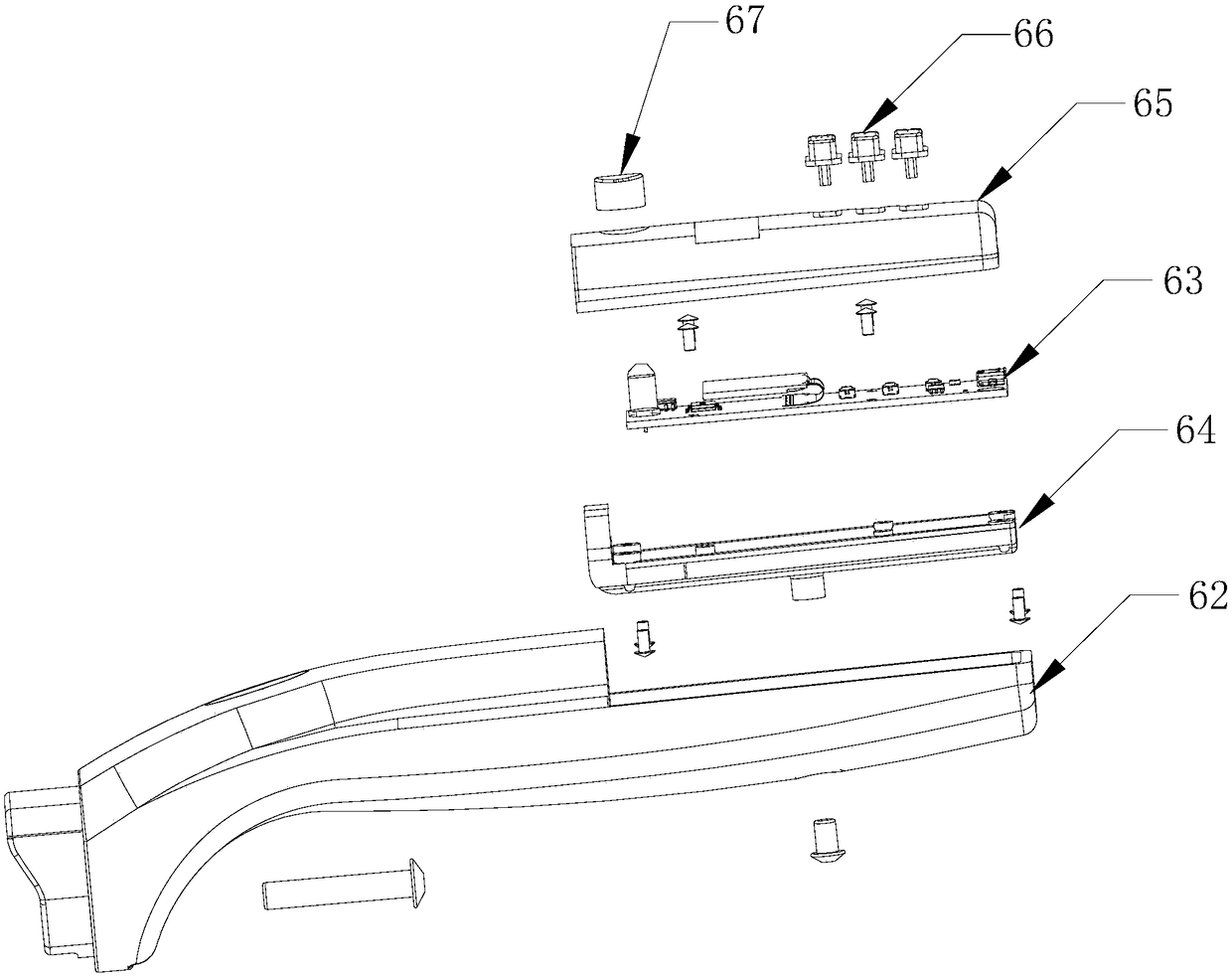

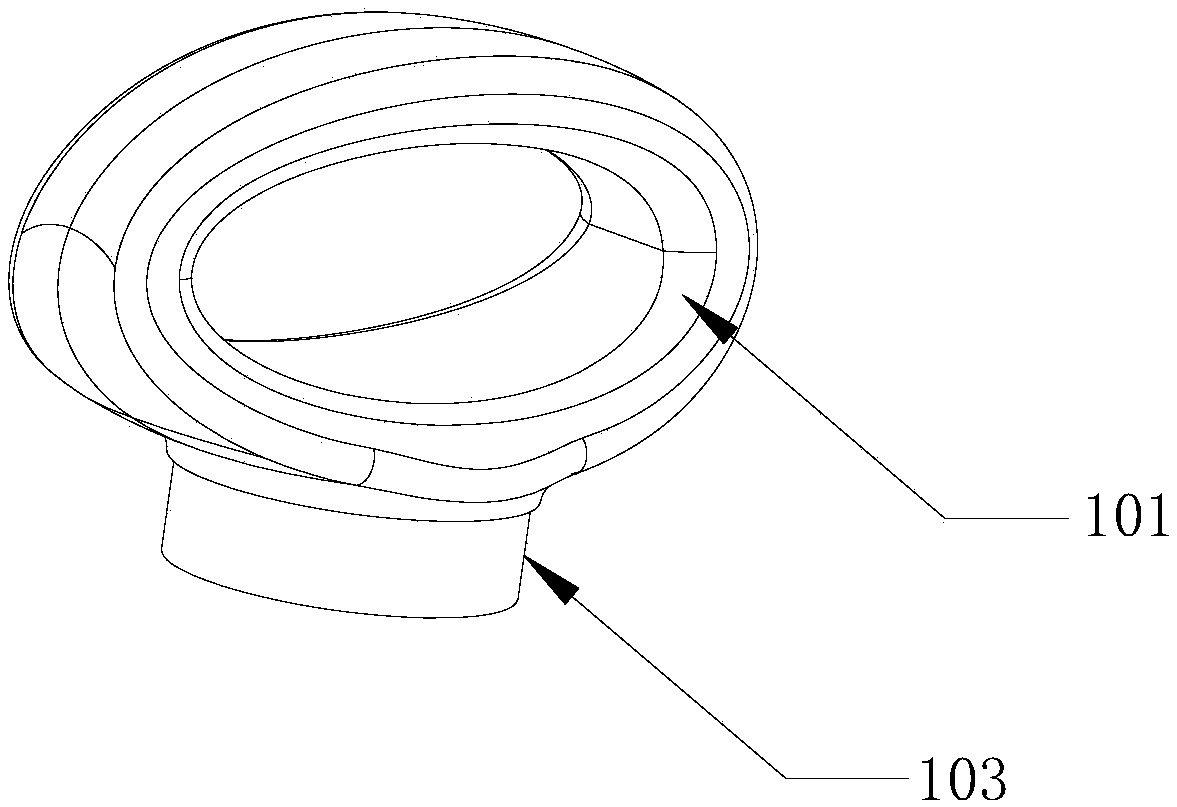

Multifunctional intelligent stir-frying pan

PendingCN108378678ASuitable for operationSafe and comfortable to holdTime-controlled ignitorsEngineeringControl circuit

The invention discloses a multifunctional intelligent stir-frying pan. The multifunctional intelligent stir-frying pan comprises a pan body and a pan cover; a cover lug is arranged on the upper surface of the pan cover; a handle and a side lug is arranged on the side surface of the pan body; the handle is provided with a temperature measuring device and an indicating lamp for reminding temperaturechange; the temperature measuring device comprises a temperature sensor probe arranged at the bottom of the pan body, a central control circuit board for receiving and processing temperature information, a timer arranged on the central control circuit board as well as a control button for controlling the indicating lamp and the timer; the temperature sensor probe is connected with the central control circuit board; and the timer and the indicating lamp are respectively connected with the central control circuit board. The temperature sensor probe of the pan is attached to the center of the pan bottom and the real-time temperature in the pan can be detected accurately; three-section lamplight is provided, so that the working state of the stir-frying pan is convenient to understand, the fire size is adjusted in real time as well as energy loss and cooking effect are avoided; and the timer and a buzzer can remind a user of the cooking time, avoids overcooking and dry firing and saves time.

Owner:XINXING XIANFENG STAINLESS STEEL PROD MFGR CO LTD

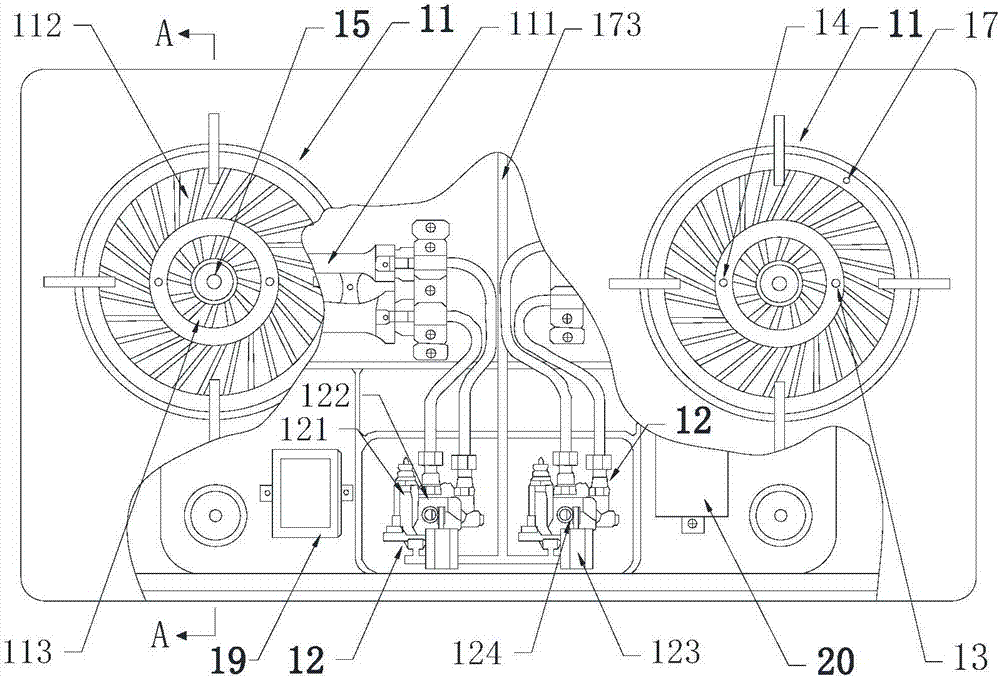

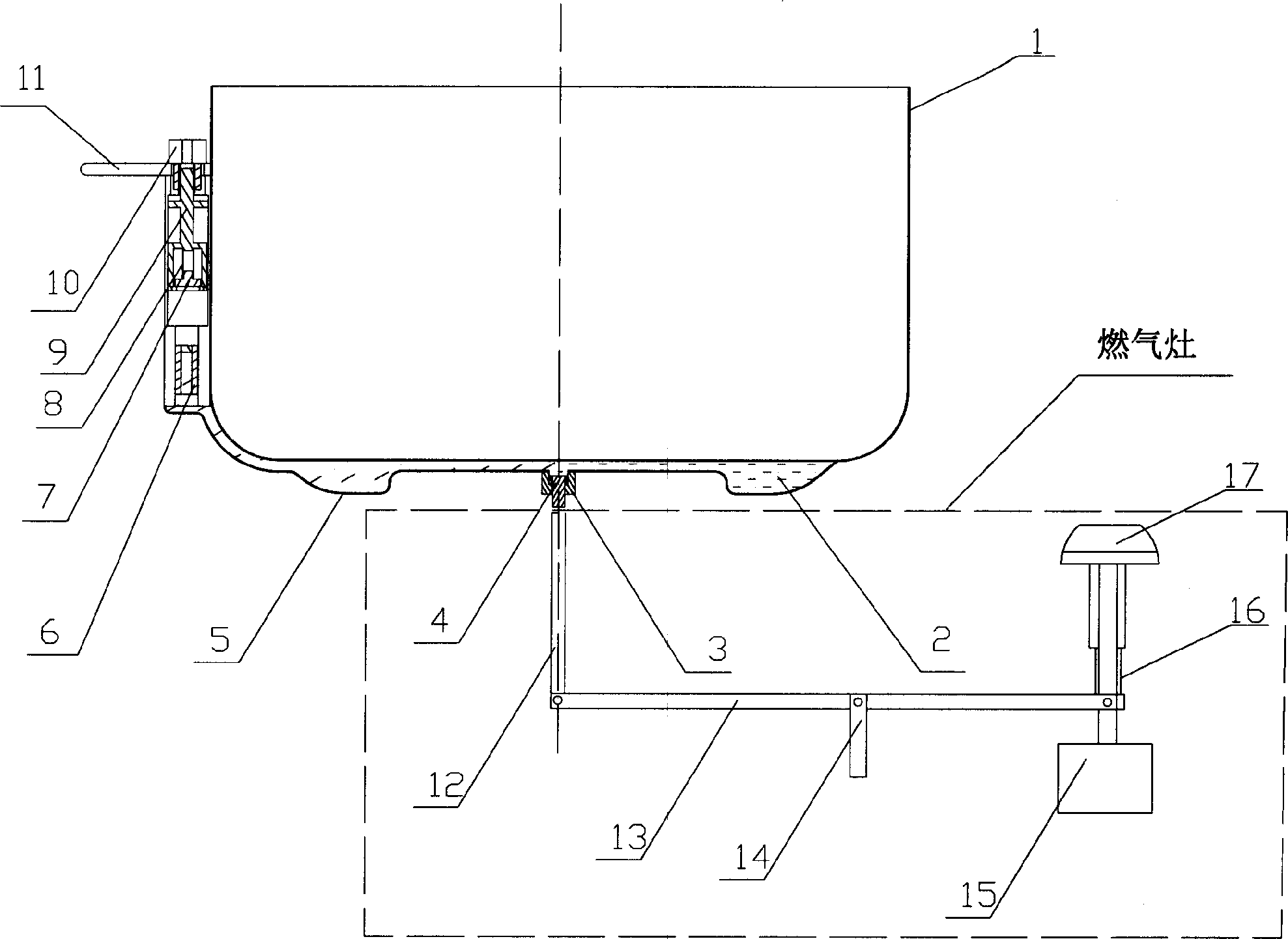

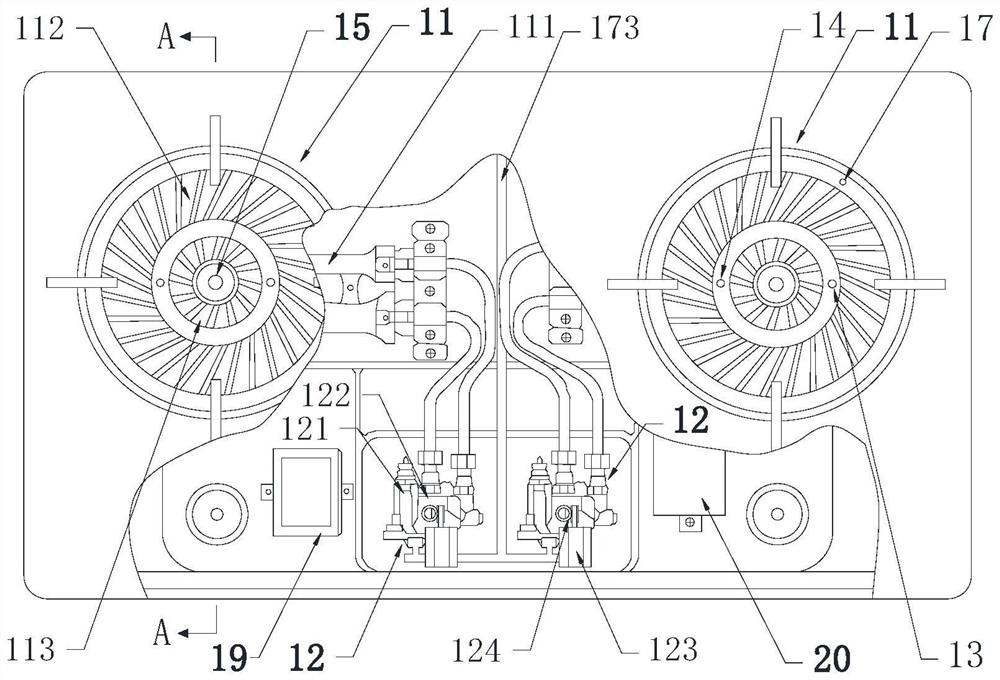

Gas stove

ActiveCN106969387AGood uniformityNot easy to burnDomestic stoves or rangesLighting and heating apparatusProcess engineeringGas transmission

The invention belongs to the field of stoves, and in particular, discloses a gas stove. The gas stove comprises a combustor, an electric control gas valve, a temperature sensor, a controller, and a cooking program positioned in the controller. An intake port of the electric control gas valve communicates with a gas transmission pipe, and an exhaust port communicates with an intake port of the combustor. The temperature sensor and the gas stove are assembled for detecting the temperature of a pan. The cooking program is set with a set value of the pan temperature associated with the time and the time. The gas stove is suitable for automatic coup cooking, rice cooking, porridge cooking and pancake cooking. During cooking of foods, the controller obtains the cooking program corresponding to the cooked foods; in the cooking process, the controller controls the electric control gas valve to adjust the firepower of the combustor according to the set value and the measured value of the pan temperature in the cooking program, so that the measured value of the pan temperature reaches the set value; and the cooking program is finished to finish cooking. In the whole cooking process, users have no need to participate, and the gas stove automatically cooks the foods, and can cook rice with rice crusts.

Owner:李明守

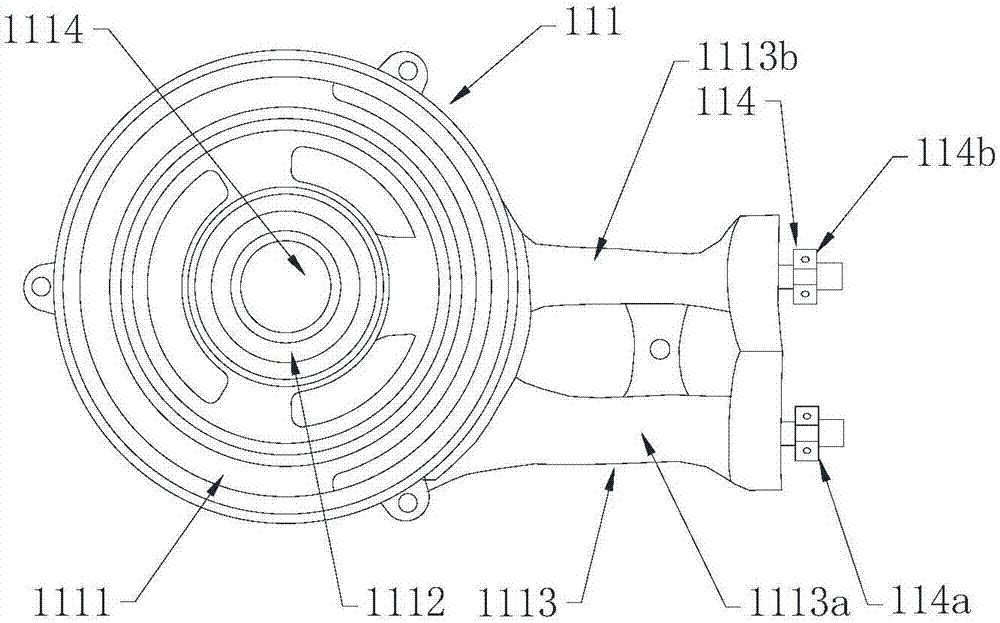

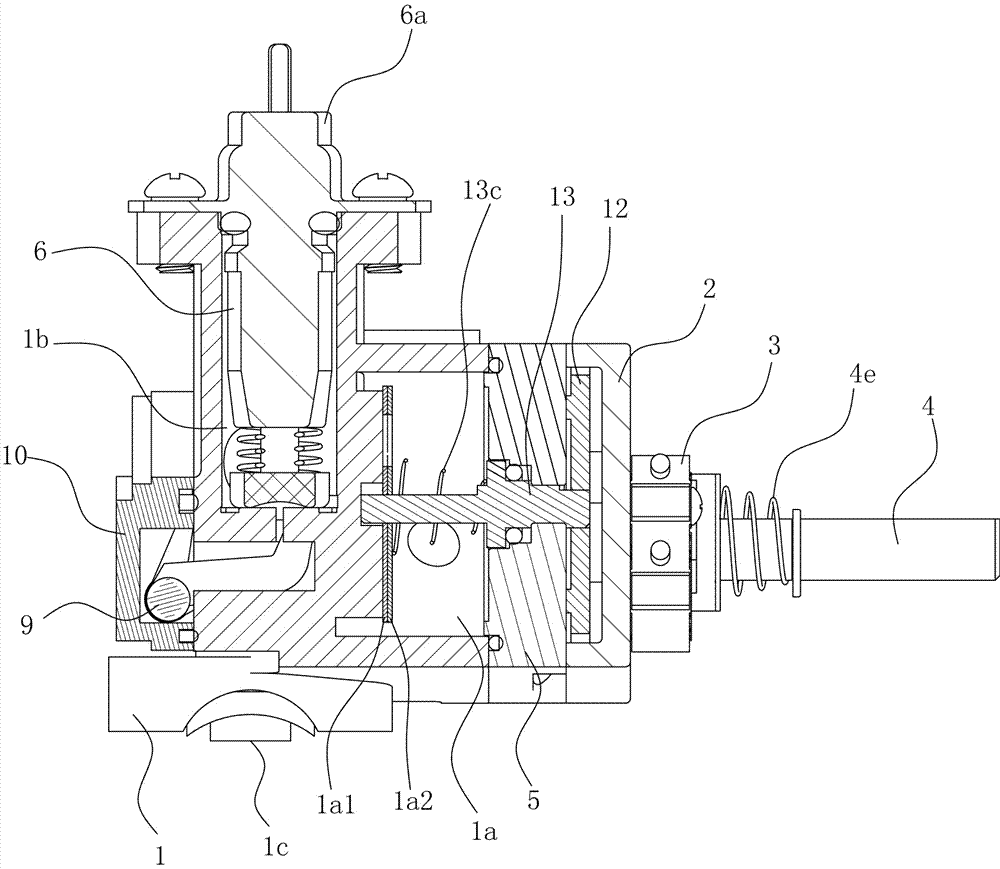

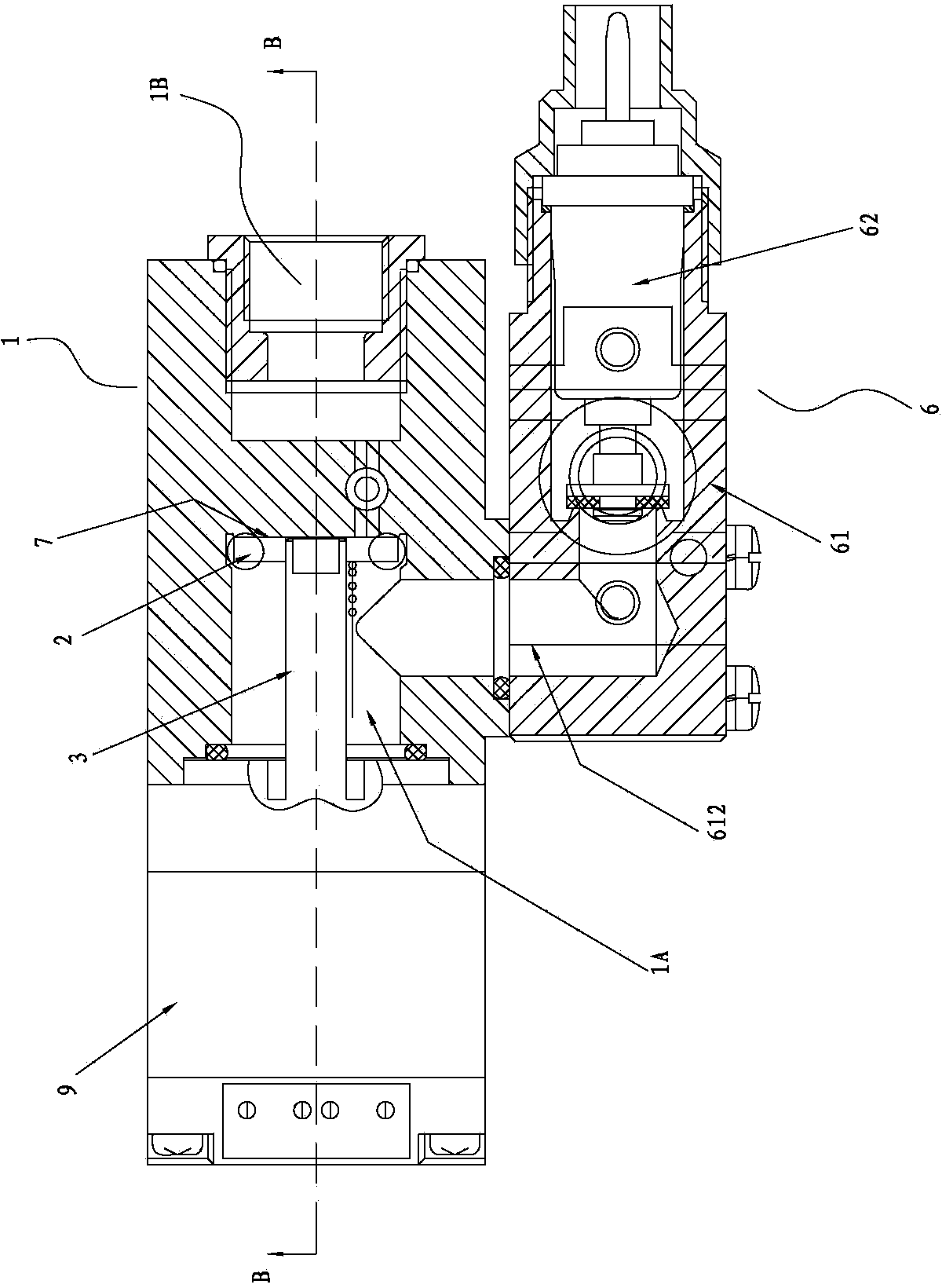

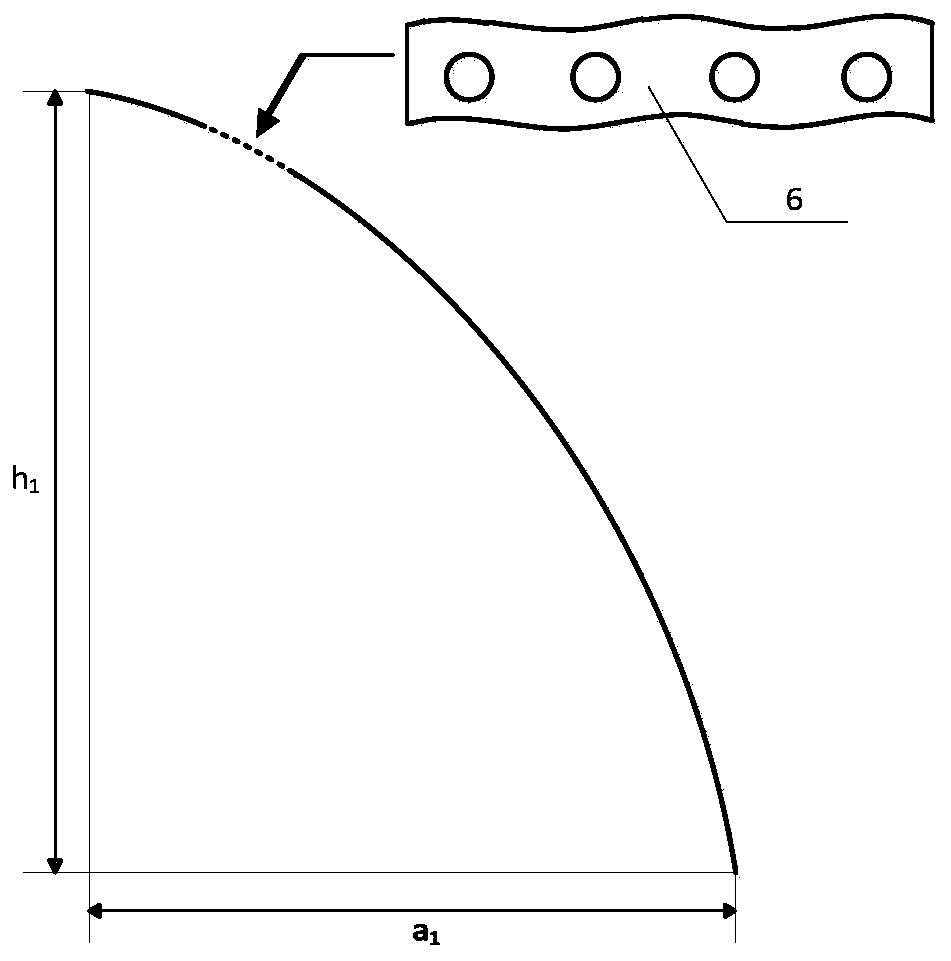

Plug valve

ActiveCN106870772AEasy to adjustAdjust firepowerDomestic stoves or rangesOperating means/releasing devices for valvesPhysicsPlug valve

The invention discloses a plug valve. A gas distributing cavity is additionally arranged on a valve body of the plug valve; a gas distributing plate is arranged in the gas distributing cavity; a vent hole is formed in the gas distributing plate; a gas distributing slot which communicates with the vent hole is formed in at least one side, in the rotation direction of the gas distributing plate, of the vent hole; the gas distributing slot extends in the rotation direction of the gas distributing plate; when the gas distributing slot and the vent hole rotate along with the gas distributing plate, a gas inlet which is formed in the gas distributing cavity and communicates with a gas source can be partially or completely covered; and the gas distributing plate is connected with a valve element through a transmission device, and synchronously rotates with the valve element. The shape of the gas distributing slot can be set, so that gas outlet is kept consistent within certain rotation angle, and therefore, a user conveniently regulates fire power of a gas stove, and does not need to stare at fire all the time to slowly regulate like a mode of regulating firepower by a conventional fuel gas valve.

