Plug valve

A plug valve and valve core technology, applied in the field of plug valves, can solve problems such as inconvenient use and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

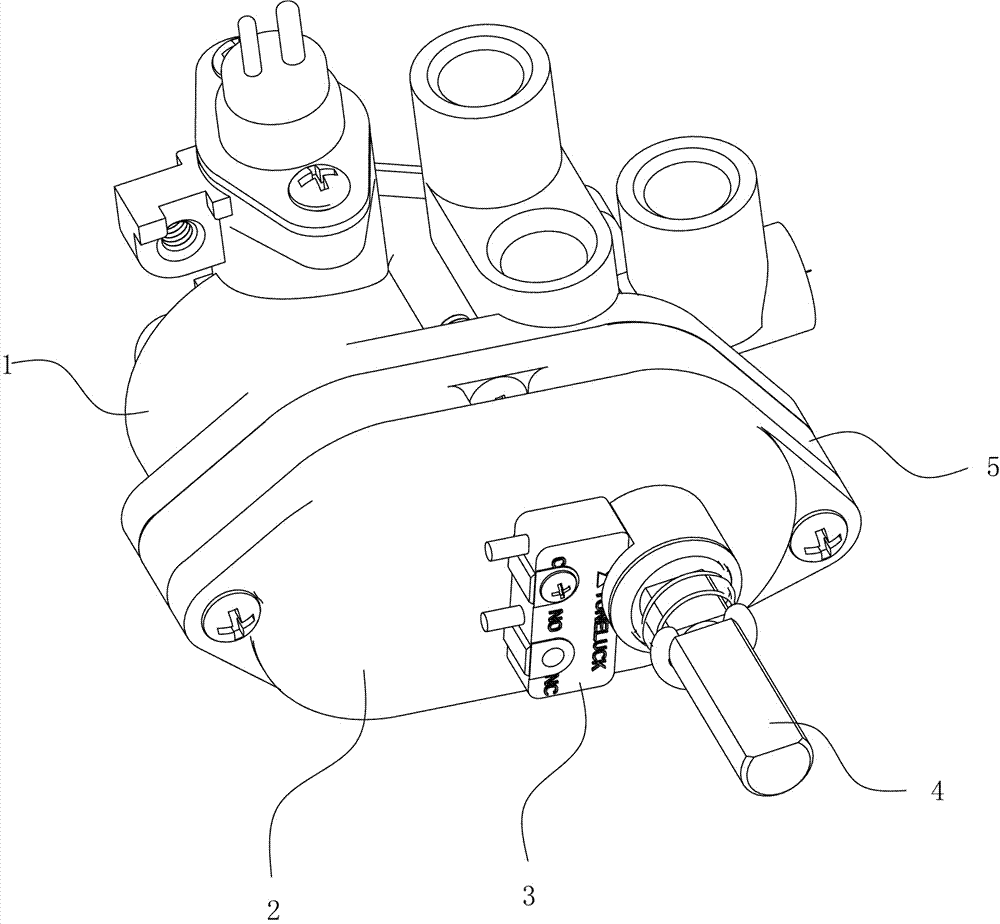

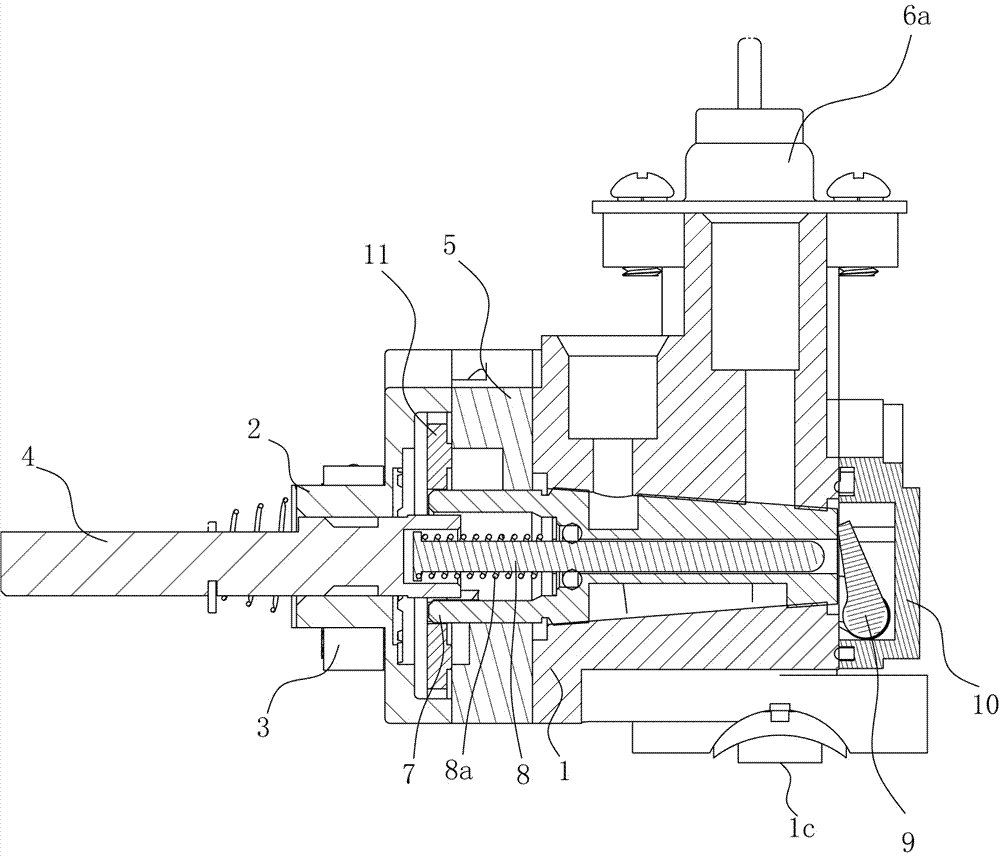

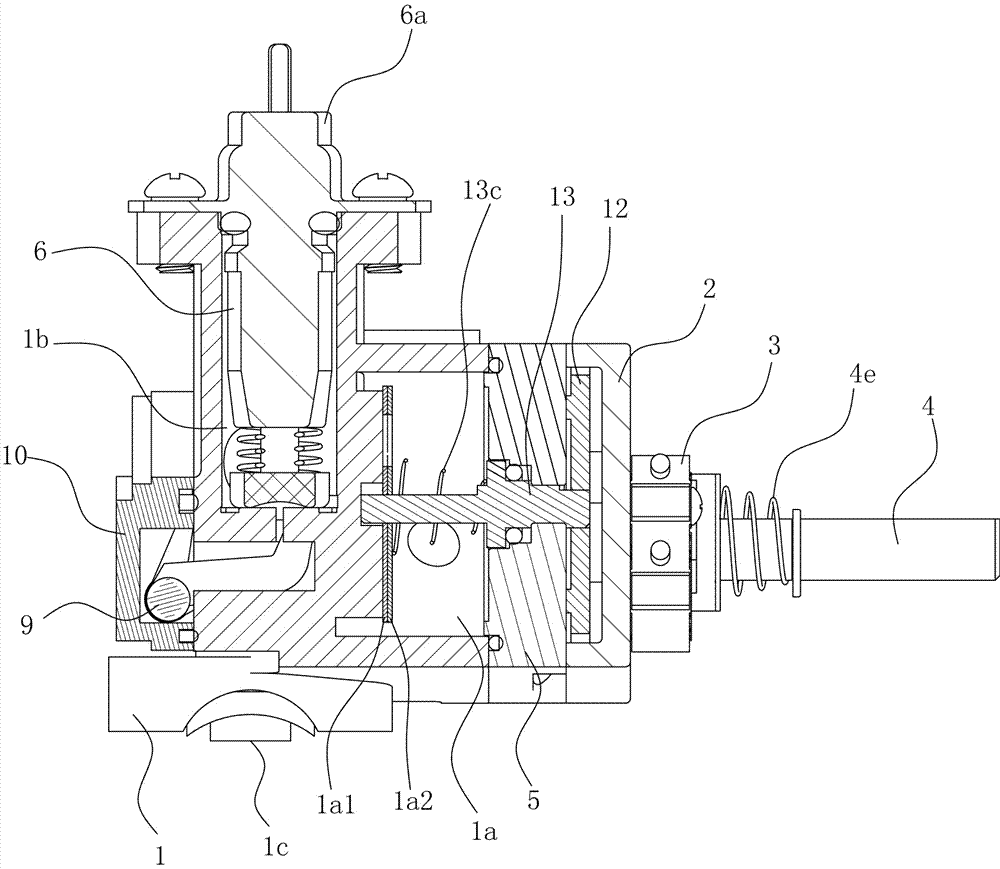

[0028] Figure 1 to Figure 9A plug valve is shown, which includes a valve body 1, on which a spool accommodating cavity is arranged, and a spool 7 is arranged in the spool accommodating cavity, and the two are connected in a rotating and sealed manner. The body 1 is also provided with three gas outlets respectively connected to the outer ring, the middle ring and the inner ring on the burner head of the gas stove. A ventilation groove, rotates with the valve core 7, the size of the ventilation groove communicated with the air outlet is different and can completely close the air outlet, the center of the valve core 7 is provided with a thimble 8, and the thimble 8 and the The spool 7 is connected in a sliding and sealed manner, a spring B8a is provided between the thimble 8 and the spool 7, a rear cover 10 is provided at the rear of the valve body 1, and the sealing between the rear cover 10 and the valve body 1 connected, and a rotatable push rod 9 is arranged between the two...

Embodiment 2

[0031] Figure 10 to Figure 13 It is the second embodiment of the present invention. The difference between embodiment 2 and embodiment 1 is that the valve body 1 of embodiment 2 is provided with two air outlets, and the valve core 7 is provided with two interconnected ventilation grooves. The air sheet 1a1 is provided with a through hole I, the through hole I is composed of a ventilation part and a gas distribution part, the ventilation part is a fan-shaped through hole 1a1a', and the gas distribution part includes a left gas distribution part and a right gas distribution part The left air distribution part is composed of interconnected fan-shaped through-holes A'B' and fan-shaped through-holes B'A', and the right air distribution part is composed of interconnected fan-shaped through-holes C'C' and Composed of fan-shaped through holes D'D', the width of each fan-shaped through hole in the gas distribution part along its radial direction is fan-shaped through-hole A'B'>fan-sha...

Embodiment 3

[0033] Embodiment 3 is basically the same as Embodiment 2, except that the width of the left air distribution part on the first air distribution plate 1a1 in embodiment 3 gradually increases along the direction of rotation of the air distribution plate, and the width of the right air distribution part along the direction of the air distribution plate The direction of rotation gradually narrows.

[0034] Compared with the prior art, the present invention has the following beneficial effects: the present invention adds an air distribution chamber to the valve body of the plunger valve; At least one side along the rotation direction of the gas distribution plate is provided with an air distribution groove connected with the air hole. The air distribution groove extends along the rotation direction of the gas distribution plate. The air distribution groove and the air hole can be partially or completely covered when the gas distribution plate rotates. In the air inlet in the air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com