Heating cooking equipment and oil temperature control method thereof

A technology for cooking equipment and oil temperature, which is used in utensils, household appliances, and applications for frying things in oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

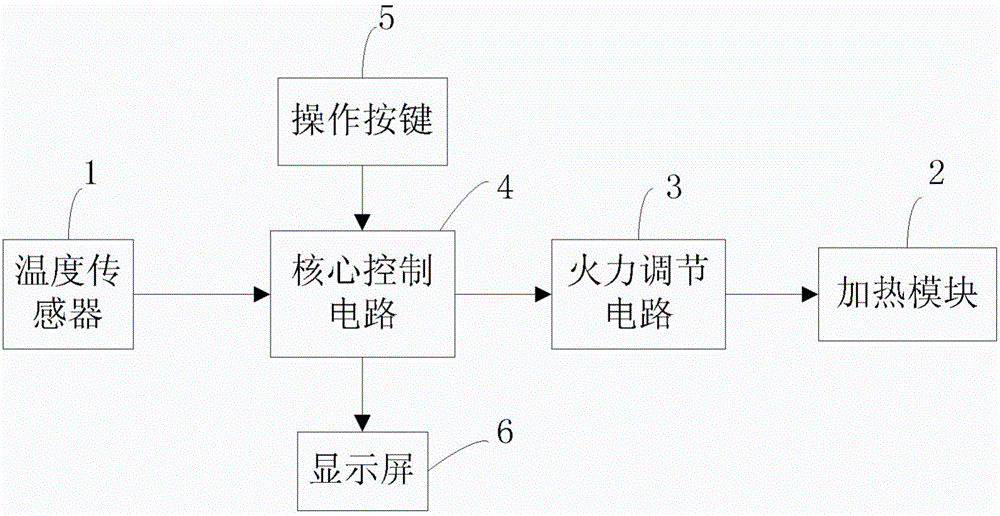

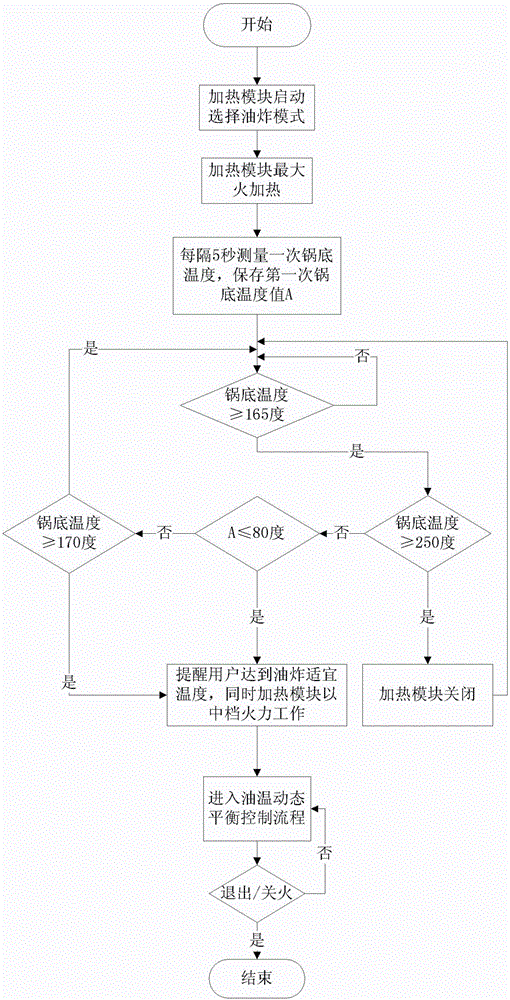

[0033] Such as figure 1 The heating and cooking equipment shown includes a temperature sensor 1 for detecting the temperature of the bottom of the pot in real time, a heating module 2, a firepower adjustment circuit 3 for adjusting the firepower of the heating module, and a core control circuit connected to the firepower adjustment circuit to control the firepower adjustment circuit 4. The temperature sensor 1 is also connected with the core control circuit 4, and the core control circuit is also connected with an operation button 5 for selecting the operating mode of the core control circuit and a display screen 6 for displaying the current state and cooking mode; Set with "Frying" working mode.

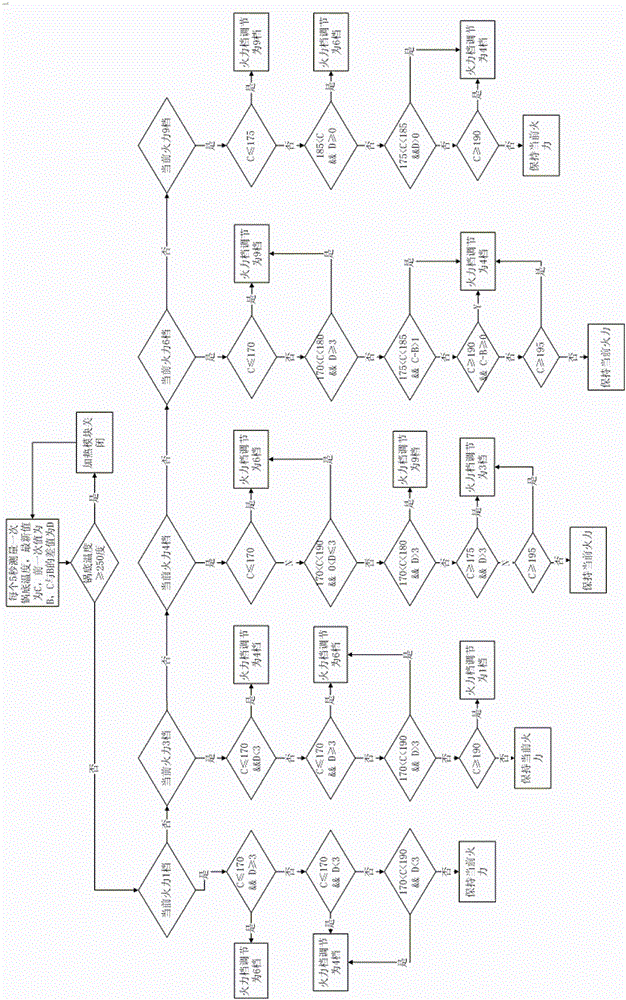

[0034] The core control circuit can accept the duration of warming the fire and cooking soup input by the user. The specific execution steps of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com