Owner:ZHEJIANG XINTAO ELECTRONICS MACHINERY

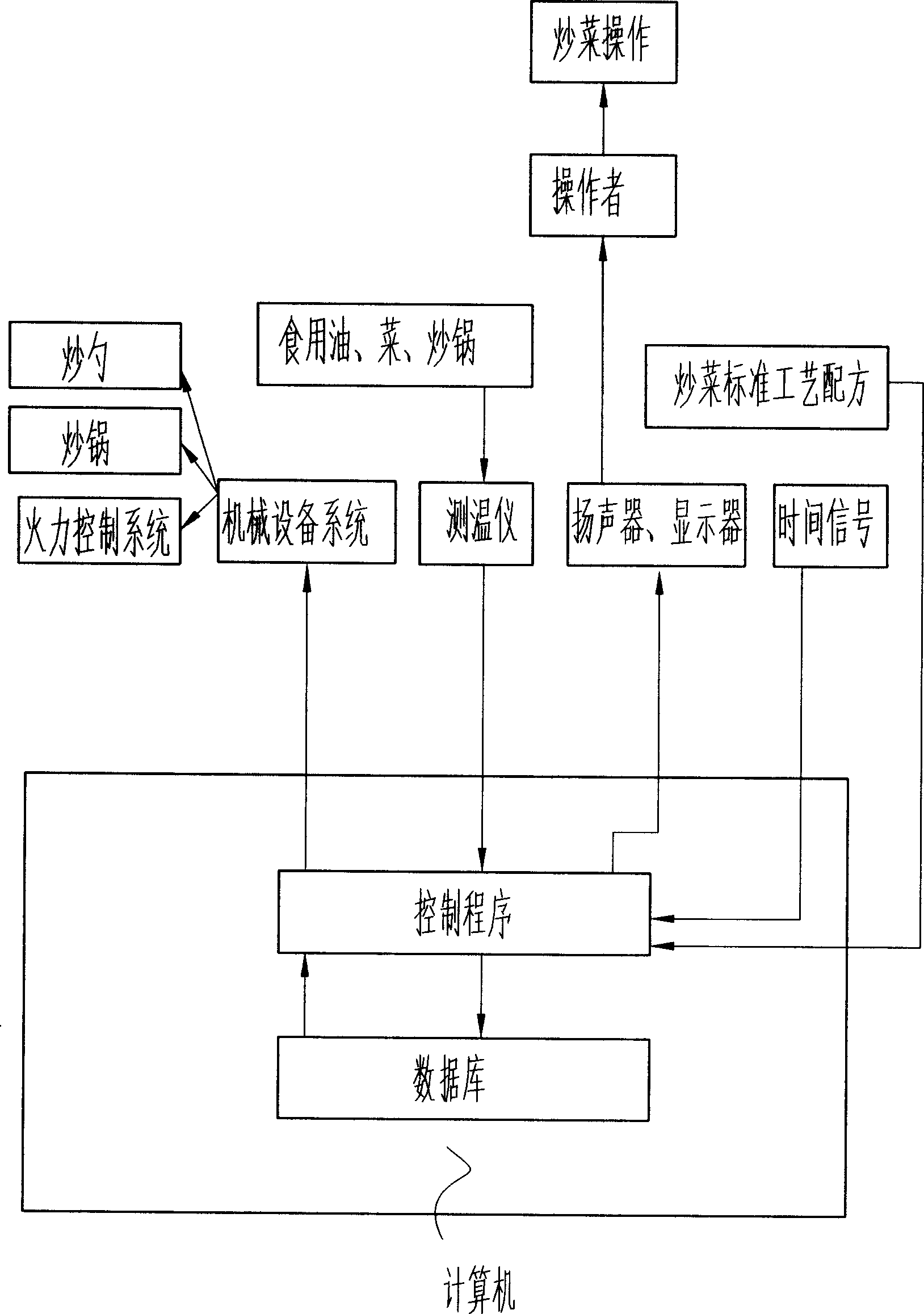

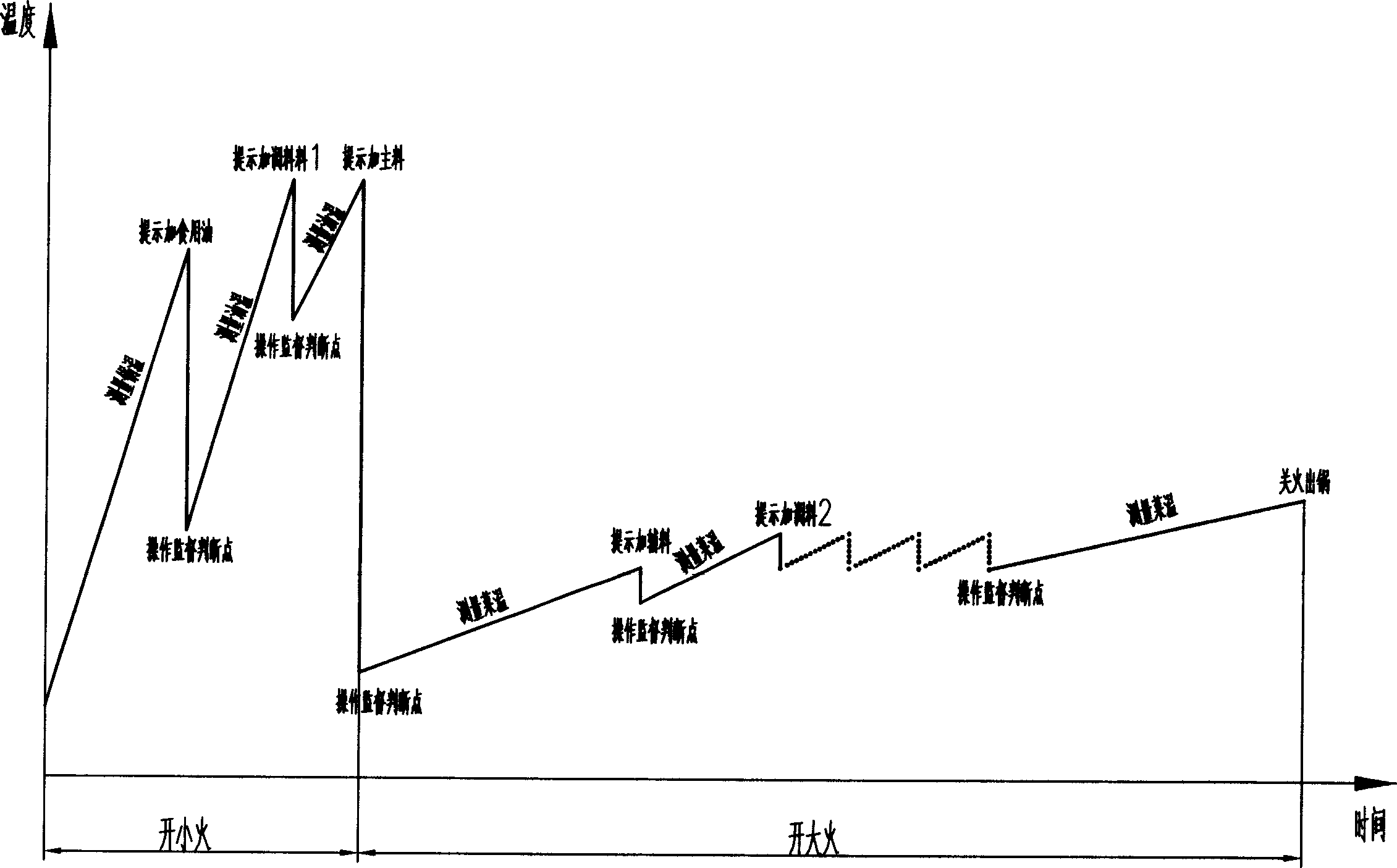

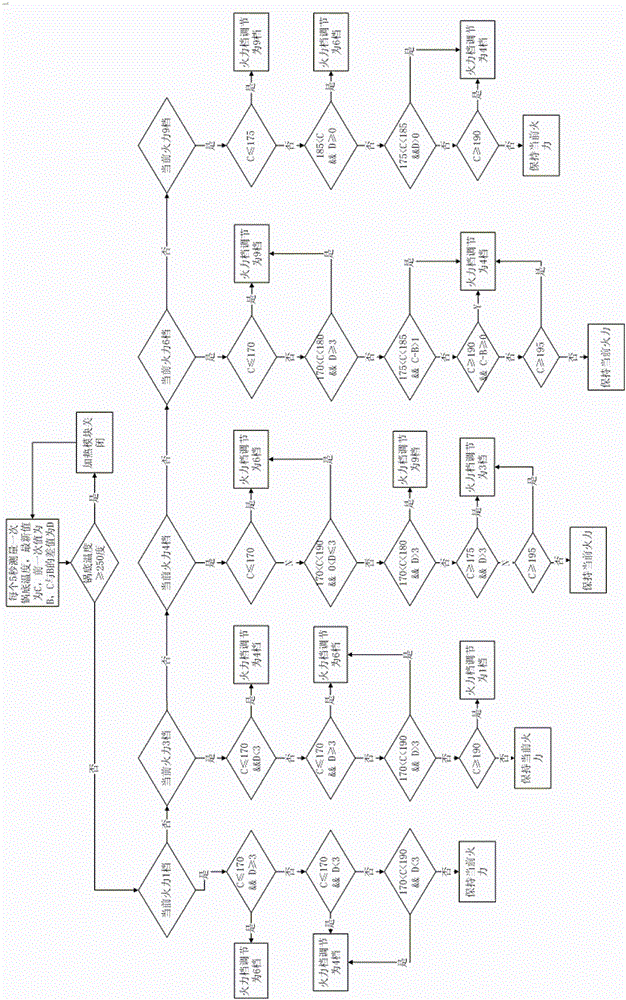

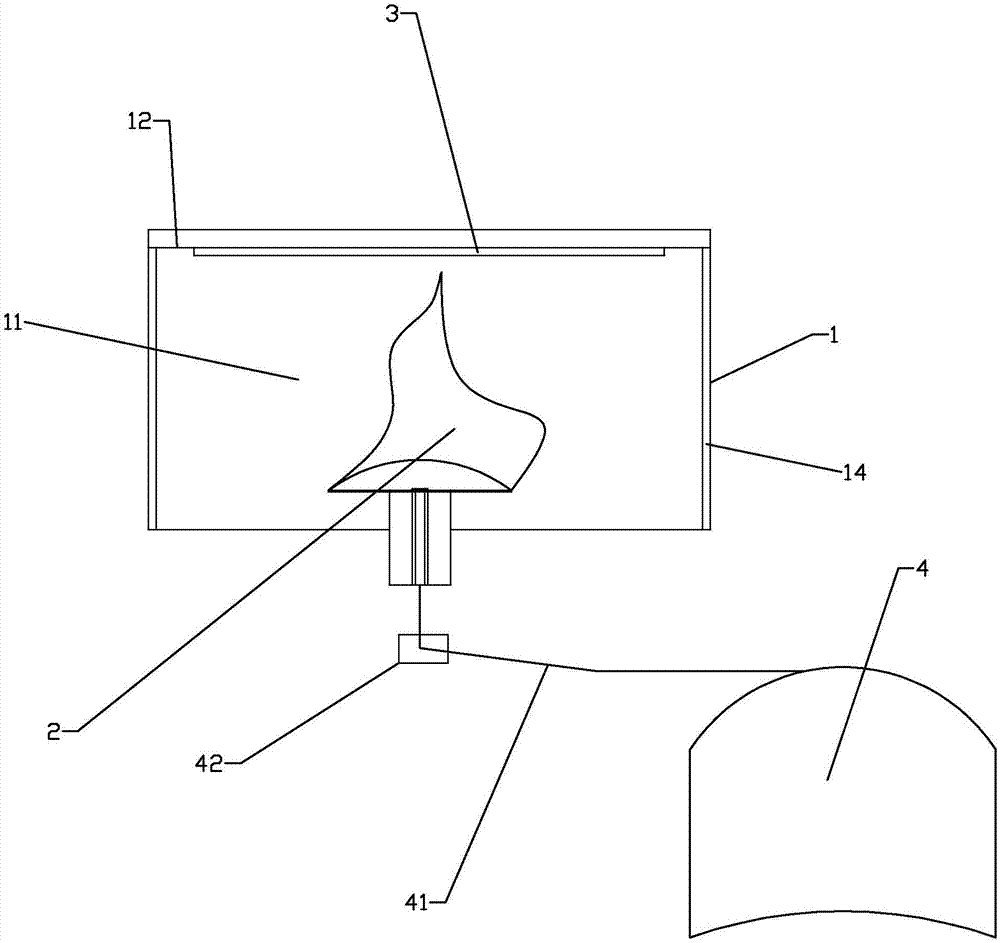

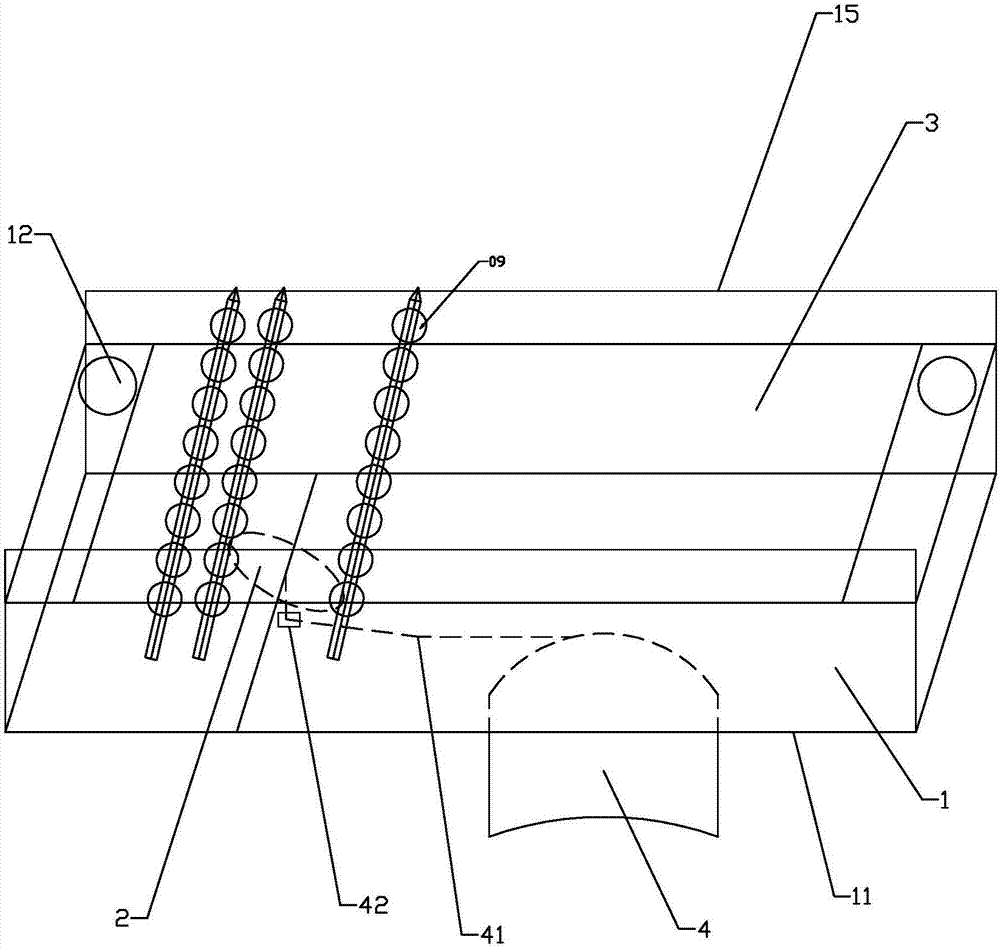

Chinese dish cooking process

InactiveCN1644084AAchieve graspAdjust firepowerProgramme controlComputer controlLoudspeakerCooking process

A technology for frying the Chinese dish features that each Chinese dish has its standard prescription and under the control and prompting of computer, the whole frying procedure is conducted by cook. The pot temp, oil temp, dish temp and frying time are sensed by computer and relative instructions are sent to the cook via loudspeaker. If the exception occurs, an alarm is generated by computer.

Owner:BEIJING SHEENLINE GRP CO LTD

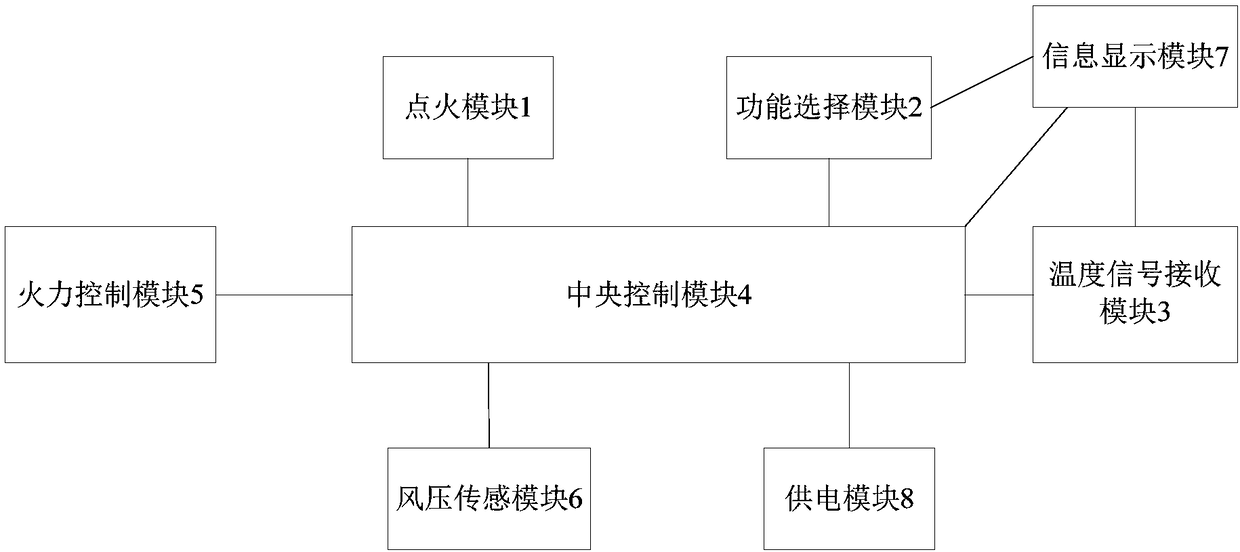

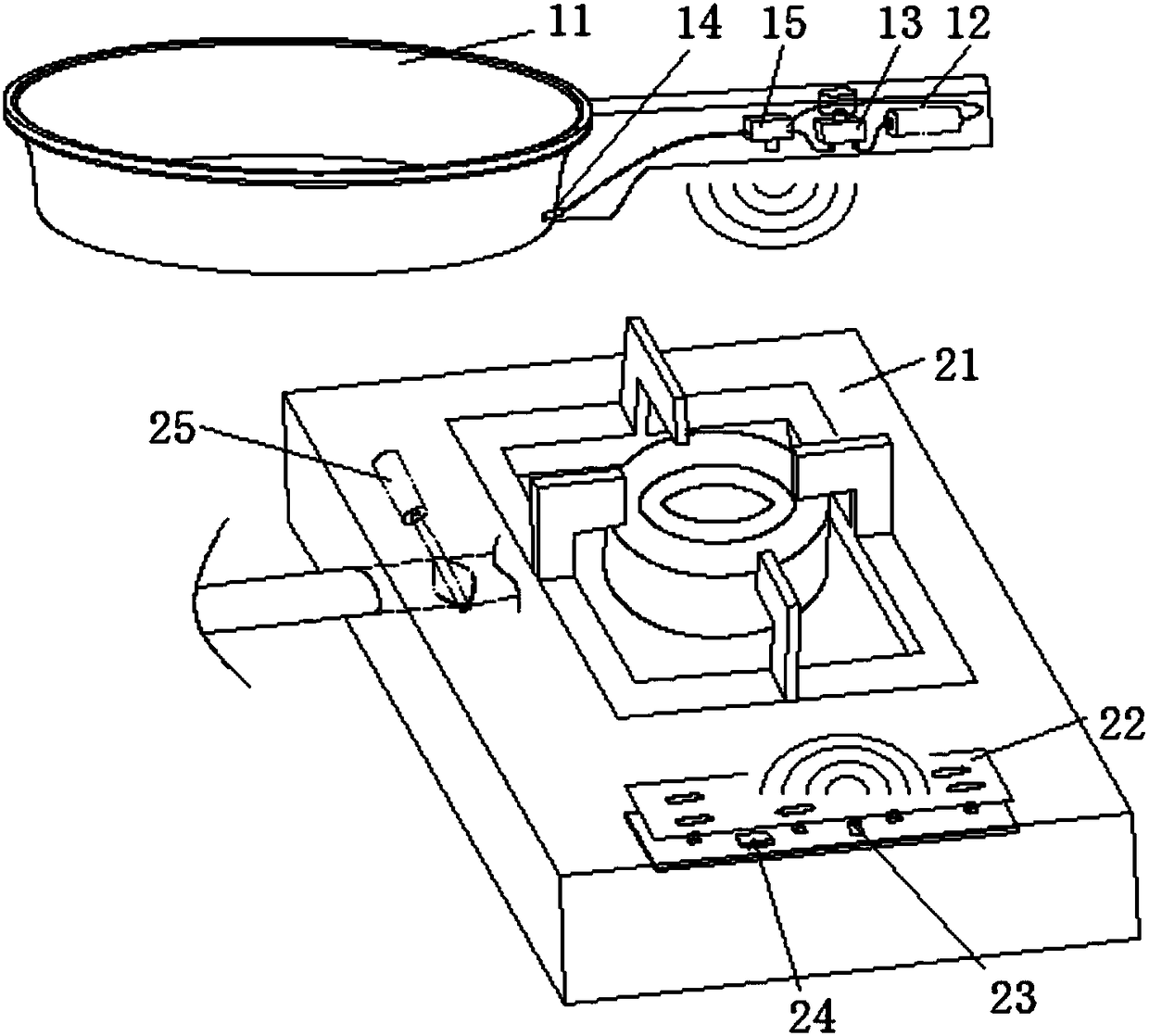

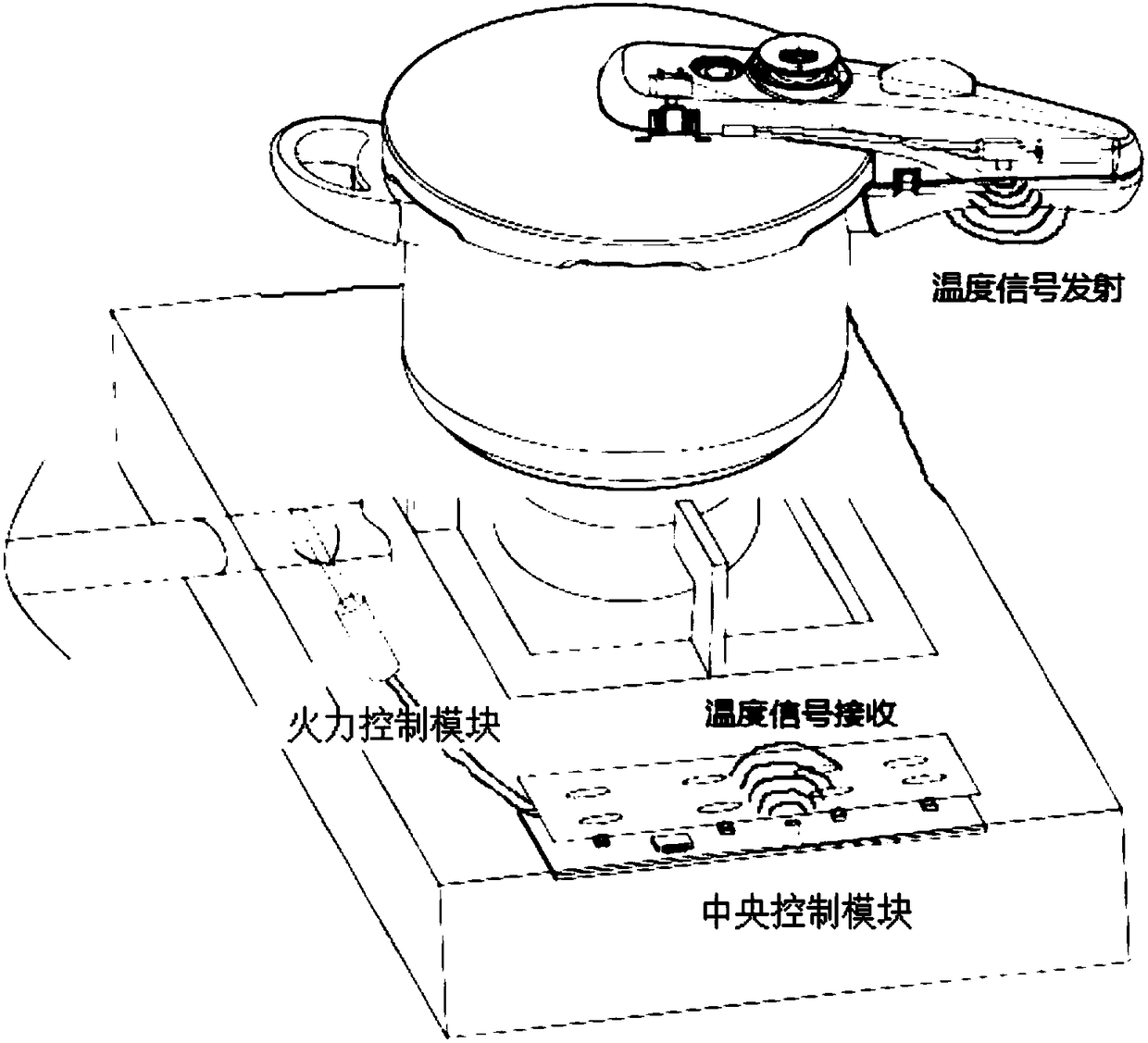

Intelligent cooker and intelligent kitchenware system

InactiveCN108534188AAdjust firepowerGuaranteed to be nutritious and deliciousDomestic stoves or rangesLighting and heating apparatusElectricityTemperature control

The invention provides an intelligent cooker and an intelligent kitchenware system. The intelligent cooker comprises an ignition module, a function selecting module, a temperature signal receiving module, a central control module and a fire control module, the ignition module ignites and starts the intelligent cooker to work, the function selecting module selects needed cooking functions and determines needed temperature ranges, the temperature signal receiving module receives cooker temperature signals sent by the cooker and transmits the same to the central control module, the central control module determines fire adjusting values according to the needed temperature ranges and the cooker temperature signals, and the fire control module controls supply quantity of gas according to the fire adjusting values. By adopting the intelligent cooker and the intelligent kitchenware system, whole-process intelligent temperature control and cooking can be realized, and optimal cooking temperature of food in the cooker can be ensured; the intelligent cooker and the intelligent kitchenware system have the advantages that electricity and water are saved, the food is ensured to be nutritional and delicious, and environment is maintained clean, and competitiveness of the intelligent cooker and the intelligent kitchenware system in similar products is improved.

