Metal fuel gas singeing machine

A singeing machine, gas technology, applied in singeing, textile and papermaking, fabric surface trimming, etc., can solve problems such as large safety hazards, and achieve the effect of safe fabric, no damage to fabric, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

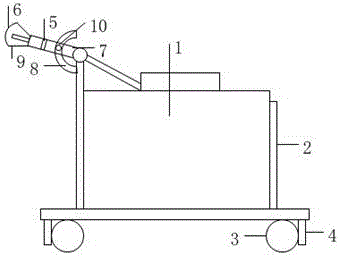

[0015] Such as figure 1 As shown, the structural diagram of the present invention, a metal gas singeing machine, is characterized in that it includes a gas tank 1, a metal sheet 6, a torch 7, and a base; the bottom of the base has a roller 3 and a brake pad 4 , The roller 3 is provided with a ring of rubber sleeve on one circumference; the rubber sleeve is provided with friction lines; the brake pad 4 is a rubber brake pad, and the thickness of the brake pad 4 is 3mm; the machine There is a holder 2 above the seat, the gas tank 1 is arranged in the holder 2, and one end of the torch 7 is movably fixed above the holder 2; the body of the torch 7 has a protruding screw 10 , The screw 10 is clamped into the arc-shaped groove 8 above the clamping frame 2, and can be fixed by a nut at any point therein; the metal sheet 6 is fixed to the socket by two or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com