Automatic control alcohol-based fuel gasification burner and preparation method thereof

A technology of alcohol-based fuel and gasifier, which is applied in the direction of combustion method, combustion equipment, burner control device, etc. It can solve the problems of high combustion energy consumption, insufficient combustion, and low firepower, so as to protect the atmospheric environment and facilitate firepower The size, the effect of increasing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

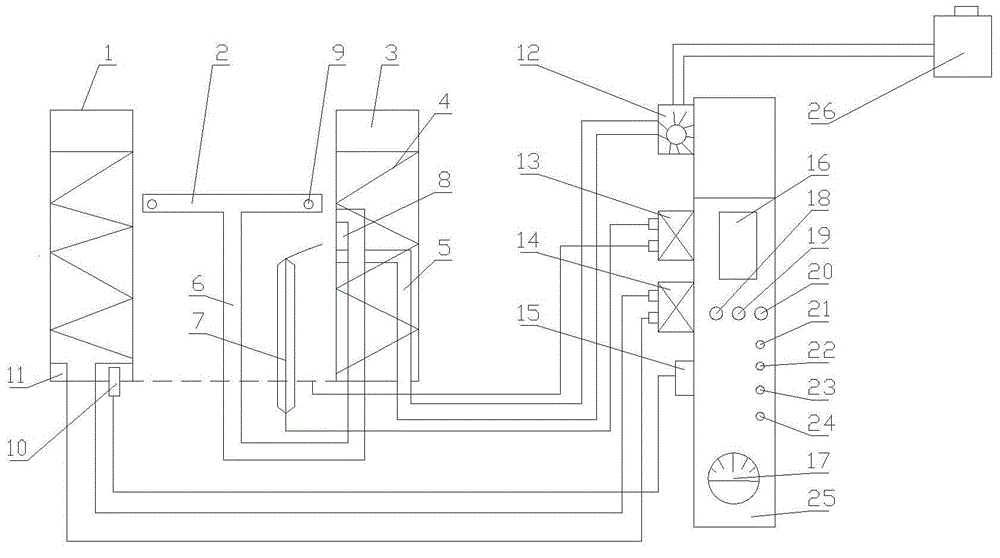

[0028] In order to further disclose the content of the invention, features and effects of the present invention, the following examples are given as a special example and described in detail as follows:

[0029] An automatic control alcohol-based fuel gasification burner includes a burner tube and a gas nozzle with exhaust holes in the burner tube.

[0030] The innovative points of the present invention include:

[0031] The furnace barrel is made of two coaxial hollow cylinders and is made into a cylinder with a sealed cavity. The inside of the sealed cavity is a heating chamber, and a cracking cavity and an electric heating corner are arranged in the heating chamber. There is a gasification pipe connected with the lower end of the gas nozzle and an oil inlet pipe connected with an oil pump, the oil pump is connected with the oil storage tank; an electronic ignition needle connected in the microcomputer controller is also arranged in the furnace barrel.

[0032] The innovati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com