Owner:浙江厨必爱电器有限公司

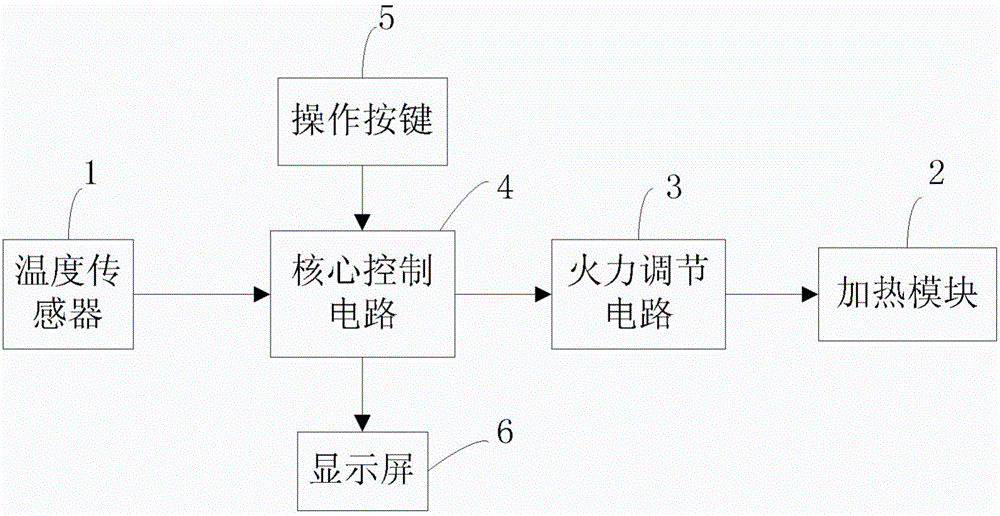

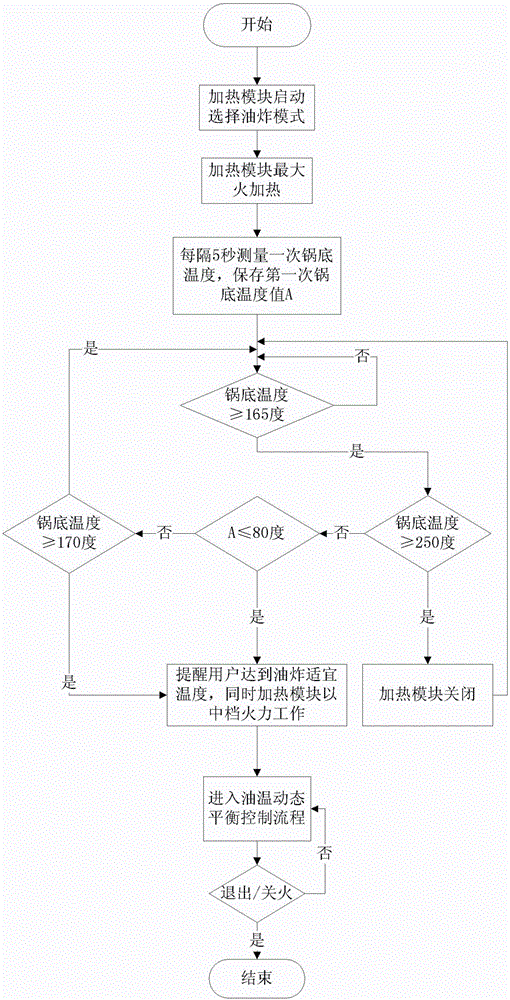

Heating cooking equipment and oil temperature control method thereof

ActiveCN106551633AAdjust the firepower in timeAdjust firepowerDeep fat fryersDynamic balanceEngineering

The invention relates to heating cooking equipment and an oil temperature control method of the heating cooking equipment. The heating cooking equipment comprises a temperature sensor, a heating module, a firepower adjusting circuit and a core control circuit, wherein the temperature sensor is used for detecting the temperature of the bottom of a pan in real time, the firepower adjusting circuit is used for adjusting the firepower of the heating module, the core control circuit for controlling the firepower adjusting circuit is connected with the firepower adjusting circuit, and the temperature sensor is connected with the core control circuit. The heating cooking equipment is characterized in that a frying working mode is set in the core control circuit; after the frying working mode is enabled, the core control circuit measures the temperature of the bottom of the pan in real time through the temperature sensor, then the heating module works in the maximum fire state till the temperature, detected in real time, of the bottom of the pan reaches the preset appropriate frying temperature interval, then the oil temperature dynamic balancing control process is entered, and the temperature of the bottom of the pan is kept in the preset appropriate frying temperature interval all the time till the frying working mode is exited or the heating module is closed. The heating cooling equipment and the oil temperature control method have the beneficial effects that the frying working mode is provided, the oil temperature can be controlled precisely, and use is convenient.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

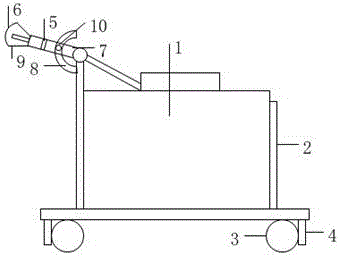

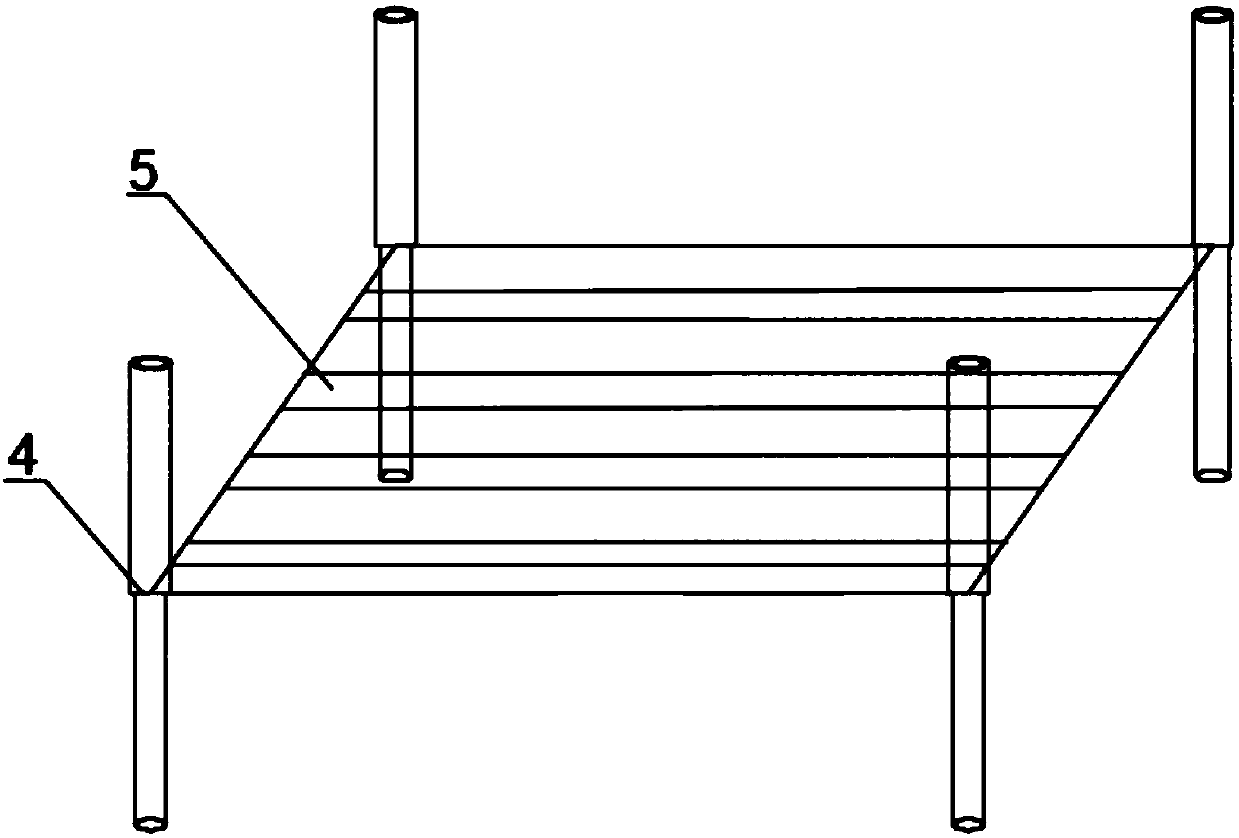

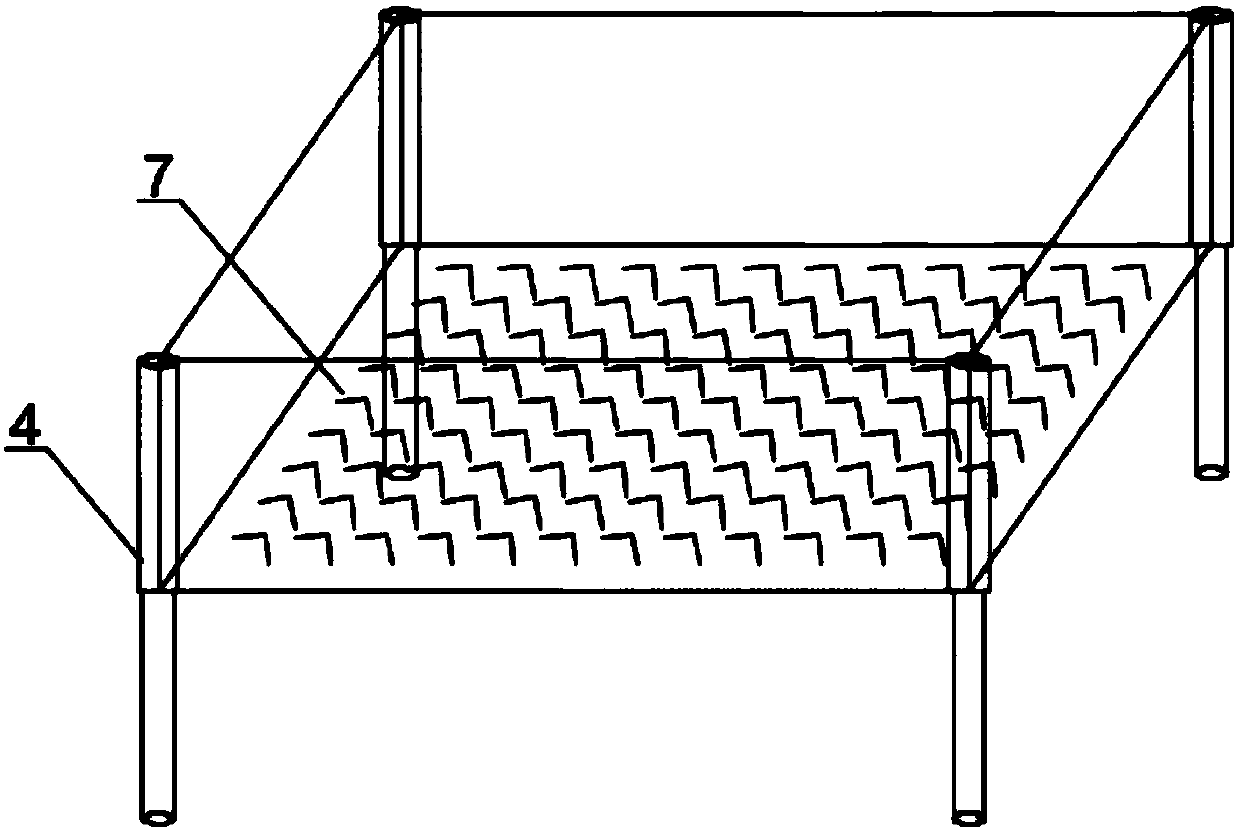

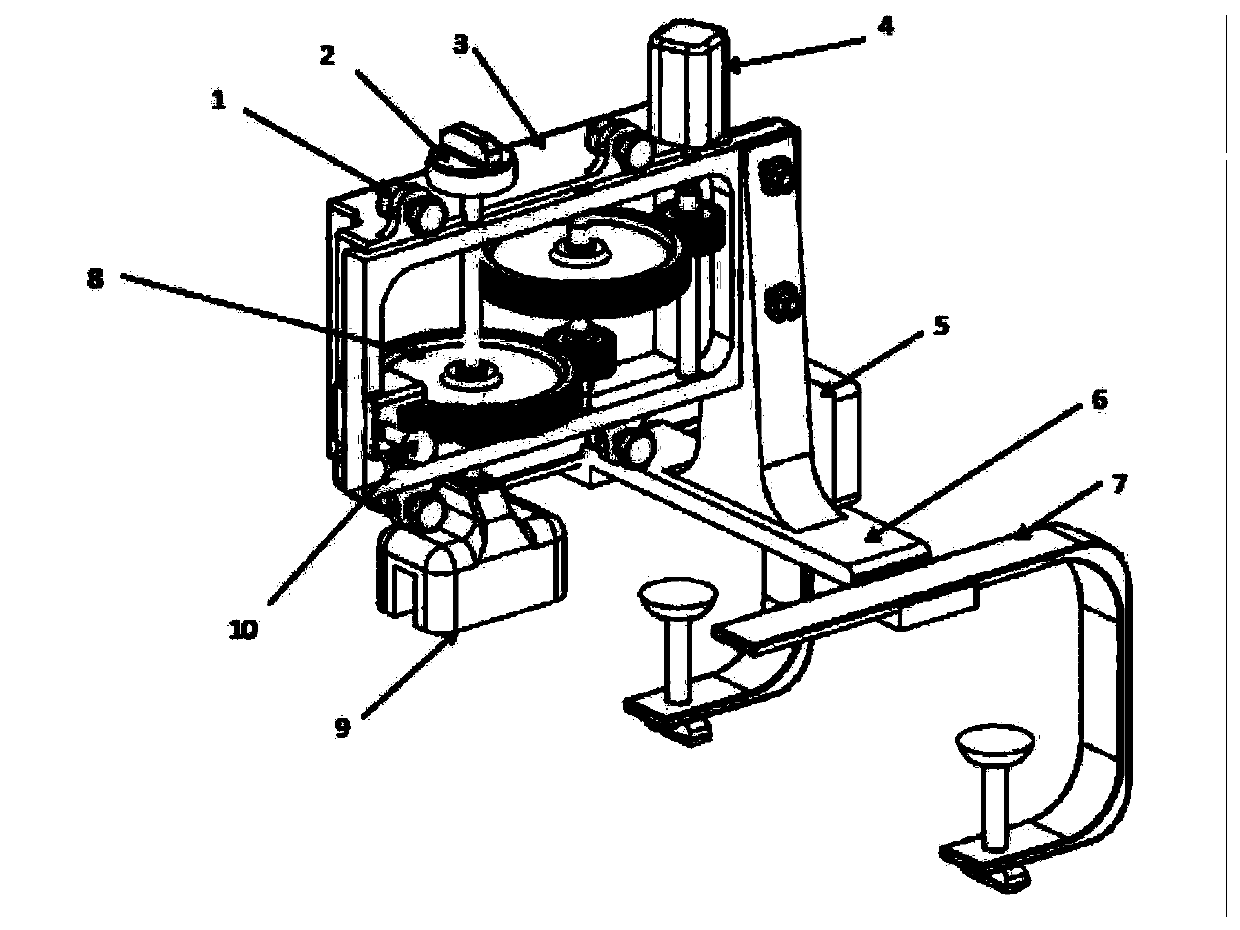

Metal fuel gas singeing machine

The invention discloses a metal fuel gas singeing machine. The metal fuel gas singeing machine is characterized by comprising a gas tank, a metal sheet, a flaming gun and an engine base, wherein a rolling wheel and a brake pad are arranged at the bottom of the engine base; a rubber sleeve is arranged at the periphery of the outer side of the rolling wheel; the rubber sleeve is provided with friction lines; a clamping frame is arranged above the engine base; the gas tank is arranged in the clamping frame; one end of the flaming gun is movably fixed above the clamping frame; a gun body of the flaming gun is provided with a convex screw rod; the screw rod is clamped into an arc-shaped clamping groove above the clamping frame and can be fixed in any point through a nut; the metal sheet is fixed at a gun opening of the flaming gun through two or more than two connection rods; a plane formed by contact points of the connection rods and the metal sheet is vertical to the direction of the gun opening of the flaming gun. The gas tank is adopted and is convenient to replace and transport; the bottom end of the flaming gun is movably fixed above the clamping frame and the screw rod is clamped into the arc-shaped clamping groove above the clamping frame, so that the angle can be adjusted in the clamping groove so as to be adaptive to materials from various directions.

Owner:丁灏

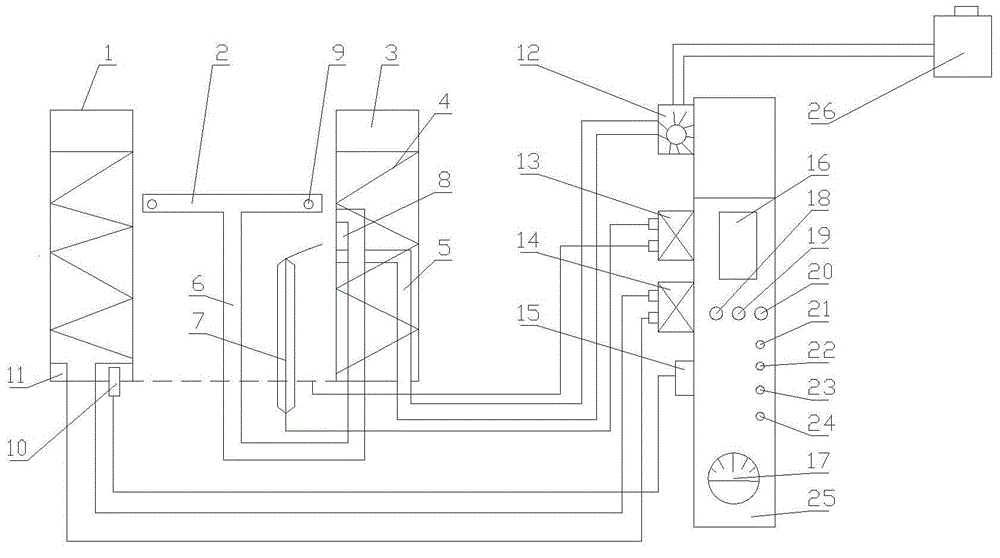

Automatic control alcohol-based fuel gasification burner and preparation method thereof

InactiveCN104930503ANo cloggingNo emissionsBurnersBurner control devicesAutomatic controlExhaust gas emissions

The invention relates to an automatic control alcohol-based fuel gasification burner and a preparation method thereof. The burner comprises a furnace cylinder, and a fuel gas nozzle provided with gas vents and disposed inside the furnace cylinder. The burner is characterized in that the furnace cylinder is a cylindrical object formed by two coaxial hollow cylinders and provided with a sealing chamber; the sealing chamber is internally provided with a heating chamber; the heating chamber is provided with a cracking chamber and an electrical thermocouple; the cracking chamber is provided with a gasification pipe connected to the lower end of the fuel gas nozzle and an oil inlet pipe connected to an oil pump; the oil pump is connected to an oil tank; and the furnace cylinder is also internally provided with an electronic ignition needle connected in a micro computer controller. According to the invention, the temperature in the heating chamber is controlled by the micro computer controller, and the temperature can be kept at a range from 65 DEG.C to 250 DEG.C, so that the cracked fuel can always be kept in a gas state, the fuel gas nozzle cannot be blocked, the gas can be sufficiently burned, almost no exhaust gas is discharged, the atmospheric environment is protected, the calorific value is greatly increased, the energy consumption is reduced, the ignition can be completed through a one-key start manner, and the operation is easy.

