Energy-saving and environment-friendly industrial waste gas combustion treatment device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

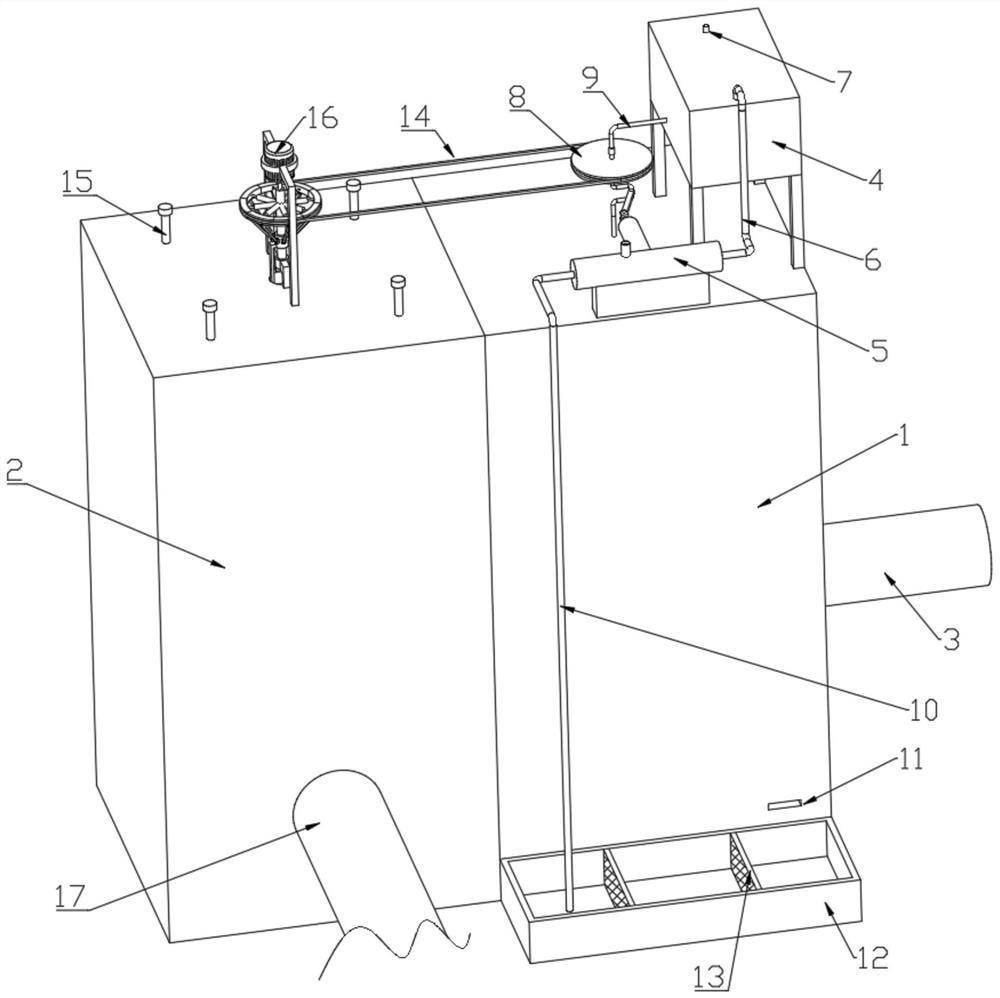

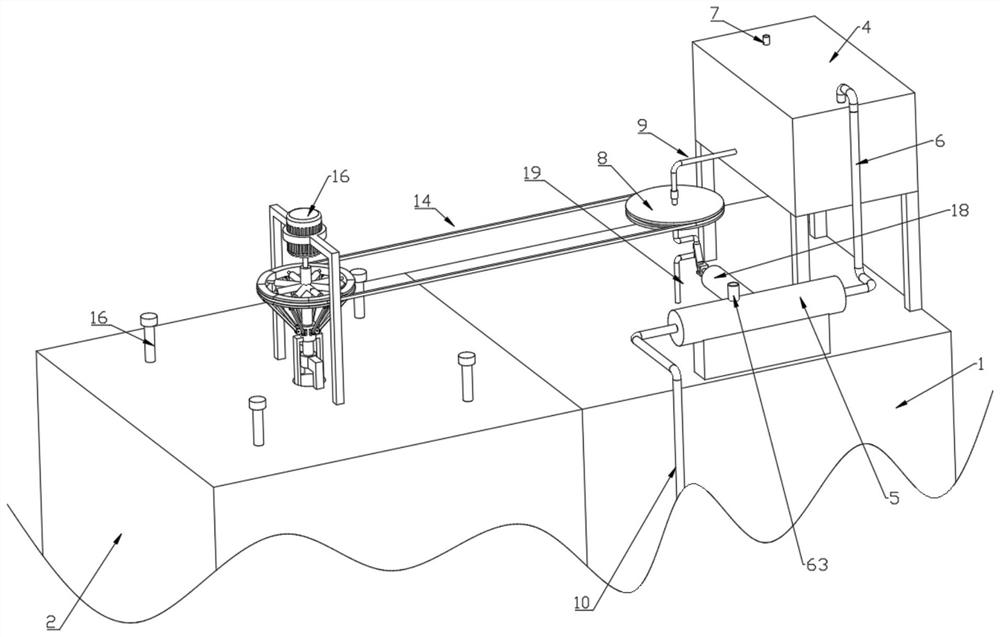

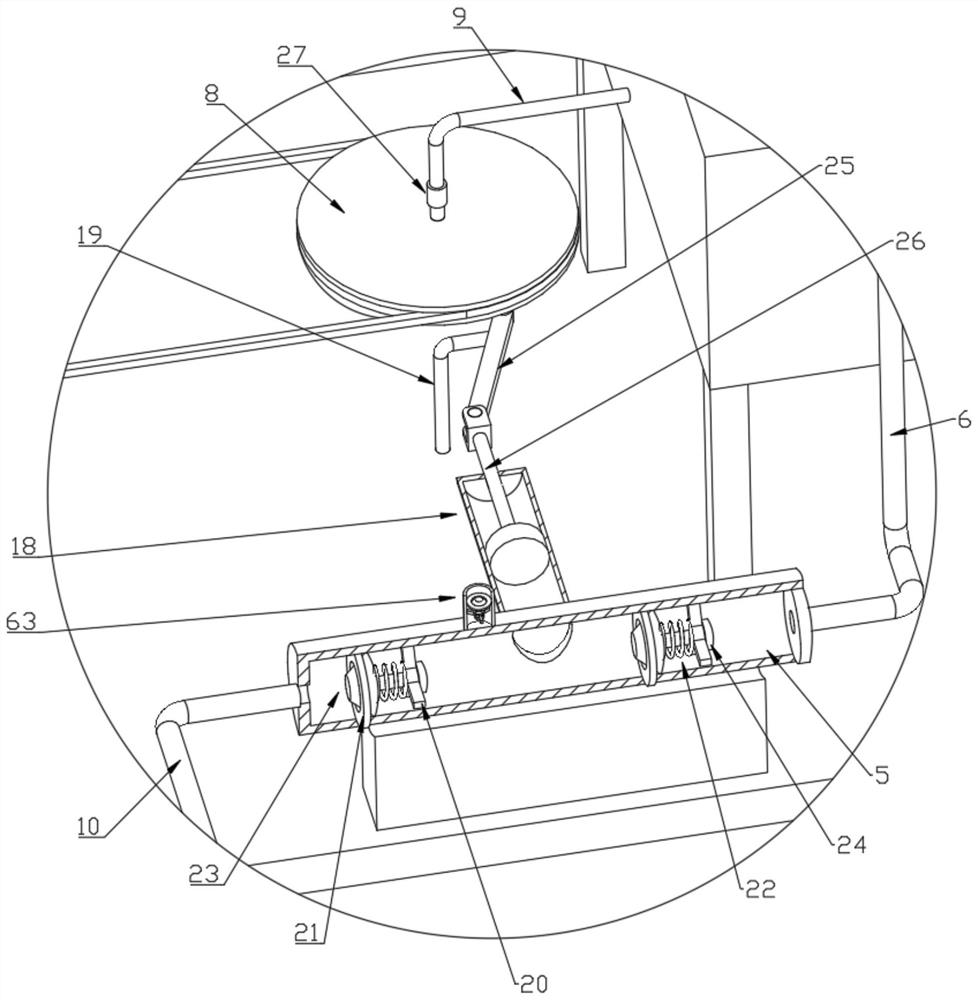

[0031] see figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , an energy-saving and environment-friendly industrial waste gas combustion treatment device, comprising a spray tower 1 and an incinerator 2, the incinerator 2 is provided with a spray drive module, the spray drive module includes a combustion chamber 40, and the combustion chamber 40 is arranged on the incinerator 2 Inside, the inwall of combustion chamber 40 is provided with flame vent 39, and combustion chamber 40 is positioned at the position below flame vent 39 to be provided with air vent 62, and the upper end of combustion chamber 40 is provided with steam box 41, and steam box 41 is provided with water, steam box The upper end of 41 is provided with slide plate 42, and the upper end of slide plate 42 is fixedly connected with slide bar 15, and the upper end of slide bar 15 runs through the upper end of incinerator 2, and slide bar 15 is positioned at the end outer wall cover in inciner...

Embodiment 2

[0044] see Figure 12 , in this embodiment, other structures remain unchanged, and the present invention also provides another structural form of the nozzle 48. Preferably, the nozzle 48 is a tubular nozzle, and the nozzle 48 is bent and arranged obliquely on the third rocker. 61 lower end. The reaction force produced when the water flow is ejected from the shower nozzle 48 can push the rocker 3 61, so that the nozzle 48 rotates and sprays when the water guide pipe 19 is assisted.

[0045] The working principle of Embodiment 1 of this application: please refer to figure 1 , Figure 6 , Figure 7 , the exhaust gas passes into the spray tower 1 through the intake pipe 3, the water tank 4 passes water through the connecting pipe 9 into the water pipe 19, passes into the cross 55 through the water pipe 19, and passes through the water inlet pipe 260 on the cross 55. Rod 3 61 is finally sprayed out from the nozzle 48 to realize the function of settling the particles in the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com