Owner:天津恒远科创新能源科技有限公司

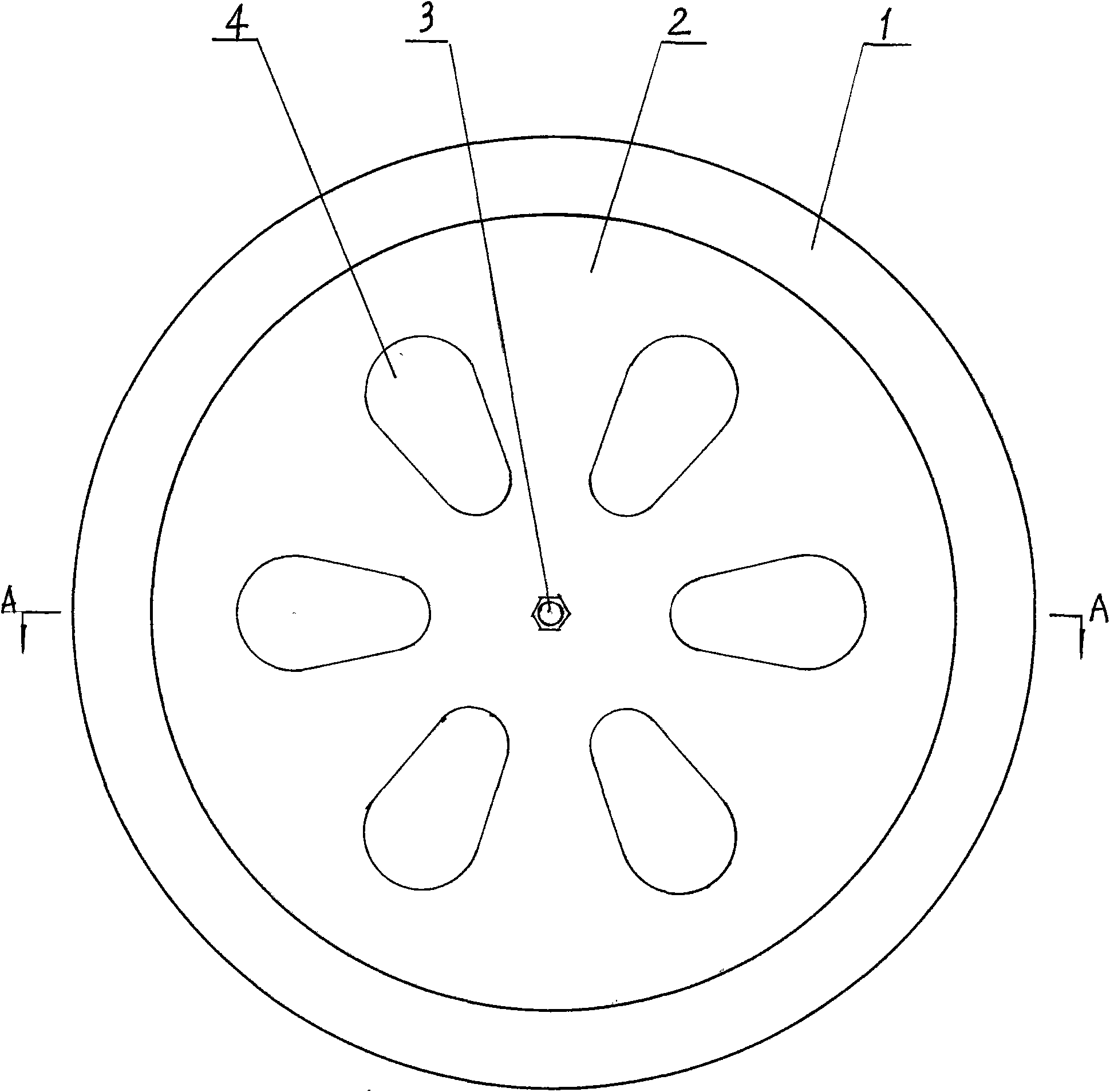

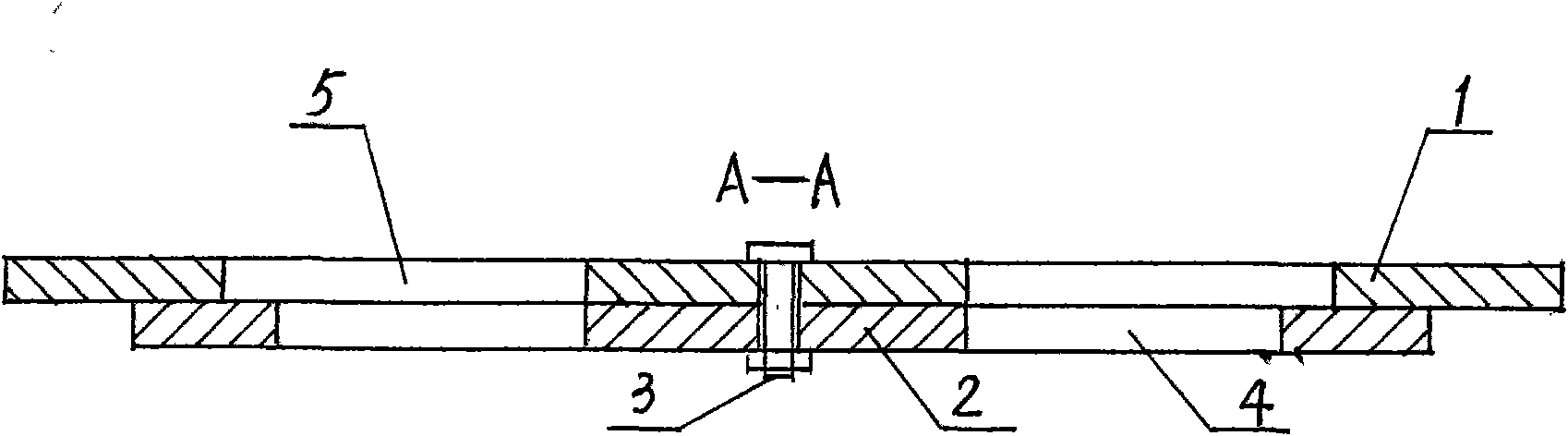

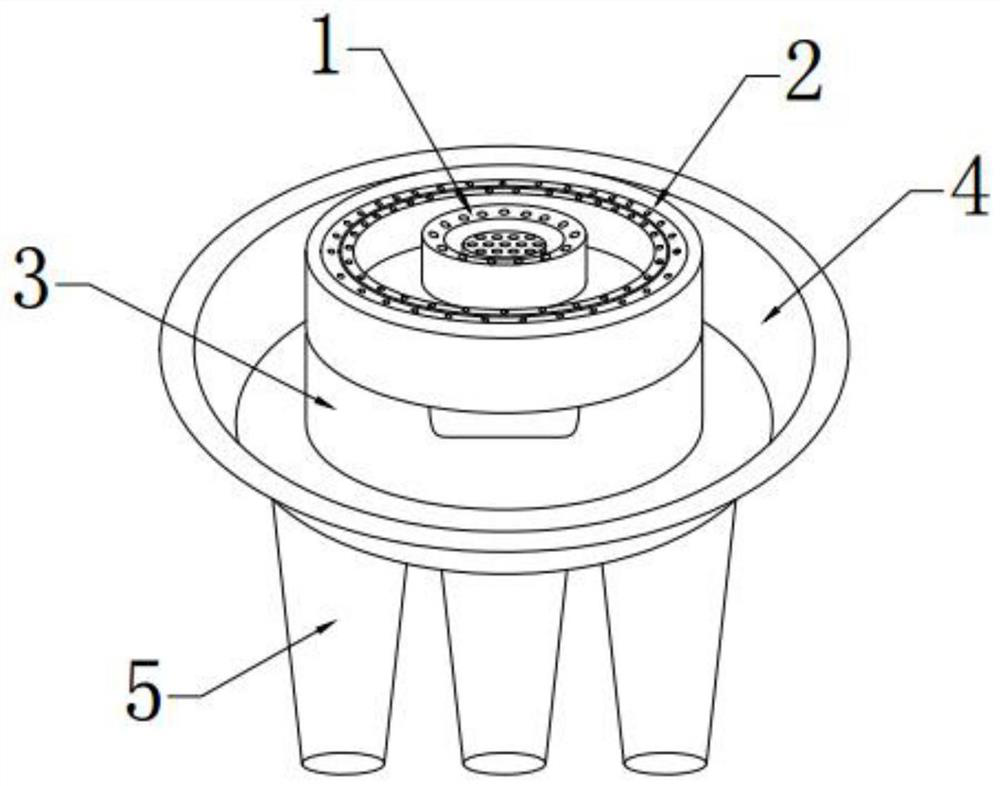

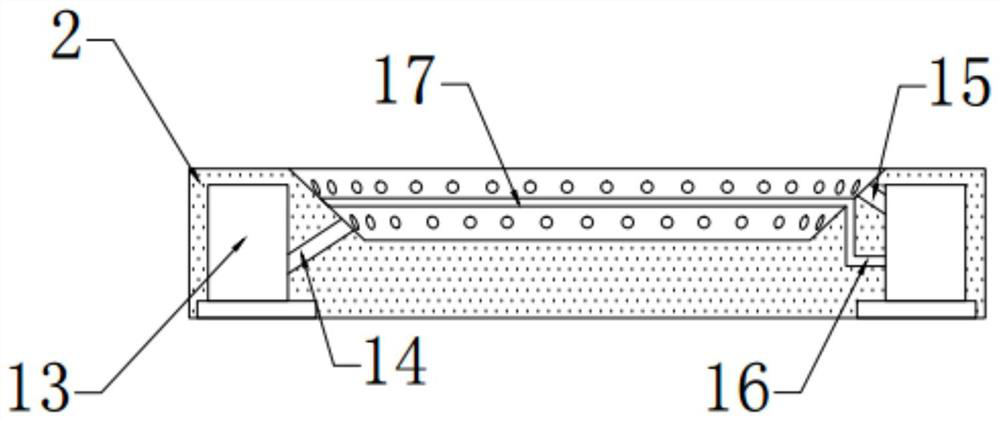

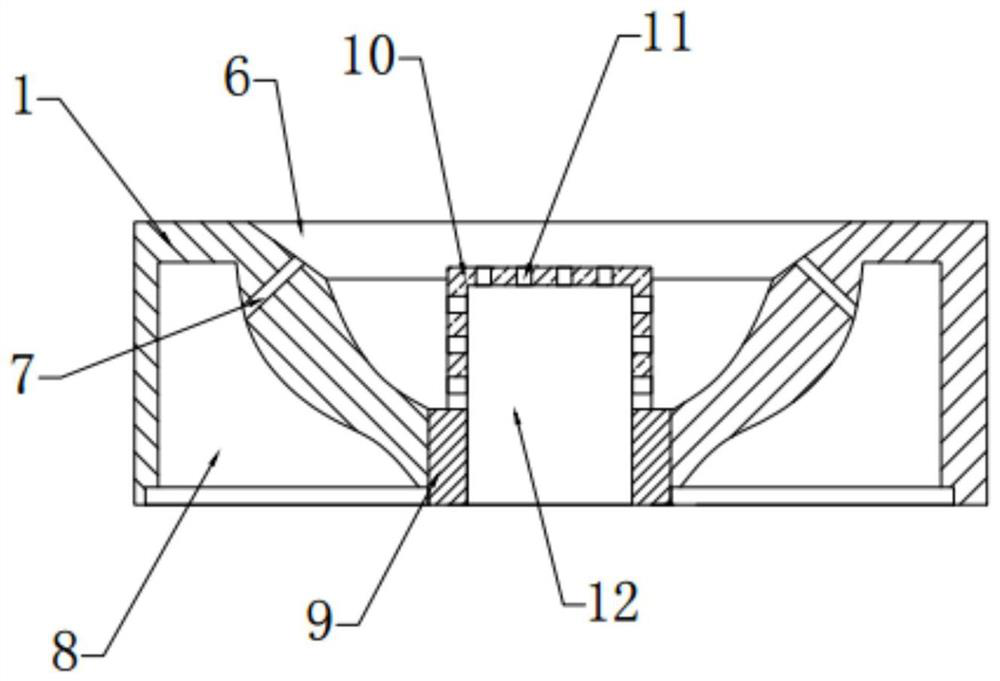

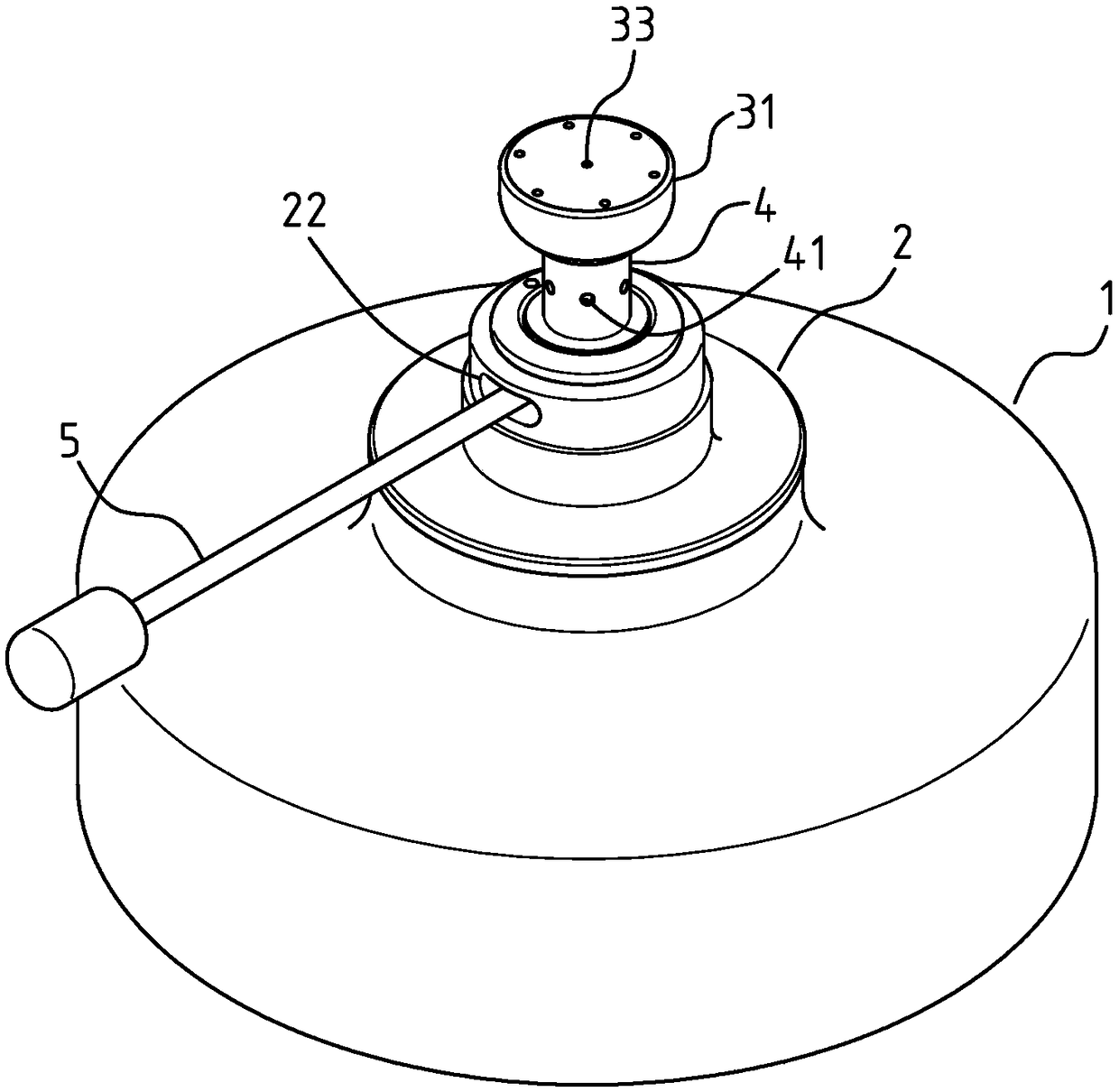

Quincunx fire sealing cover

InactiveCN101561151AEnergy savingSave materialDomestic stoves or rangesLighting and heating apparatusQuincunxEngineering

The invention discloses a quincunx fire sealing cover which belongs to the fire sealing cover. The quincunx fire sealing cover comprises a base seat and an upper cover, the upper cover (2) is connected to the base seat (1) by screws (3), quincunx upper cover fire outlet holes (4) are distributed in the upper cover (2), quincunx base seat fire outlet holes (5) are distributed in the base seat (1), and the upper cover fire outlet holes (4) correspond to the base seat fire outlet holes (5), the holes can be coincident or staggered to regulate the size of the fire outlet holes, thus regulating the firepower. The quincunx fire sealing cover has the advantages of saving energy and material, light weight and smooth and elegant appearance, which is suitable for coal burning furnaces and oil burning furnaces.

Owner:贵阳乌当长宏铸造厂

Multifunctional firewood saving stove

InactiveCN103047684AUsed to adjust the firepowerAdjust the amount of smokeDomestic stoves or rangesLighting and heating apparatusFirewoodBiochemical engineering

The invention provides a multifunctional firewood saving stove which mainly comprises a stove body, a stove panel, stove doors, a stove grate and a chimney, wherein the stove panel is arranged on the upper surface of the stove body, the stove doors are arranged on the lateral surfaces of the stove body, the stove grate is arranged in a hearth of the stove body, and the chimney is arranged above one side of the stove body and is connected with the earth of the stove body. The multifunctional firewood saving stove is characterized in that the stove doors are arranged on two or more than two lateral surfaces of the stove body and are detachable, so that multidirectional firewood charging and warming are facilitated. The multifunctional firewood saving stove has the advantages of facilitating multidirectional firewood charging and warming, reducing firepower fleeing into the chimney, being capable of serving as a hot pot table after being provided with a table top board, facilitating stove ash cleaning and being capable of adjusting the firepower and the smoke discharge amount.

Owner:周勇

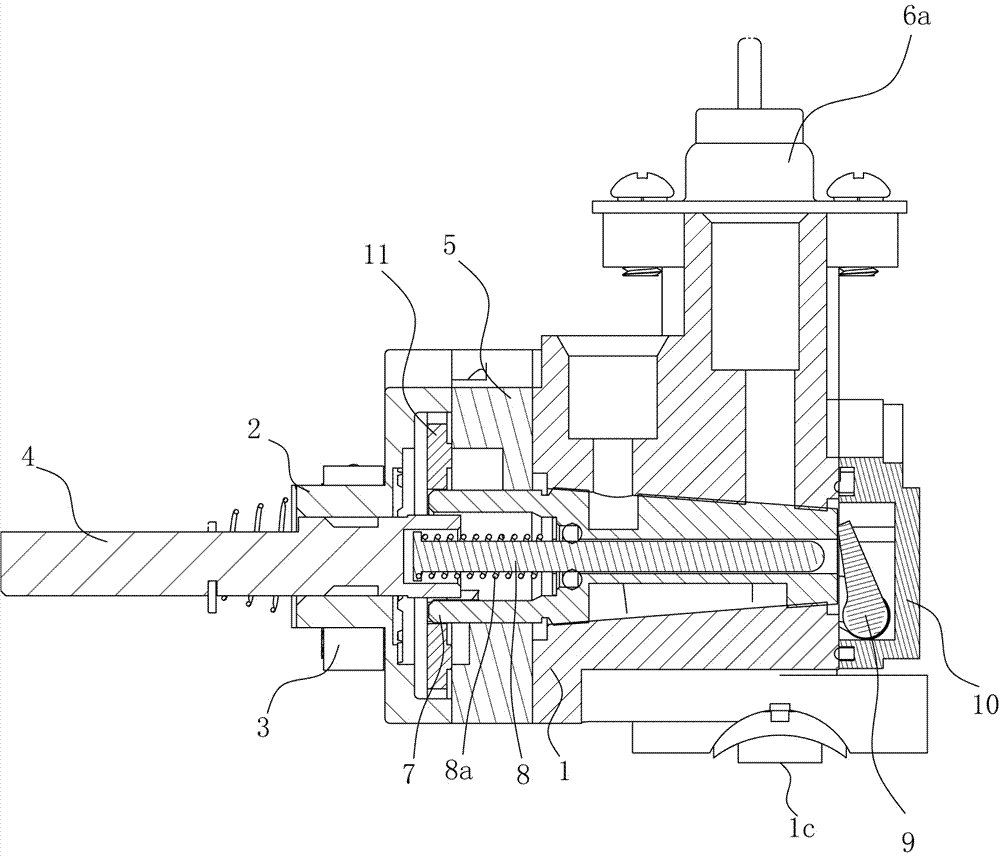

Gas valve of stove burner

ActiveCN104110504AAdjust firepowerPrecise adjustment of air intakeOperating means/releasing devices for valvesSlide valveCombustorHermetic seal

A gas valve of a stove burner comprises a valve body, a valve element, a vale rod, a pressure spring, a fine tuning pin and an electromagnetic valve. The valve body comprises a gas inlet cavity, a gas outlet and a gas guide cavity. The wall plate of the adjacent ends of the gas inlet cavity and the gas outlet is a valve element seat. The valve element seat is provided with a first gas guide passage communicated with the gas guide cavity. The gas guide cavity is communicated with the gas outlet through a second gas guide passage. The fine tuning pin is screwed to the gas guide cavity. The circular valve element is provided with a gas guide hole. The valve element and the valve element seat are fitted and in hermetic seal. The valve rod is fixedly connected with valve element. The end wall plate, opposite to the valve element seat, of the gas inlet cavity is provided with a valve rod passage. The valve rod and the valve rod passage are rotatably matched and in hermitic seal. One end of the pressure spring is matched with the valve element, and the other end thereof is matched with the end wall plate of the gas inlet cavity. An electromagnetic valve seat is communicated with the gas inlet cavity. By the structure, when the valve element rotates, the gas guide hole of the valve element coincides with the first gas guide passage to precisely adjust gas inlet amount so as to adjust the fire of the burner, and use convenience is achieved.

Owner:湖州市双林工业园区开发有限公司

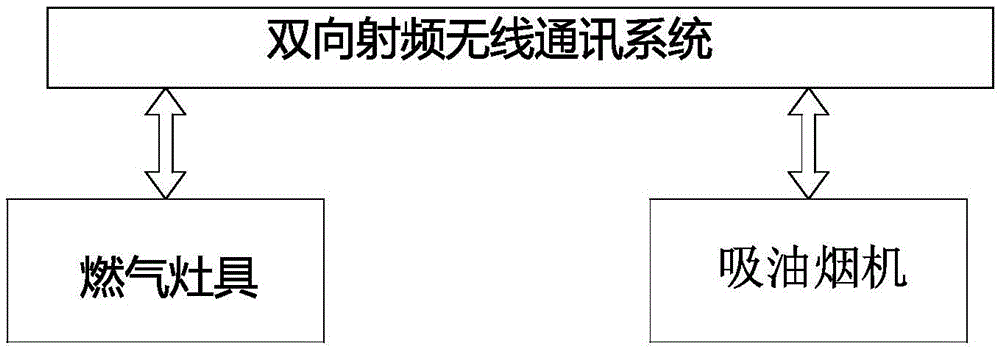

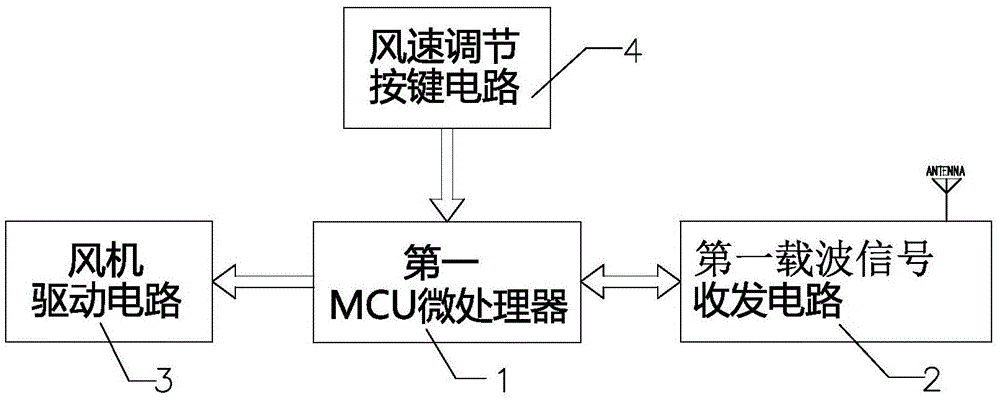

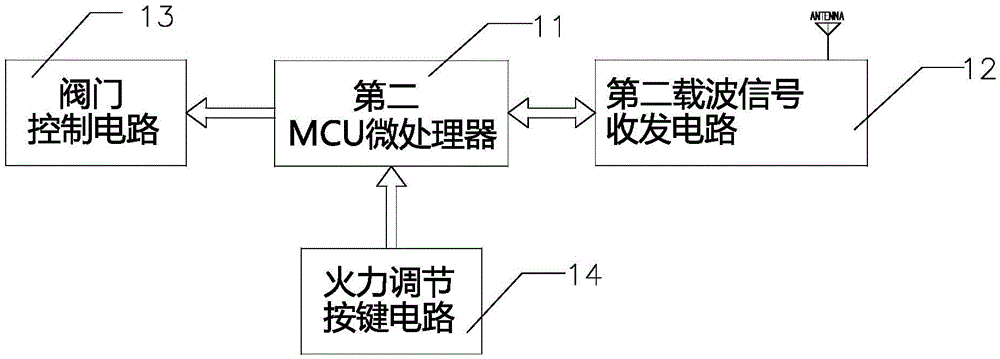

A smoke stove combination with a two-way radio frequency wireless communication system

ActiveCN104296185BIntelligentEnable two-way communicationDomestic stoves or rangesLighting and heating apparatusSmoke compositionRadio frequency

The invention relates to the field of intelligent cooking utensils and particularly relates to a smoke stove combination with a two-way radio frequency wireless communication system. The smoke stove combination comprises a gas stove, a range hood and the two-way radio frequency wireless communication system for two-way communication between the gas stove and the range hood, wherein the two-way radio frequency wireless communication system comprises a gas stove RF signal transceiving control unit arranged in the gas stove and a range hood RF signal transceiving control unit arranged in the range hood; the range hood responds to corresponding wind force aiming at different firepower of the gas stove and similarly responds to the corresponding firepower according to the different wind force of the range hood; and on the basis of realizing intelligentization of equipment in a kitchen, the smoke stove combination also saves energy and is safe and convenient.

Owner:ZHEJIANG SHUAIKANG ELECTRIC

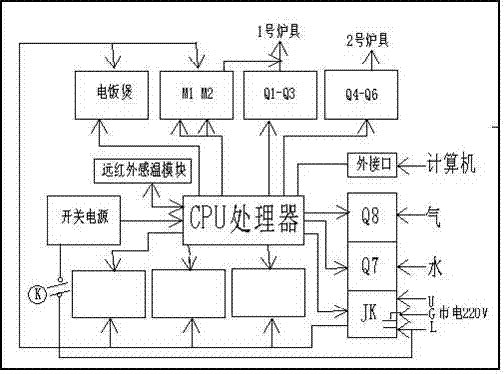

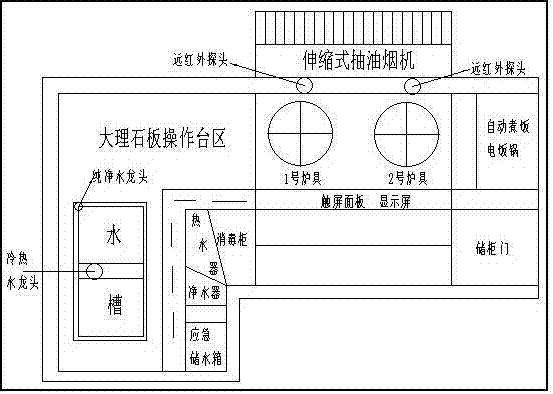

Multifunctional intelligent integrated cooker

PendingCN106871167ASolve problemsThe autostart function hasDomestic stoves or rangesLighting and heating apparatusPotable waterControl engineering

The invention relates to a multifunctional intelligent integrated cooker. The multifunctional intelligent integrated cooker has remote-control automatic rice washing, rice cooking and heat preservation functions, a double-cooker touch screen ignition and firepower magnitude adjusting function, an automatic cooking fume pumping and exhausting, oxygen increasing, combustion supporting and emission reduction function, an automatic tableware disinfection function, an emergency drinking water automatic storage function, a water-electricity-gas one-key opening and closing function, and a remote reservation control function. According to the multifunctional intelligent integrated cooker, the practical functions are integrated, the advantages of being beautiful, practical, economical, safe, convenient to use and the like are achieved, the situation that a person needs to buy electrical appliances with various functions, thus, money wasting and energy consumption are caused, and a lot of spaces are occupied is avoided, and the person does not need to worry about the situation that serious potential safety hazards occur due to the fact that the person goes out for a long time and forgets to close water, electricity and gas switches.

Owner:眉山市政鑫科技有限公司

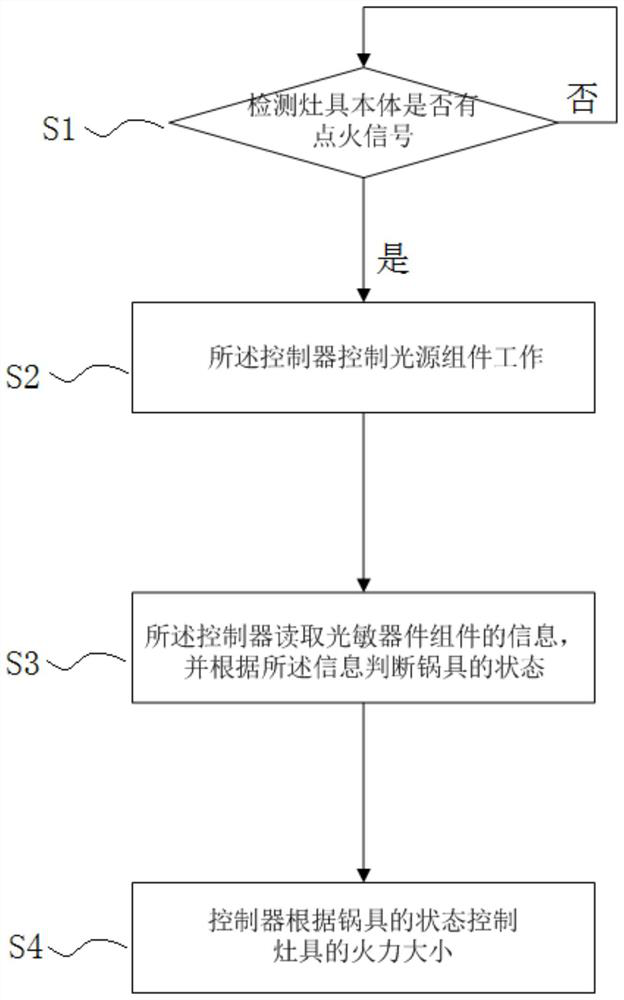

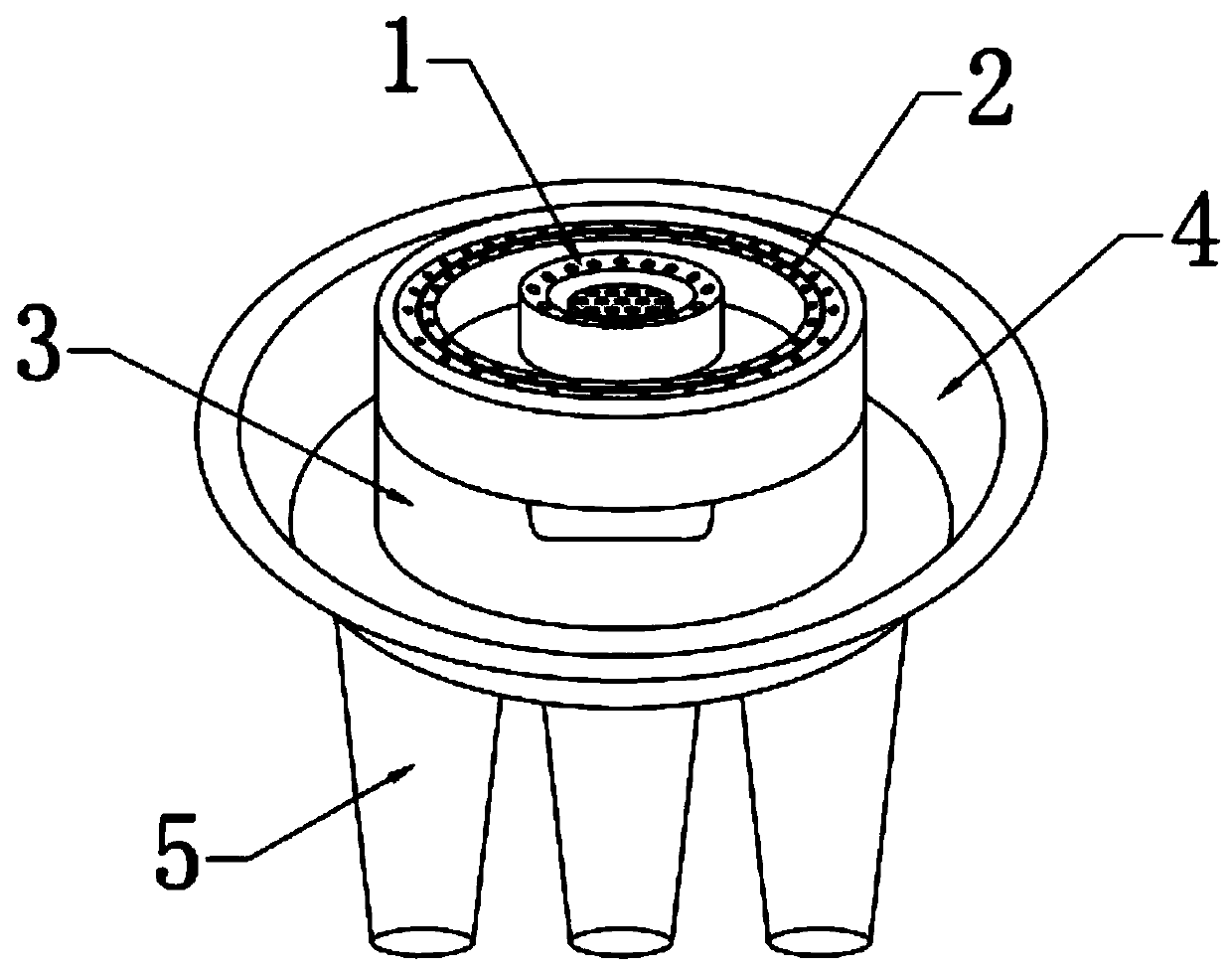

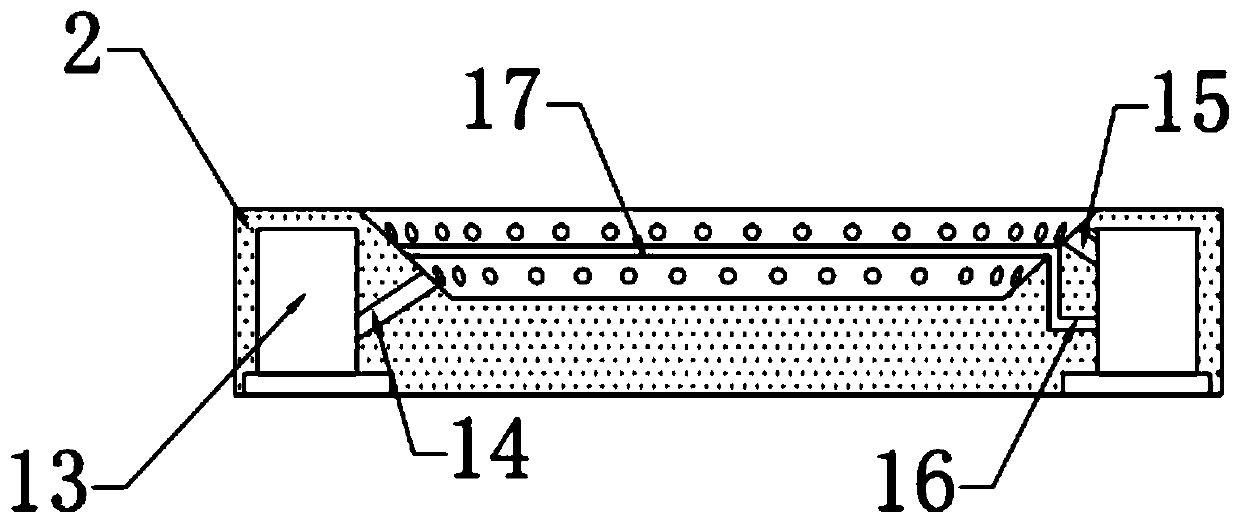

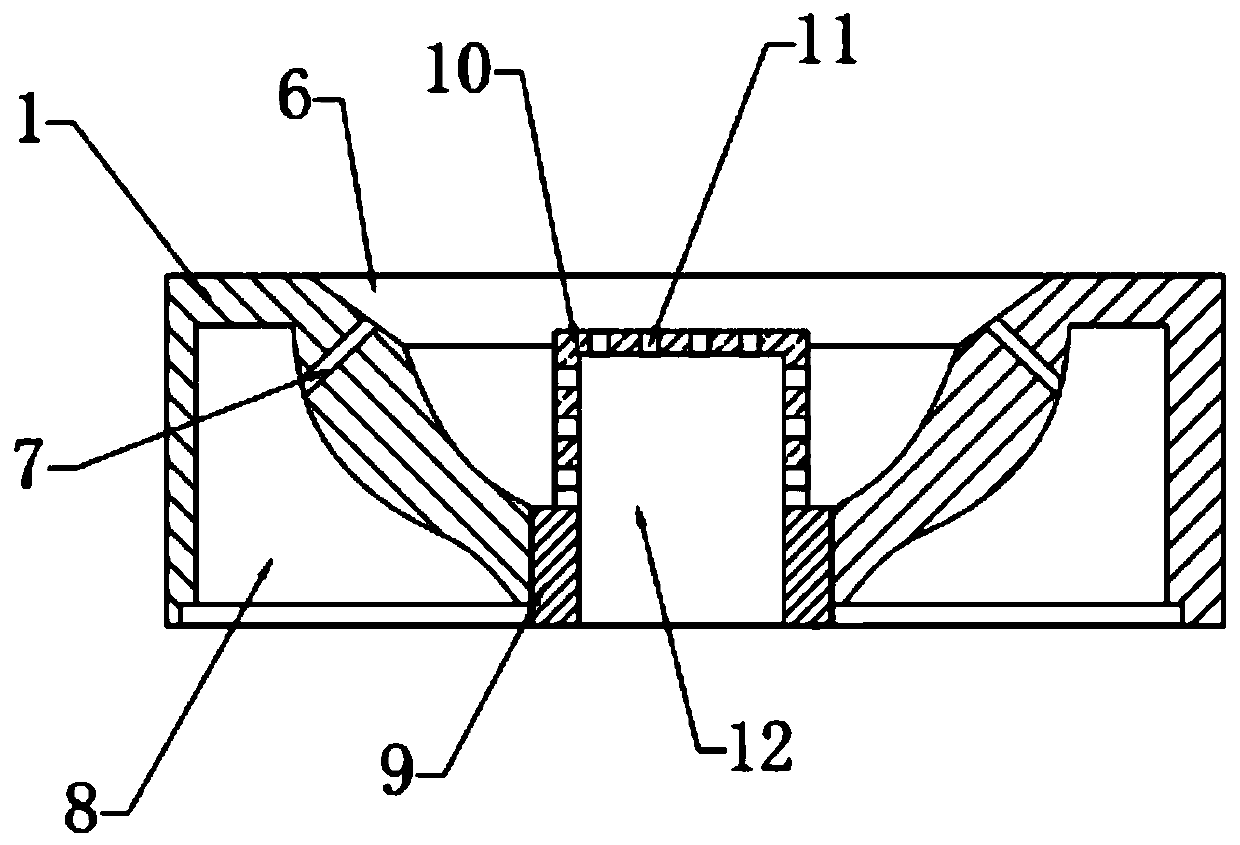

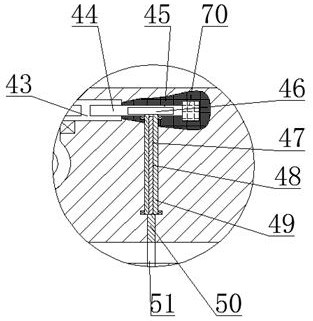

Pot state detection device for cooker and detection method

InactiveCN111853863AAdjust firepowerAvoid Physical Structural FatigueDomestic stoves or rangesLighting and heating apparatusEngineeringCooker

The invention discloses a pot state detection device for a cooker and a detection method. The detection device includes a controller, a telescopic assembly, a light source assembly, a photosensitive device assembly and a cooker body. The light source assembly is fixed on the telescopic assembly and moves upwards and downwards along with the telescopic assembly. The photosensitive device assembly senses the light of the light source assembly, the on-off of the photosensitive device assembly is controlled through the light, and the controller and the cooker body are connected to control the firepower of the cooker according to the on-off of the photosensitive device assembly. The state of a pot is determined through the interaction between the light source assembly and the photosensitive device assembly, since the photosensitive device assembly is not physically connected to the telescopic assembly, the state of the pot can be judged, compared with a traditional method of detecting the state of the pot through temperature, the sensitivity is higher, and physical structural fatigue caused by long-term use of traditional physical devices such as springs, compression springs and micro switches is avoided.

Owner:VATTI CORP LTD

Three-ring fire burner and gas stove

ActiveCN110186042AStrong firepowerIncrease the areaDomestic stoves or rangesGaseous fuel burnerHeat lossesEngineering

The invention relates to the technical field of household gas stoves, in particular to a three-ring fire burner and a gas stove. The three-ring fire burner comprises a gas dividing base, wherein an outer-ring fire cover and an inner-ring fire cover are sequentially arranged on the top of the gas dividing base from outside to inside; a plurality of fire holes are formed in the the inner side of theouter-ring fire cover; a fire groove is formed among the fire holes; the gas outgoing directions of the fire holes and the fire groove point to a central area of the burner; a water receiving tray isarranged at the bottom of the gas dividing base; and an injection tube is arranged at the bottom of the water receiving tray. According to the three-ring fire burner and the gas stove disclosed by the invention, through arrangement of the fire holes and the fire groove pointing to the central area of the burner, heat-gathering burning can be carried out, so that the heating efficiency is improved, and the heat loss is reduced; through arrangement of a second fire outlet hole and a third fire outlet hole, the area of fire outlet holes can be increased; and through arrangement of partitioning plates, a structure of the inner-ring fire cover is more compact, and the size of the top part of the burner can be reduced, so that the heat exchanging time between a pot bottom and flame is extended,the heat exchanging area is increased, the heat efficiency of the gas stove is improved, and the cost of the burner is reduced.

Owner:深圳市唐家厨房设备有限公司

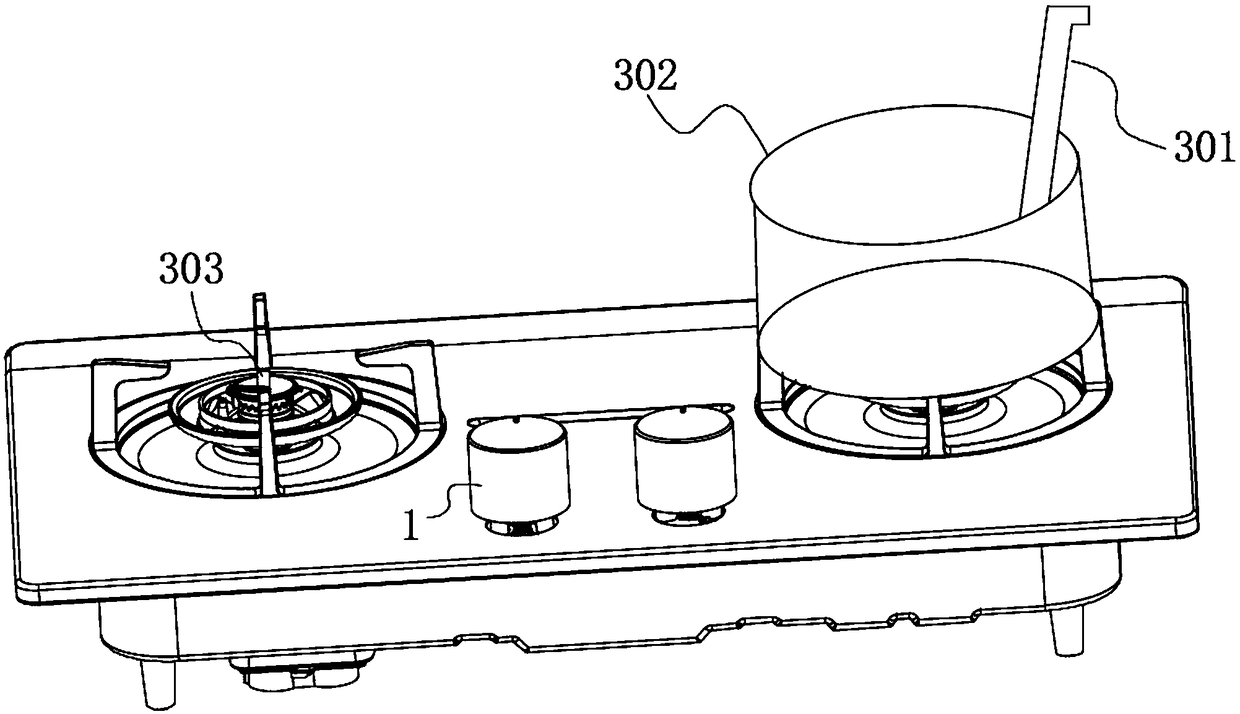

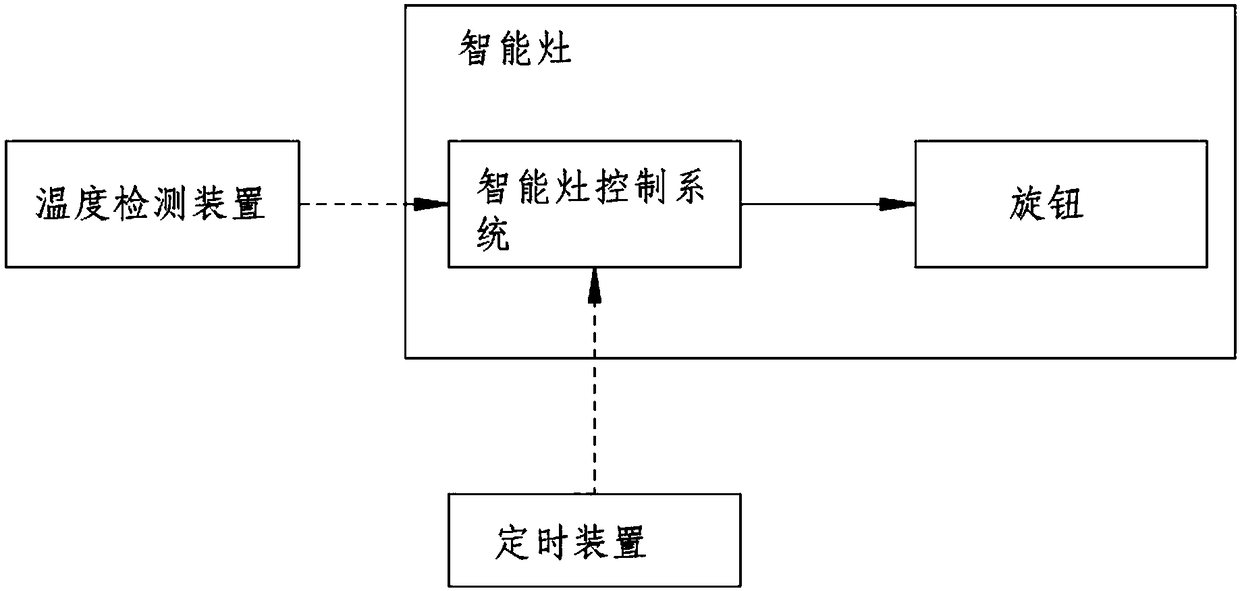

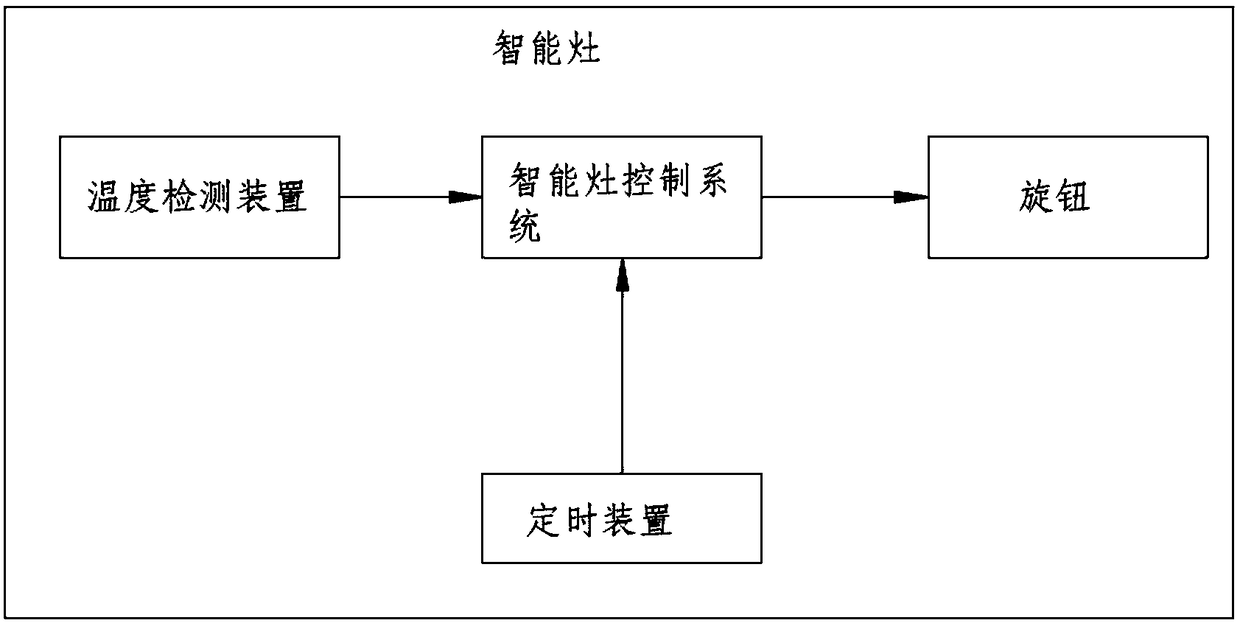

Intelligent kitchen range

PendingCN108426274AAdjust firepowerControlled fireDomestic stoves or rangesLighting and heating apparatusAuto regulationControl system

The invention creatively relates to the technical field of kitchen ranges, in particular to an intelligent kitchen range. The intelligent kitchen range is provided with a temperature detection device,a timing device and a knob having the automatic regulating function, the temperature detection device and the timing device can be integrated on the intelligent kitchen range, and can also be independent from the intelligent kitchen range, the temperature detection device, the timing device and the knob are connected with a control system, the control system controls the regulation of the knob according to the corresponding temperature signal and the timing signal, and then the fire power of the intelligent kitchen range is regulated.

Owner:VATTI CORP LTD

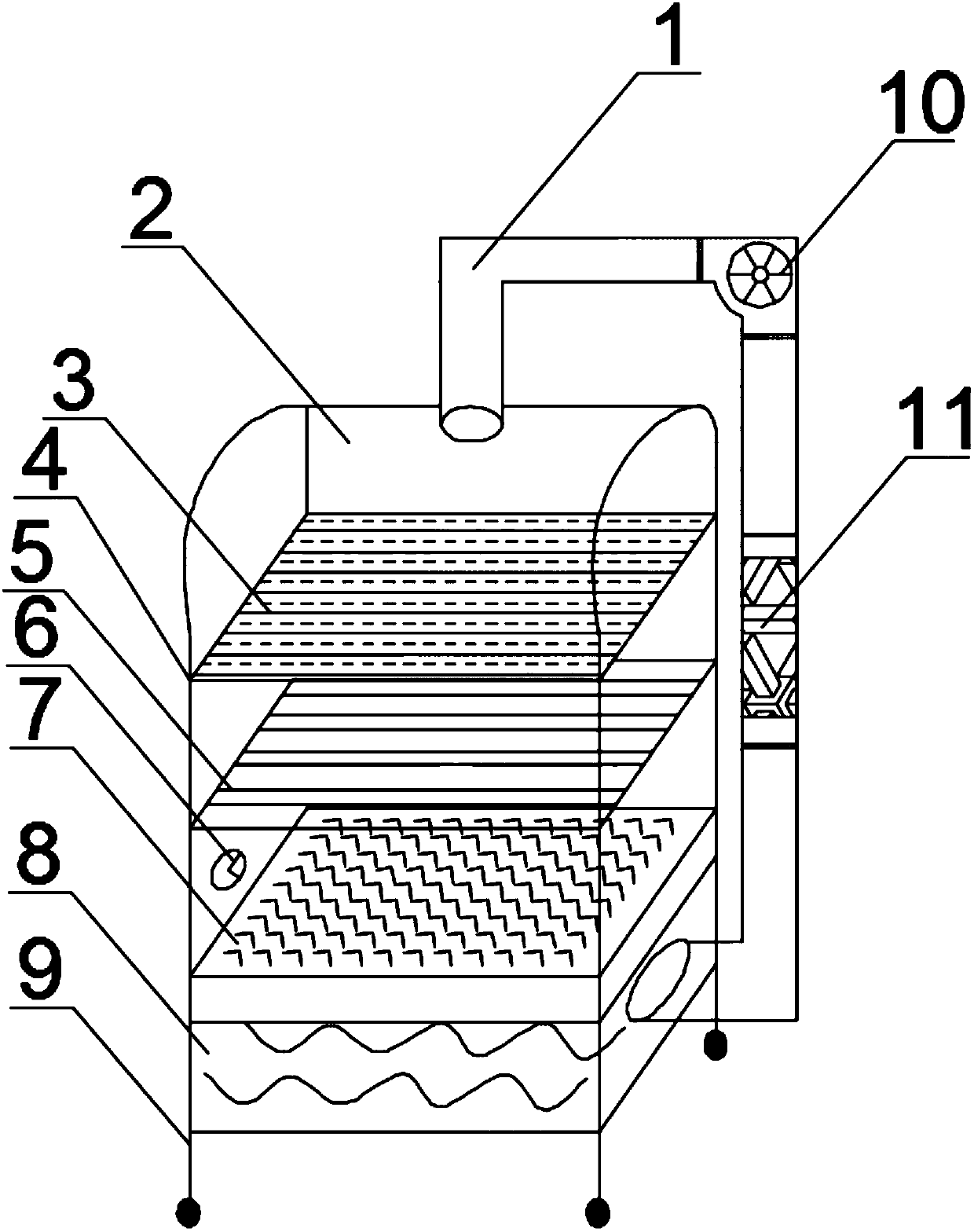

Indoor barbecuing device

InactiveCN107713796AReduce direct pollutionSimple structureRoasters/grillsActivated carbonEngineering

The invention discloses an indoor barbecue device, which relates to the field of barbecue devices and is used to solve the problems that the existing indoor barbecue devices cannot handle oil fume, or the problem of high cost of oil fume treatment and inconvenient disassembly. Cover and smoke pipe, the barbecue device also includes a water tank, support rods, oil filter, exhaust fan and activated carbon, the water tank is located below the charcoal tank, and the support rod is threaded on the smoke collection hood, grilling net, charcoal tank and the four corners of the water tank, the oil filter is arranged at the lower part of the smoke collection hood, one end of the exhaust pipe is connected to the smoke collection hood, and the other end is connected to the water tank, and an exhaust fan is arranged in the middle of the smoke pipe. Activated carbon is arranged inside the exhaust pipe. The invention has the advantages of simple structure, little pollution, convenient disassembly and strong applicability.

Owner:弘毅天承知识产权股份有限公司

A kind of low volatile briquette coal environmental protection and energy-saving furnace

ActiveCN109539316BNovel structureImprove combustion effectDomestic stoves or rangesCombustion processFurnace temperatureAir heater

The invention discloses a low-volatile briquette coal environment-friendly and energy-saving furnace. A vibration fire grate, an induced air device, a front furnace wall, a rear furnace wall, a primary air heater, a tail flue, a heat exchange water tank and the like are included. The low-volatile briquette coal environment-friendly and energy-saving furnace has the functions that a forward combustion furnace hearth structure is improved, furnace inner gas disturbance is enhanced, black smoke emission is reduced, a smoke and ash waste heat recycling device is additionally arranged, primary airis preheated, the low-volatile fuel combustion capability is enhanced, and clean and efficient gradient utilization of briquette coal is promoted. In the low-volatile briquette coal environment-friendly and energy-saving furnace, the hearth structure is novel; compared with a traditional forward combustion furnace, the furnace temperature can be increased, the furnace inner gas disturbance is enhanced, the briquette coal combustion effect is enhanced, and the briquette coal burn-off rate is increased; a self-heating secondary air system and a waste heat recycling device are introduced, the combustion efficiency of the furnace is improved, a frequency-adjustable vibration fire grate and a wind-frequency-changeable air supply device are applied, the fire power adjusting capability of the furnace is improved, the furnace is integrally high in adaptability to multiple fuels, and the characteristics of economy and practicability are achieved.

Owner:XI AN JIAOTONG UNIV

A natural gas stove for preventing dry burning

ActiveCN110617501BPrevention of dry burningAdd water in timeDomestic stoves or rangesLighting and heating apparatusThermodynamicsEngineering

The invention relates to the field of natural gas applications, in particular to a natural gas stove for preventing dry burning, which includes a stove body and a first guide chute with an upward opening arranged in the top wall of the stove body, and the top wall of the stove body is fixedly arranged There are support seats symmetrically distributed around the first slide guide groove, and a heat conduction rod is slidably arranged in the first slide guide groove, and a heat conduction rod is arranged between the heat conduction rod and the bottom wall of the first slide guide groove The first spring, a natural gas stove that prevents dry burning provided by the present invention, can effectively prevent dry burning of the natural gas gas stove. Add water to the pot to prevent fire. When the device is in normal use, the firepower can be adjusted, and water can be conveniently added to the pot. This device can only be connected to natural gas when the spark plug is turned on, which is safer.

Owner:汪亚东

A three-ring fire burner and gas stove

ActiveCN110186042BStrong firepowerIncrease the areaDomestic stoves or rangesGaseous fuel burnerEngineeringHeat losses

Owner:深圳市唐家厨房设备有限公司

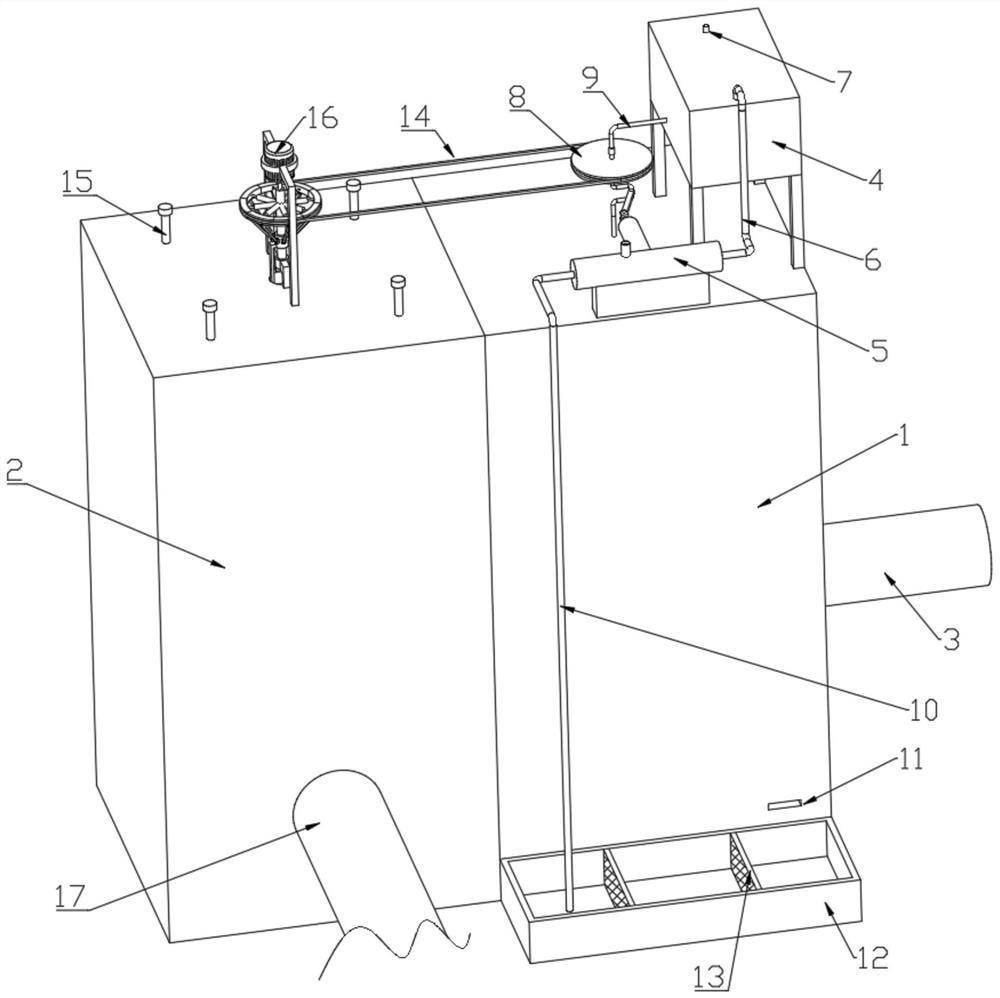

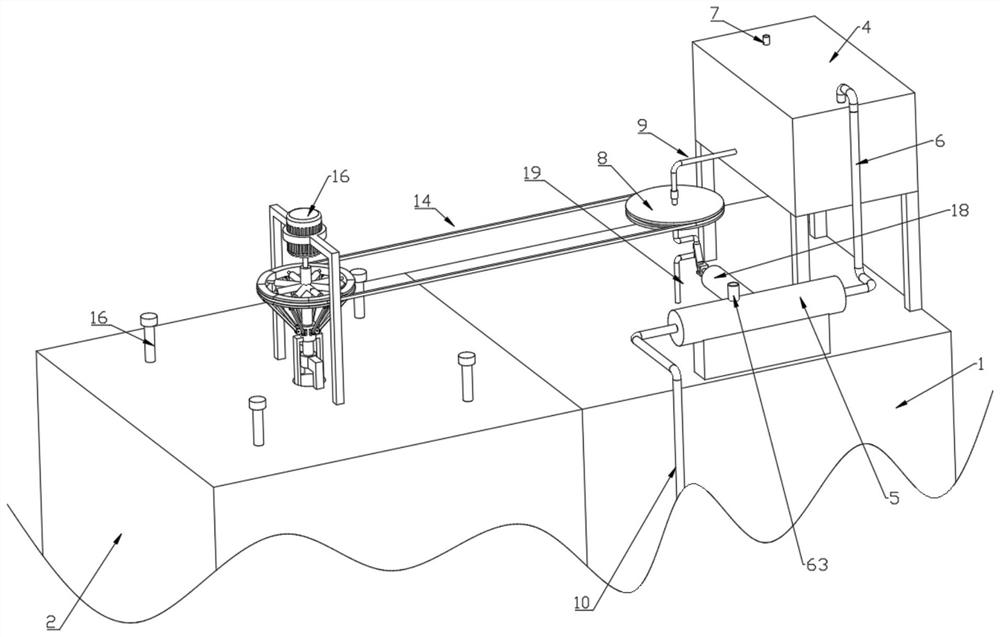

Energy-saving and environment-friendly industrial waste gas combustion treatment device

InactiveCN113685830AAdjust firepowerReal-time adjustment of water replenishment speedHuman health protectionUsing liquid separation agentCombustionElectric machine

The invention discloses an energy-saving and environment-friendly industrial waste gas combustion treatment device. The energy-saving and environment-friendly industrial waste gas combustion treatment device comprises a spraying tower and an incinerator; a spraying driving module is arranged on the incinerator; a combustion cavity is formed in the incinerator; a steam box is arranged at the upper end of the combustion cavity; water is arranged in the steam box; a sliding plate is arranged at the upper end of the steam box; the upper end of a sliding rod penetrates through the upper end of the incinerator; a second spring is arranged on the outer wall of the end, located in the incinerator, of the sliding rod in a sleeving mode; the upper end of a connecting rod is fixedly connected with a sliding sleeve; the upper end of the connecting sleeve is fixedly connected with a motor; an output shaft of the motor is fixedly connected with the upper end of a rotating shaft; a supporting rod is connected to the interior of a sliding cylinder in a limiting and sliding mode; multiple expansion blocks are arranged and form a complete circle; the outer wall of the sliding sleeve is rotationally connected with an ejector rod through a pin shaft; and the upper end of the ejector rod is rotationally connected to the lower surfaces of the expansion blocks through pin shafts. The energy-saving and environment-friendly industrial waste gas combustion treatment device has the advantages that the spraying effect is better, dynamic control of combustion firepower and real-time adjustment of the spraying effect are realized, and energy conservation, environmental protection and high resource utilization rate are achieved.

Owner:李艳程

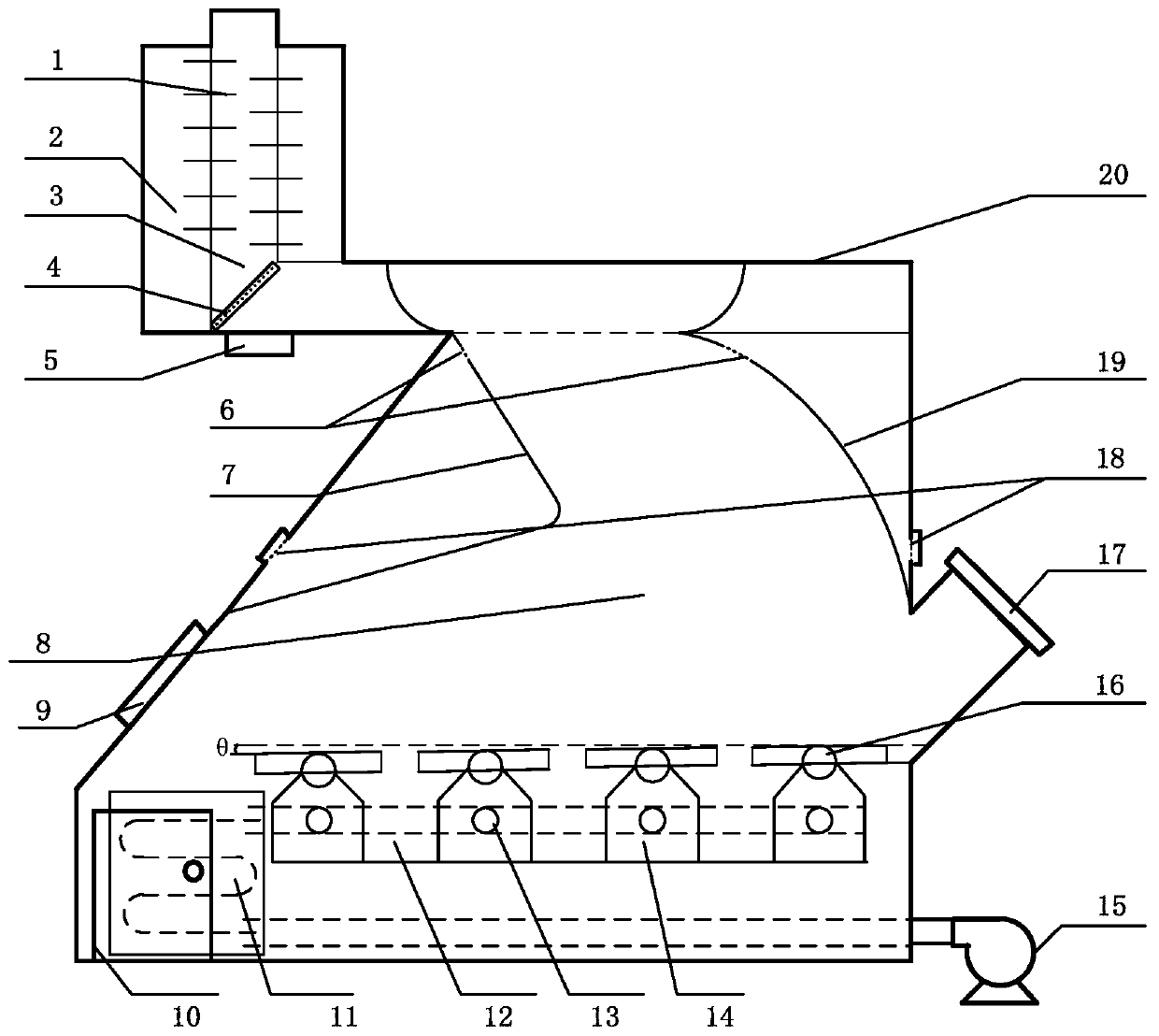

Barbecue oven without soot

PendingCN107485307AReduce volumeReduce weightClimate change adaptationCombustion chamberExhaust fumes

The invention relates to a barbecue oven without soot. The oven comprises a support, combustion furnaces, a heat conduction partition plate and a fuel source, the heat conduction partition plate is horizontally placed on the support, and a combustion chamber is formed in the portion, below the heat conduction partition plate, of the support; the combustion furnaces are located in the combustion chamber, the fuel source is provided with fuel supply pipes which supplied fuel to the combustion furnaces, adjustment valves which adjust the fuel supply rate are arranged on the fuel supply pipes, and air outlets which are communicated with the combustion furnaces and concentratedly discharge waste gas are formed in the support. According to the technical scheme, the barbecue oven without the soot is healthy.

Owner:黄维斌

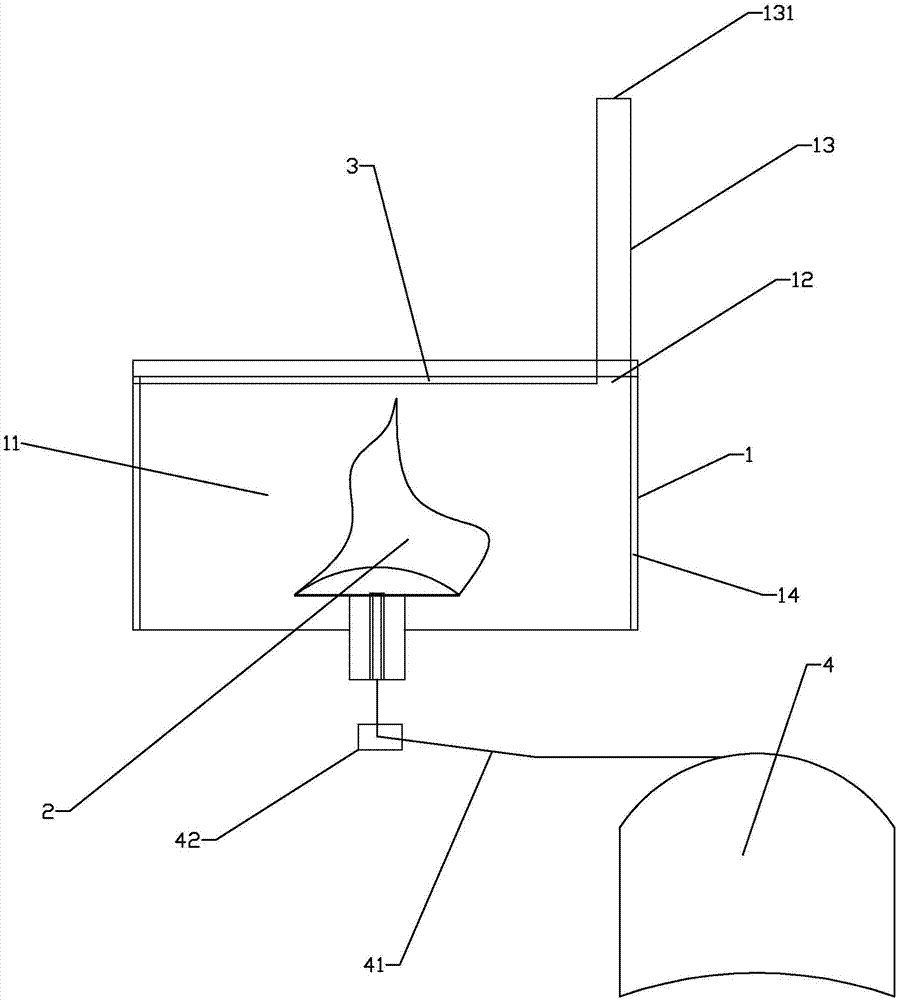

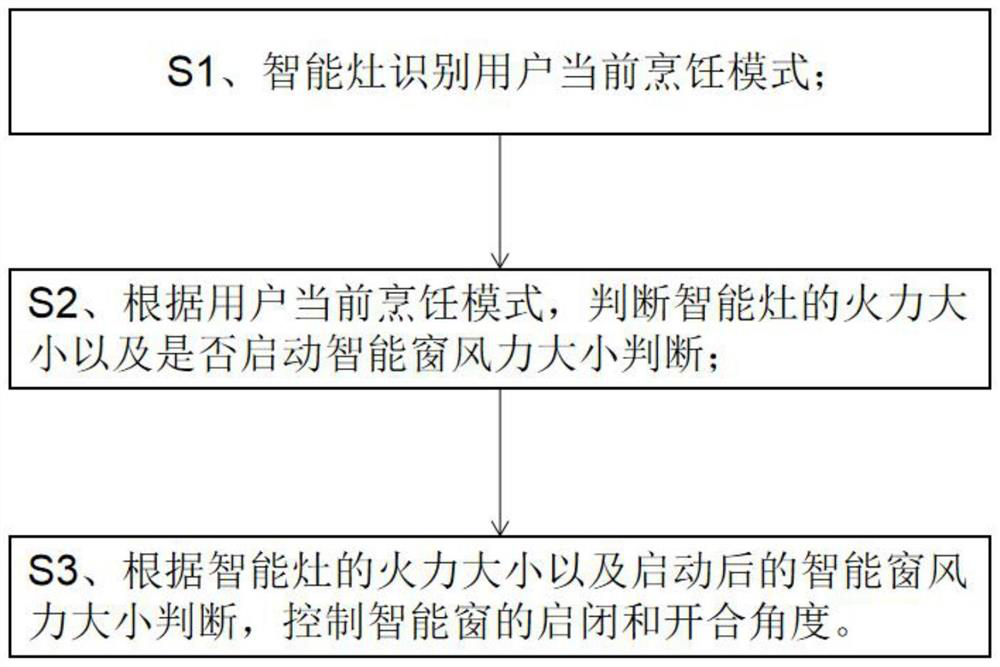

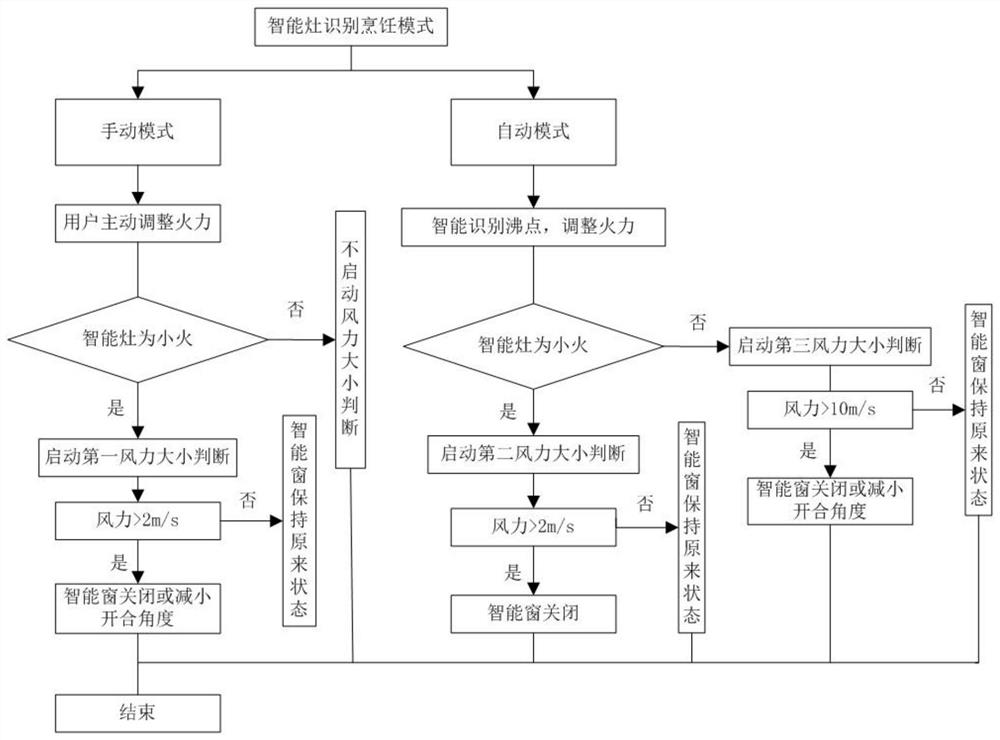

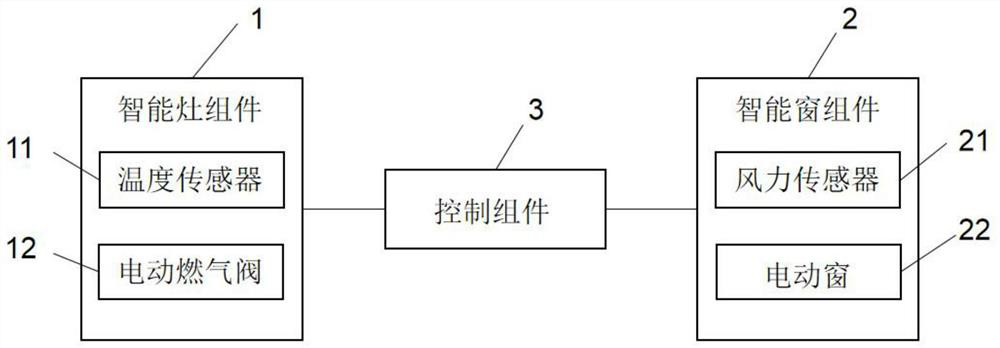

Interconnection method of intelligent stove and intelligent window and system applying same

ActiveCN112013426AAdjust firepowerPrevent the phenomenon of extinguishingDomestic stoves or rangesLighting and heating apparatusControl engineeringWind power

The invention discloses an interconnection method of an intelligent stove and an intelligent window and a system applying same. The interconnection method comprises the following steps that S1, the intelligent stove recognizes a current cooking mode of a user; S2, according to the current cooking mode of the user, the firepower of the intelligent stove and whether the judgement of the intelligentwindow wind power is started or not are judged; and S3, according to the firepower of the intelligent stove and the wind power of the intelligent window, the opening and closing and the opening and closing angle of the intelligent window are controlled. According to the interconnection method of the intelligent stove and the intelligent window, through different cooking modes selected by the user,the firepower of the intelligent stove and whether the judgement of the intelligent window wind power is started or not are judged, and then the opening and closing and the opening and closing angleof the intelligent window are controlled according to the firepower of the intelligent stove and the wind power of the started intelligent window, so that the phenomenon that flames of the stove are extinguished due to an environmental change or fluctuation is prevented, the home experience is improved, and the intelligent control level of a kitchen space is improved.

Owner:VATTI CORP LTD

A portable grill

Owner:杨思慧

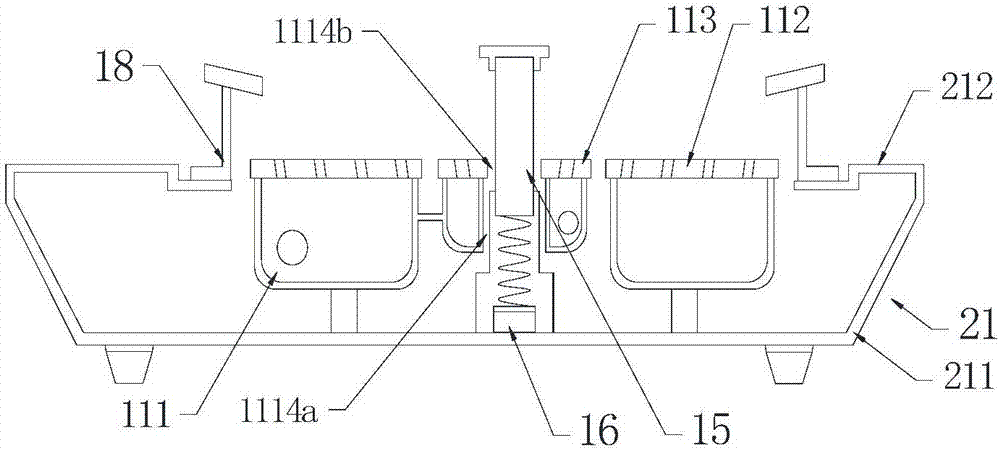

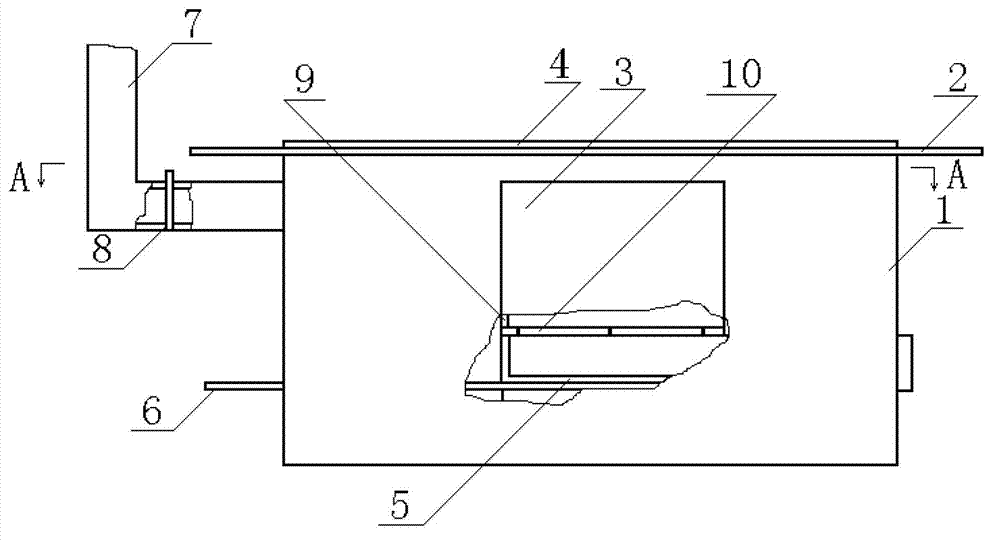

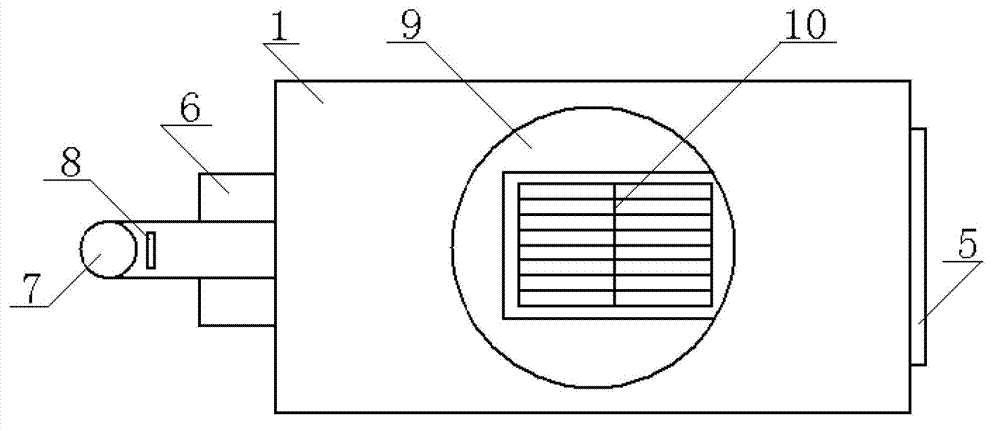

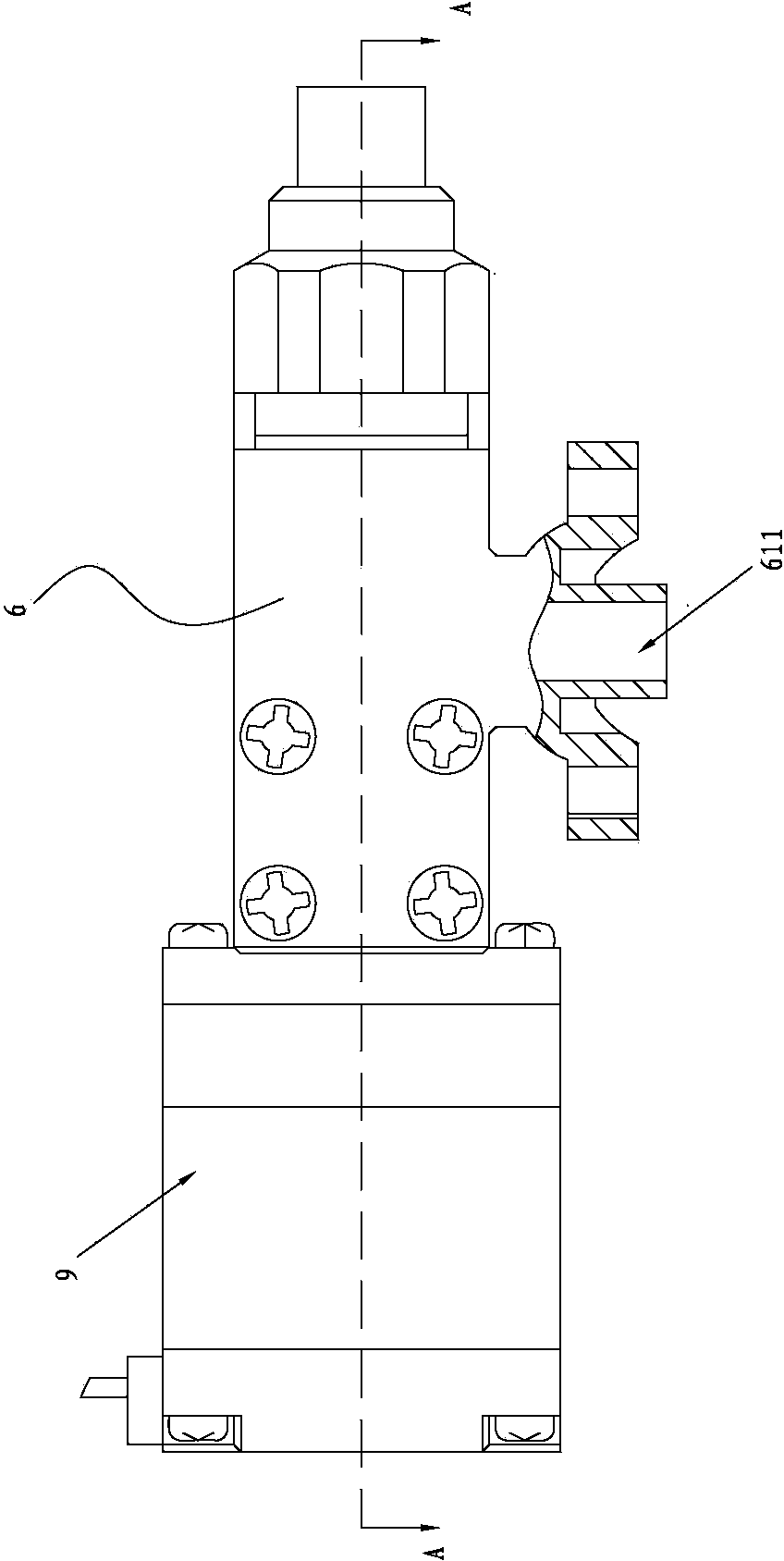

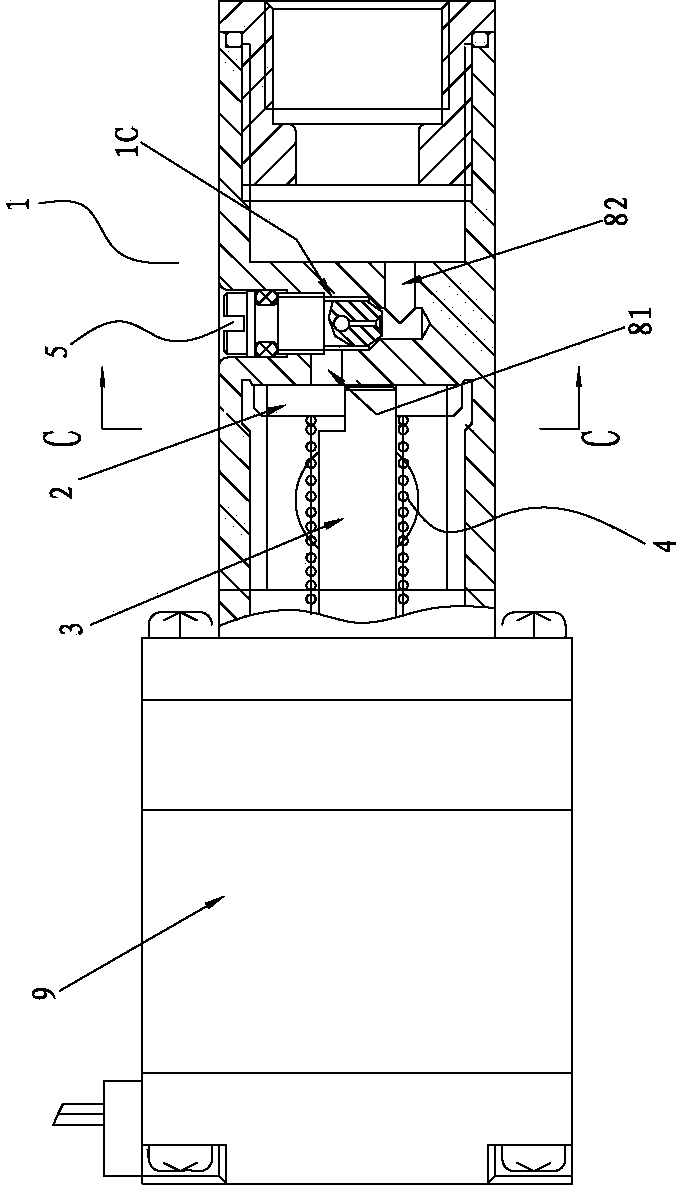

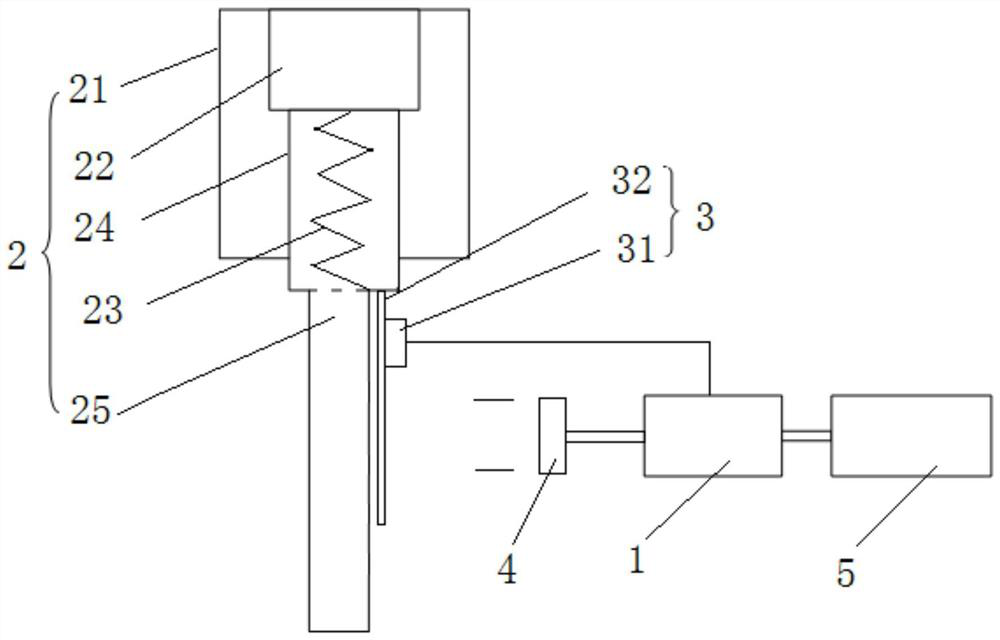

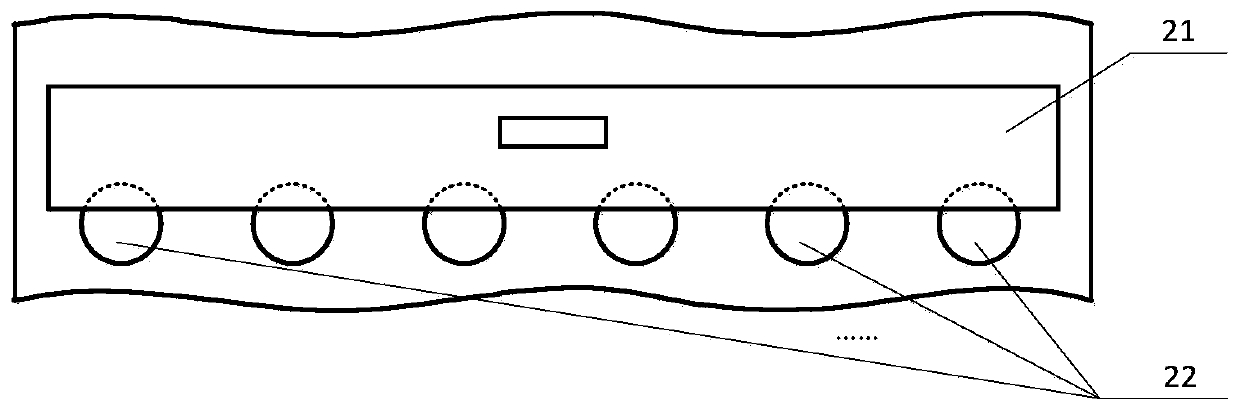

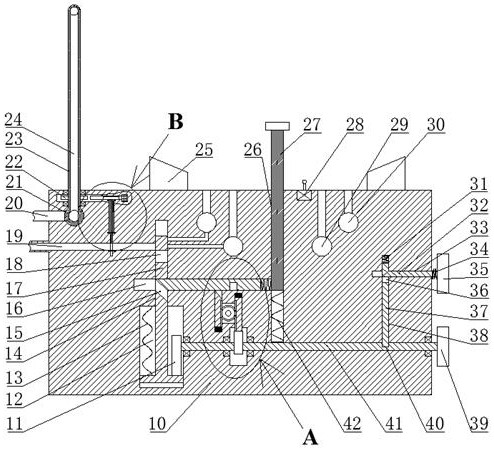

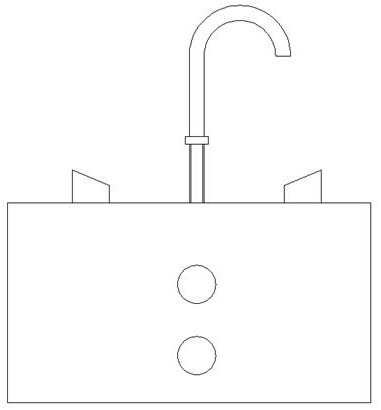

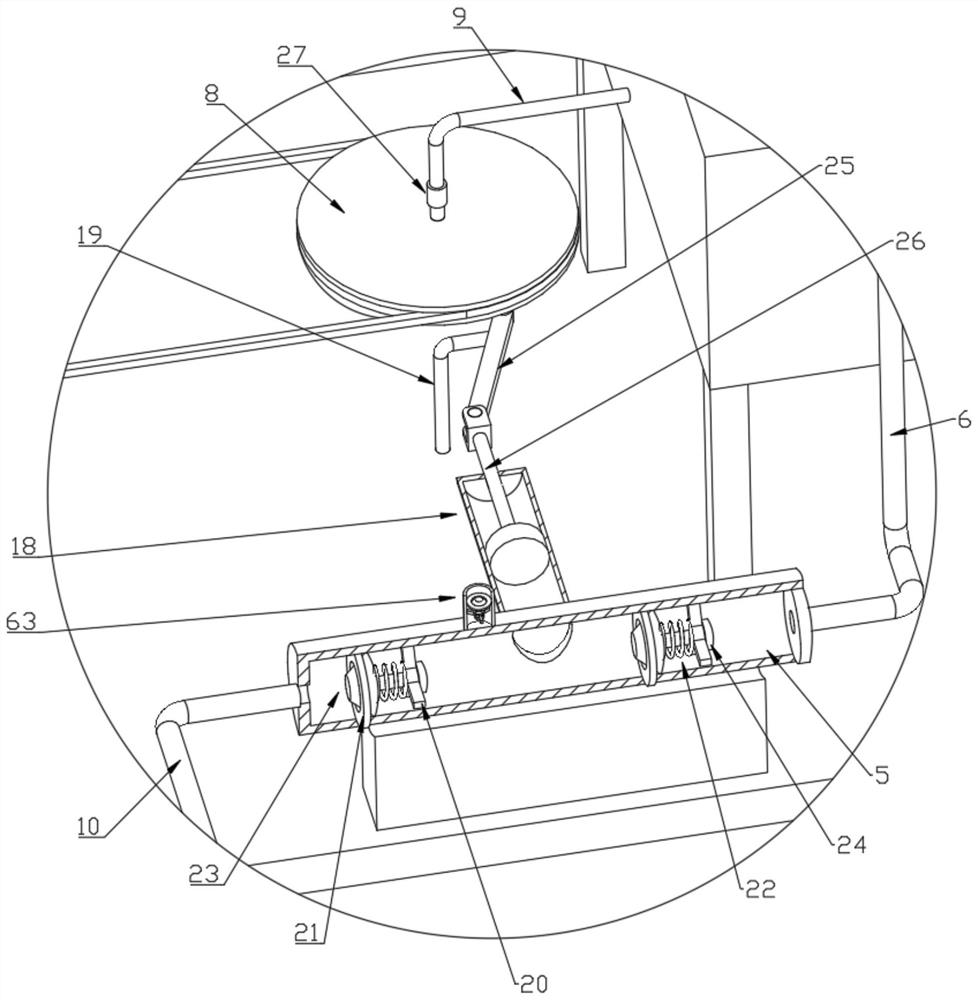

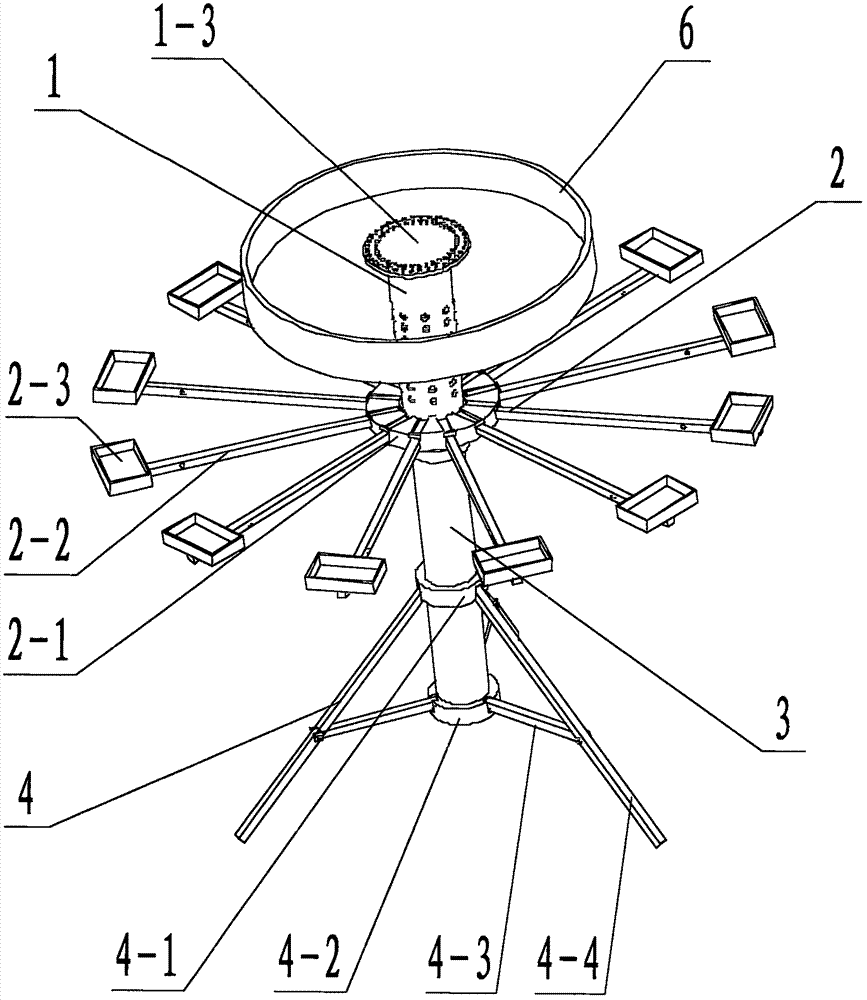

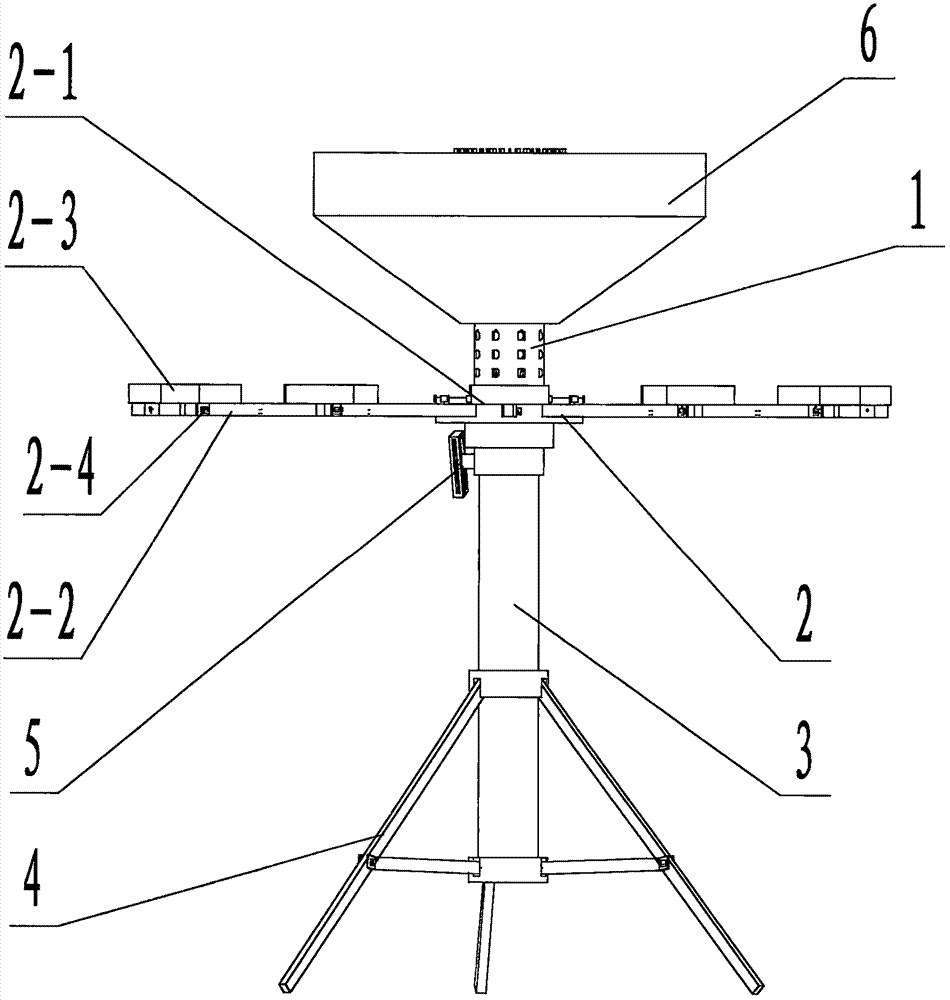

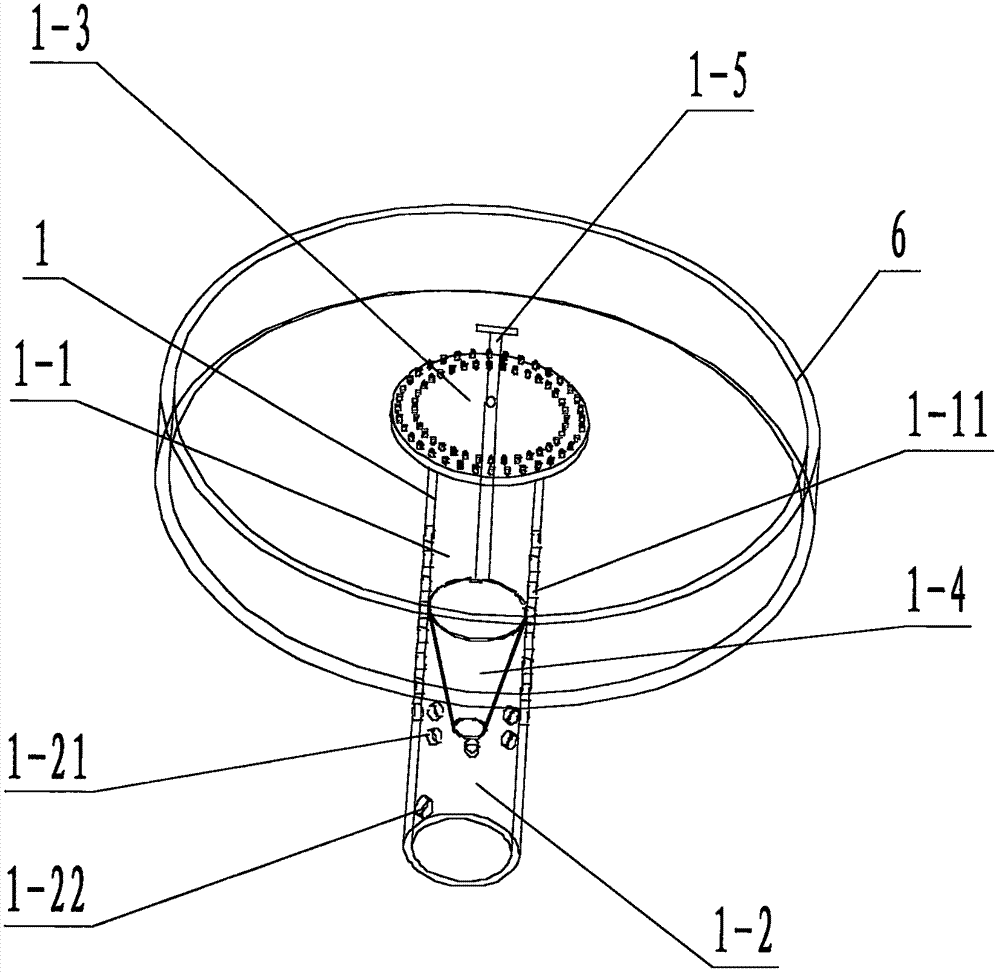

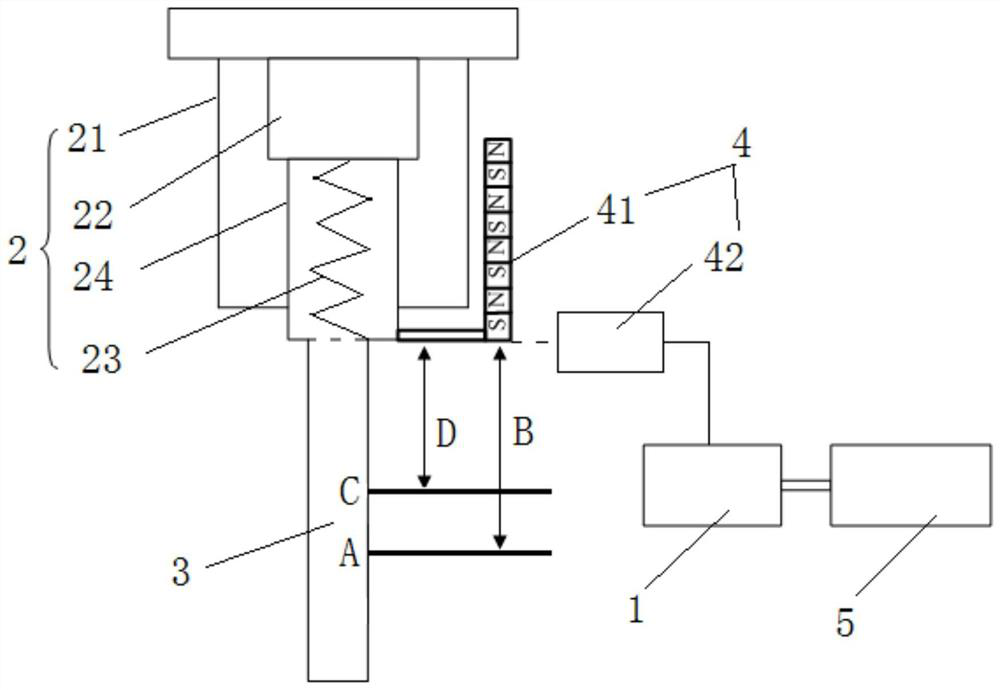

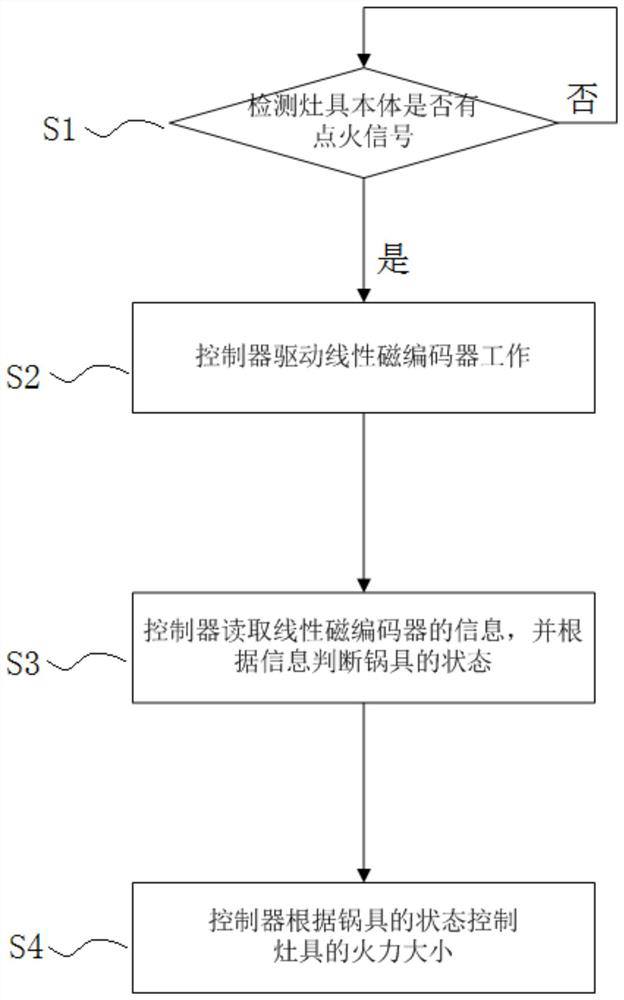

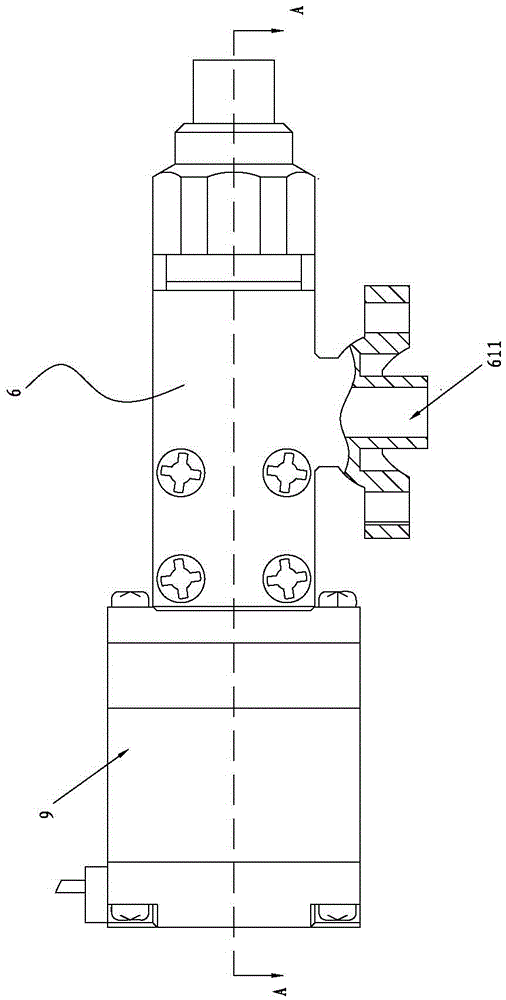

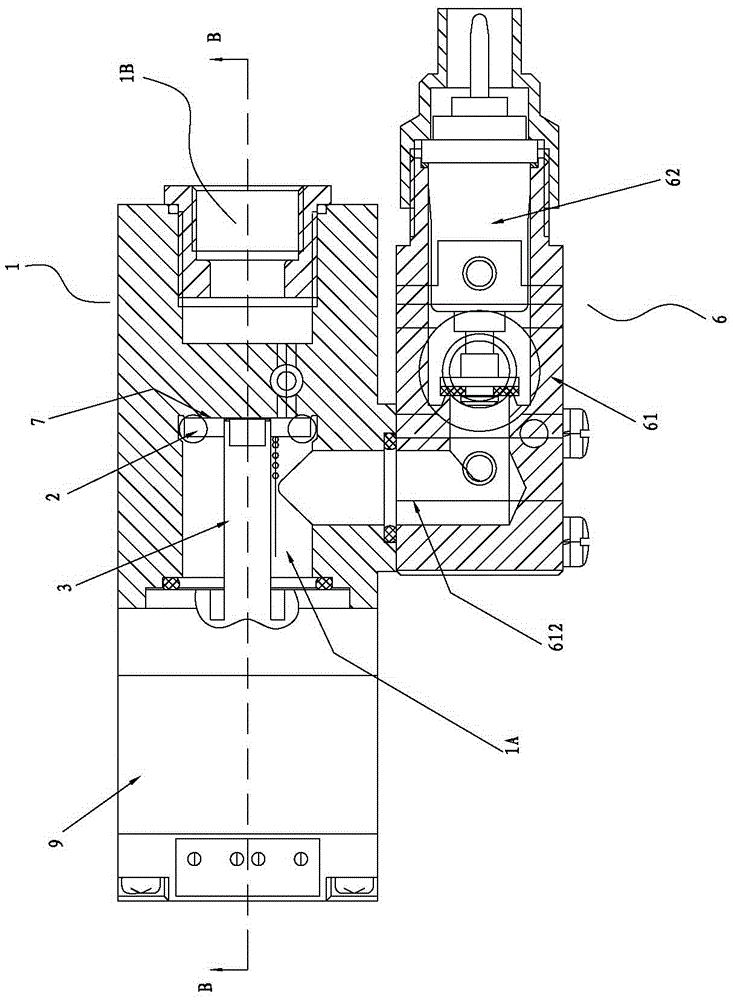

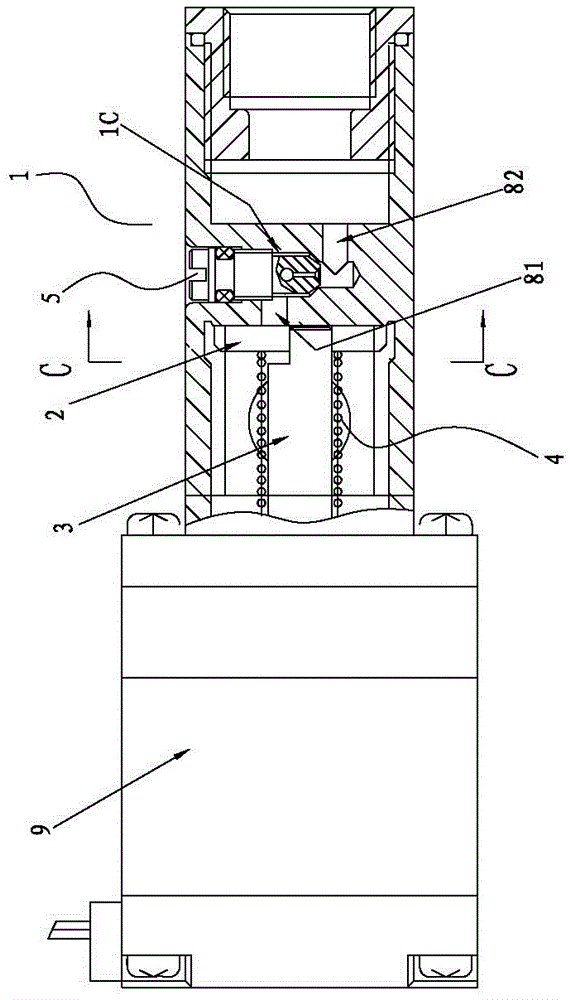

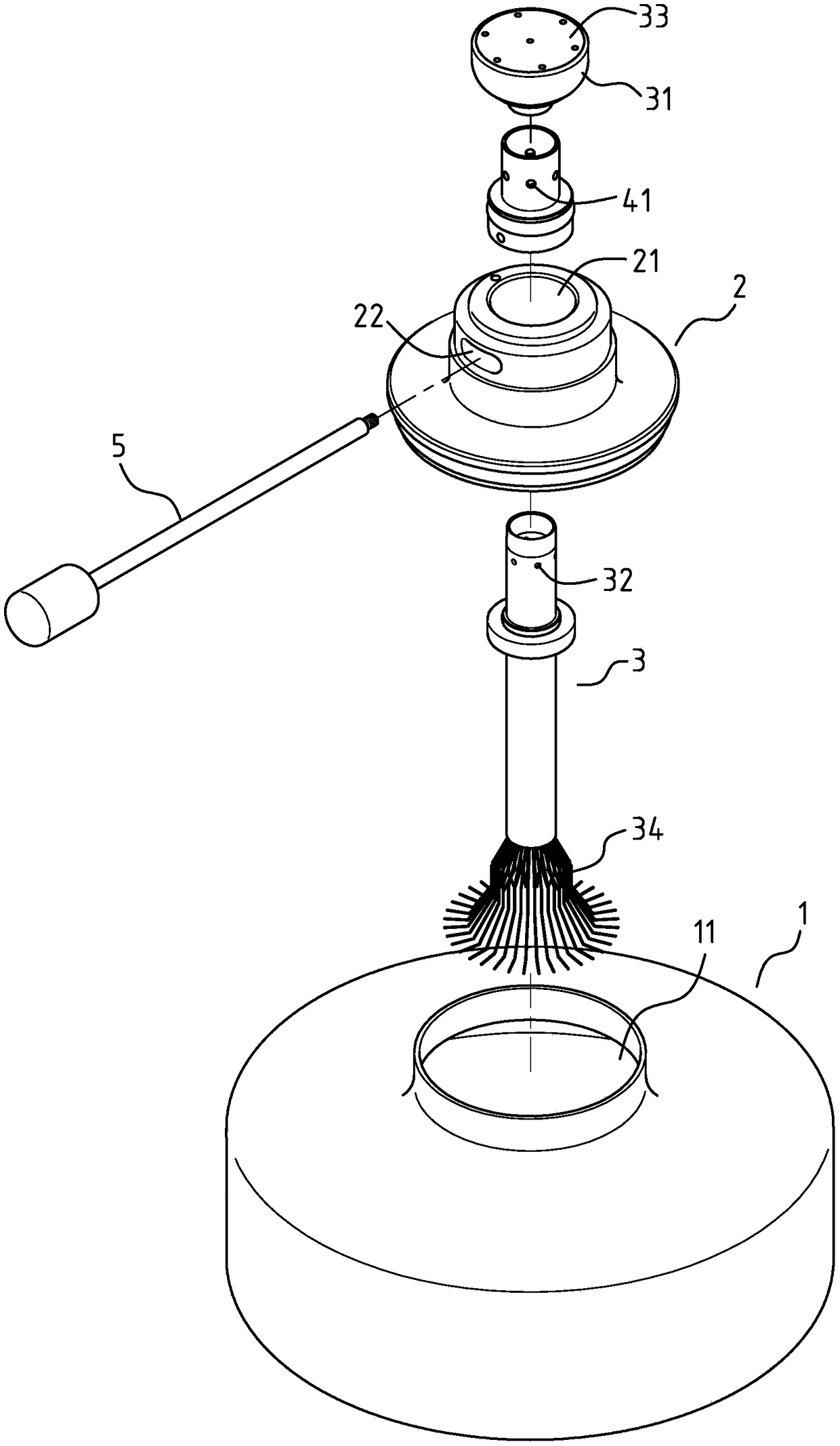

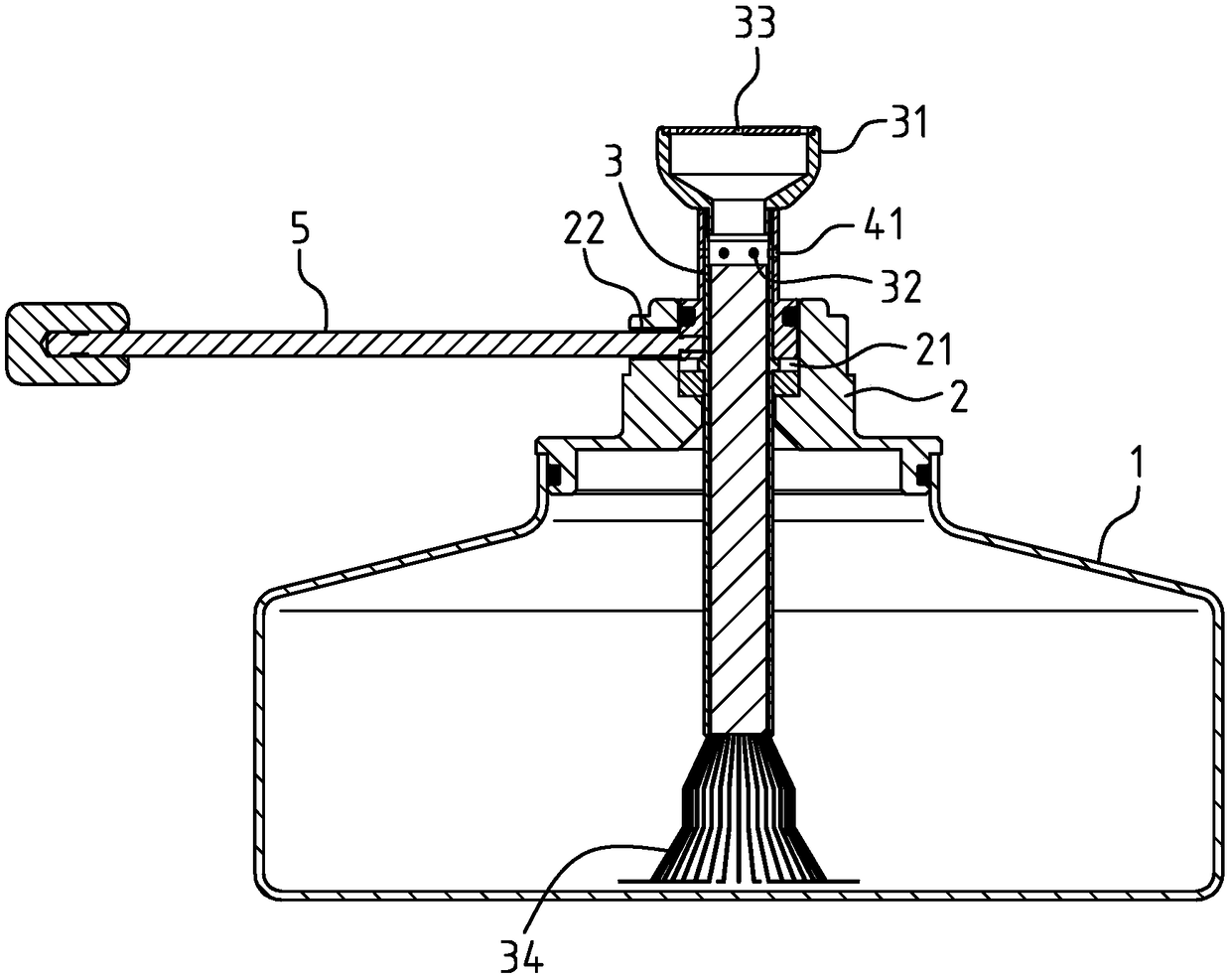

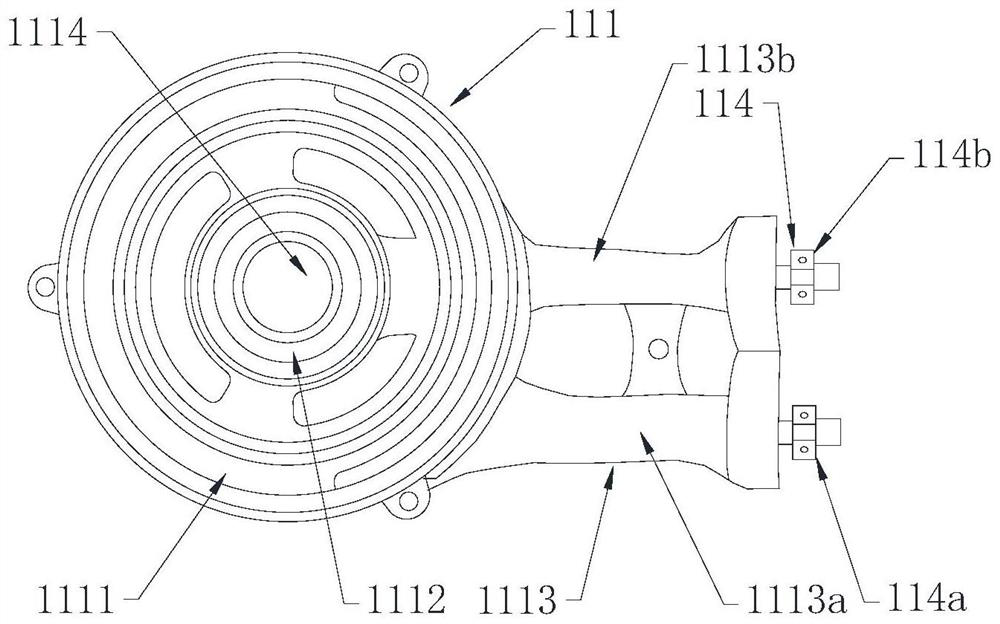

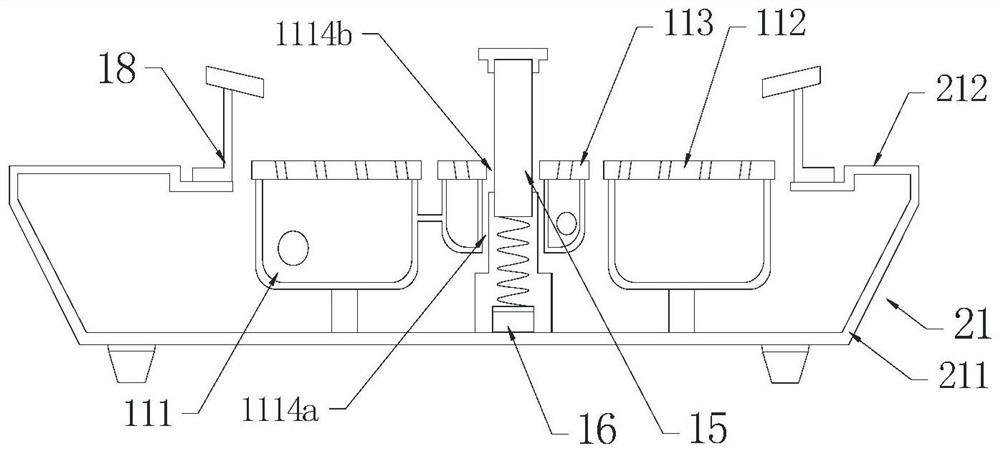

Off-pot detection device and detection method for stove

InactiveCN111829427AAdjust firepowerHigh sensitivityDomestic stoves or rangesLighting and heating apparatusControl theoryMechanical engineering

The invention discloses an off-pot detection device and method for a stove. The off-pot detection device comprises a controller, a telescopic assembly, a supporting assembly, a detection assembly anda stove body, wherein the telescopic assembly sleeves the supporting assembly and moves up and down along the supporting assembly, the detection assembly is connected with the controller and moves upand down along with the telescopic assembly, and the controller is connected with the stove body and used for controlling the firepower of the stove; and the detection assembly comprises a magnetic ruler and a linear magnetic encoder, wherein the magnetic ruler is connected with the telescopic assembly, the linear magnetic encoder is connected with the controller, and the linear magnetic encoder detects the displacement distance of the magnetic ruler through magnetism. The telescopic assembly moves downwards or upwards according to the state (pot seating or pot leaving) of a pot to drive the magnetic ruler to move up and down, the magnetic encoder can collect the displacement of the magnetic ruler moving up and down and transmit the displacement to the controller, and the controller judgesthe state of the pot according to the displacement so as to adjust the firepower. Compared with traditional cookware state detection based on temperature, the scheme has higher sensitivity.

Owner:VATTI CORP LTD

A gas valve for a cooker burner

ActiveCN104110504BAdjust firepowerPrecise adjustment of air intakeOperating means/releasing devices for valvesSlide valveCombustorHermetic seal

A gas valve of a stove burner comprises a valve body, a valve element, a vale rod, a pressure spring, a fine tuning pin and an electromagnetic valve. The valve body comprises a gas inlet cavity, a gas outlet and a gas guide cavity. The wall plate of the adjacent ends of the gas inlet cavity and the gas outlet is a valve element seat. The valve element seat is provided with a first gas guide passage communicated with the gas guide cavity. The gas guide cavity is communicated with the gas outlet through a second gas guide passage. The fine tuning pin is screwed to the gas guide cavity. The circular valve element is provided with a gas guide hole. The valve element and the valve element seat are fitted and in hermetic seal. The valve rod is fixedly connected with valve element. The end wall plate, opposite to the valve element seat, of the gas inlet cavity is provided with a valve rod passage. The valve rod and the valve rod passage are rotatably matched and in hermitic seal. One end of the pressure spring is matched with the valve element, and the other end thereof is matched with the end wall plate of the gas inlet cavity. An electromagnetic valve seat is communicated with the gas inlet cavity. By the structure, when the valve element rotates, the gas guide hole of the valve element coincides with the first gas guide passage to precisely adjust gas inlet amount so as to adjust the fire of the burner, and use convenience is achieved.

Owner:湖州市双林工业园区开发有限公司

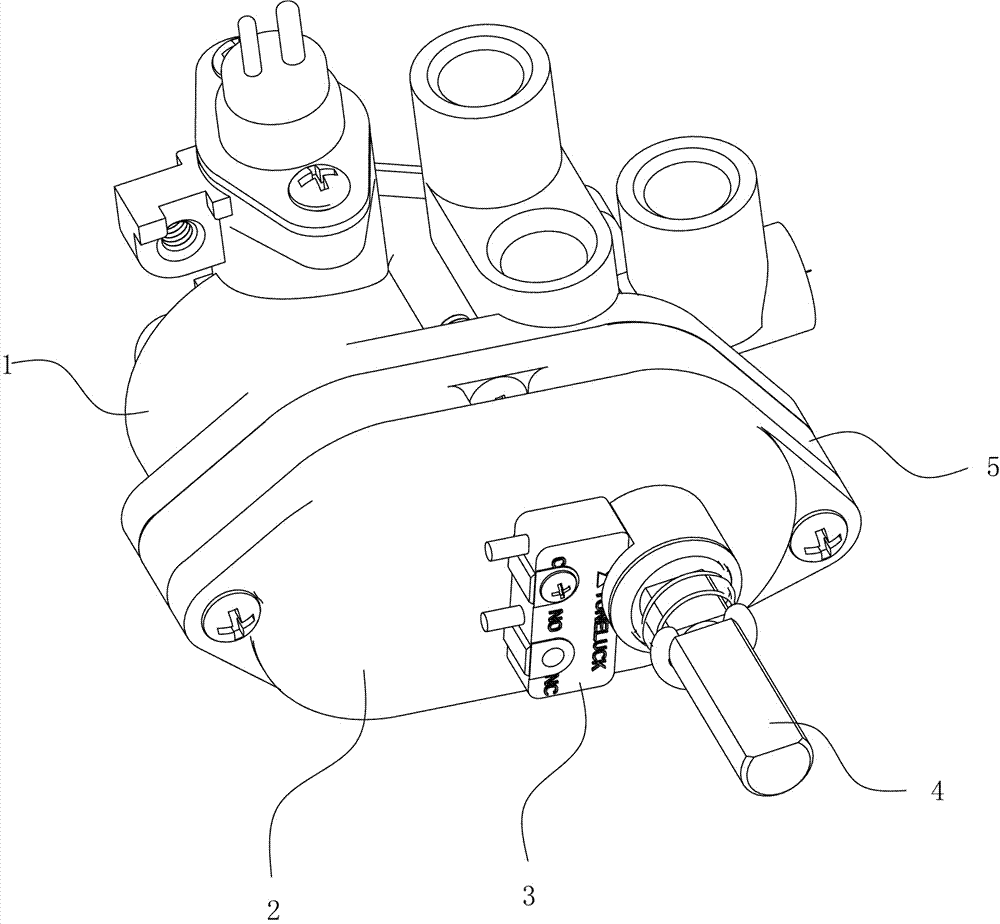

Fire-off device for gas cooker and gas cooker

ActiveCN108204607BTurn off the fire to achieveAdjust firepowerDomestic stoves or rangesLighting and heating apparatusRotary switchFire extinguisher

The invention discloses a fire switch for a gas stove and the gas stove and belongs to the field of household appliances. The fire switch for the gas stove comprises a clamping mechanism, a shell, anadjusting mechanism and a control device, wherein the shell, the adjusting mechanism and the control device are connected with the clamping mechanism; the adjusting mechanism comprises a drive part and an acting part which cooperate with each other; the acting part is configured to turn on the switch and driven by the drive part to rotate and adjust the switch; and the control device is configuredto control the drive part according to a preset pattern so as to control the acting part to turn on or rotate the switch selectively. The fire switch for the gas stove can control a fire of the gas stove more accurately, is novel in appearance, can be used without modification on an existing stove or natural gas conveying pipeline, and achieves the control effect.

Owner:湖南华军厨房设备有限公司

Liquid fuel furnace

The invention provides a liquid fuel furnace comprising a container, a base, a main pipe, an adjusting member and an adjusting rod, wherein the bottom end of the main pipe extends inside the container, the top end extends in the head space of the base, and the top end of the main pipe is provided with a heating cap, The adjusting member pivots the main pipe, the adjusting rod end is laterally connected to the adjusting member; the main pipe extends laterally through the plurality of first air outlet holes, and the heating device top end forms a second air outlet hole, and the second air outlethole communicates with the main pipe a plurality of inner cores are disposed in the main body, and the bottom ends of the inner cores extend inside the container, and the top ends of the inner coresare respectively adjacent to the bottom edges of the first air outlet holes; the adjusting member cooperates with the first air outlet side A plurality of third air outlet holes are penetrated, and each of the third air outlet holes is adjacent to each of the first air outlet holes. Operating the adjustment lever to rotate the adjustment member changes the amount of heat supplied to the heating cap, thereby changing the amount of heat that provides heat to the object to be heated.

Owner:吴建林

Method for controlling pot temperature and its use on pot

The present invention relates to a kind of pot temperature controlling method without power consumption, and the pot and heater therewith. Principally, the heat transferring liquid with heat expansion coefficient higher than that of pot material is utilized to generate one motion quantity for the heater to control temperature. The present invention is significant to control the heating temperature during cooking.

Owner:金向阳

a gas stove

ActiveCN106969387BAdjust firepowerEvenly heatedDomestic stoves or rangesLighting and heating apparatusThermodynamicsRice dishes

The invention belongs to the field of cookers, and specifically discloses a gas cooker, which includes a burner, an electrically controlled gas valve, a temperature sensor, a controller and a cooking program built in the controller. The air inlet of the electric control gas valve is communicated with the gas delivery pipe, and the air outlet is respectively communicated with the air inlet of the burner. The temperature sensor and the gas stove assembly are used to detect the temperature of the pot. Cooking programs are configured with time-related setpoints for pot temperature and time. The gas stove is suitable for automatically cooking soup, cooking rice, cooking porridge and pancakes. When cooking food, the controller obtains the cooking program corresponding to the food being cooked. During the cooking process, the controller controls the electric gas valve to adjust the firepower of the burner according to the set value and measured value of the pot temperature in the cooking program. , so that the measured value of the pot temperature reaches the set value until the cooking program is executed and the cooking is completed. During the entire cooking process, the gas stove automatically cooks the ingredients without the user's participation, and can also cook rice with crusts.

Owner:李明守

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com