A gas valve for a cooker burner

A burner, gas valve technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problem of inability to achieve precise control, and achieve the effect of achieving firepower and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

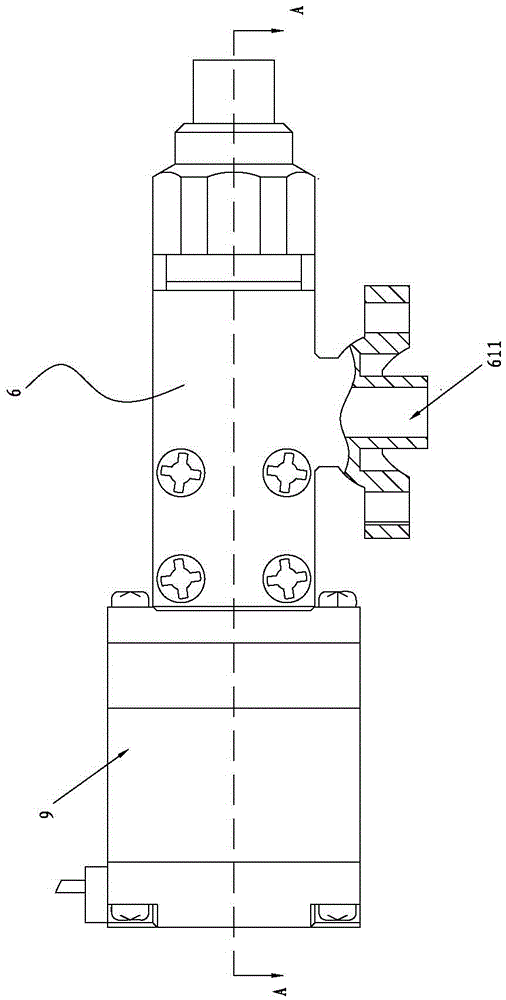

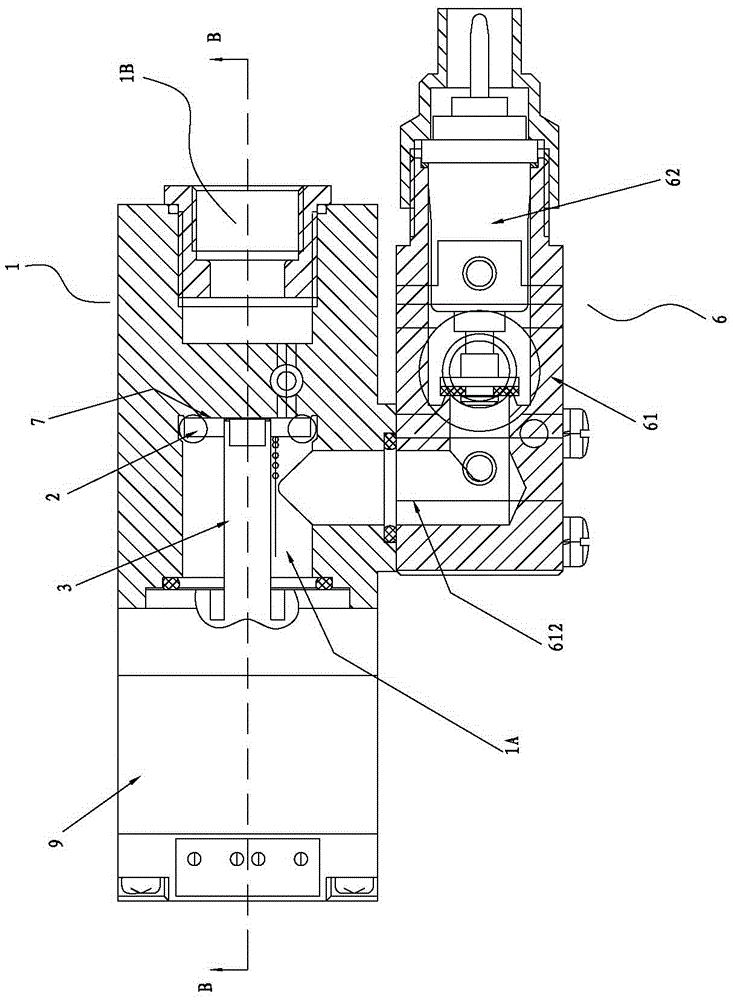

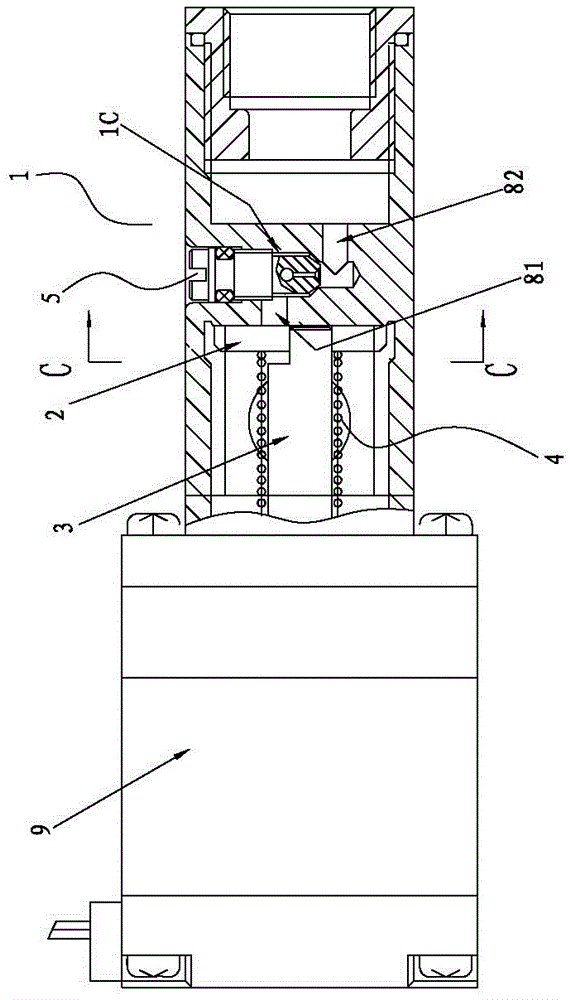

[0024] Such as figure 1 , figure 2 , image 3 As shown, a gas valve for a stove burner includes a valve body 1, a valve core 2, a valve stem 3, a pressure spring 4, a fine-tuning nail 5 and a solenoid valve 6, and the solenoid valve 6 includes a solenoid valve seat 61 and a solenoid valve The core body 62 and the solenoid valve seat 61 have an air inlet port 611 and an air outlet port 612 .

[0025] The valve body 1 includes an air inlet chamber 1A, an air outlet 1B and an air guide chamber 1C, the wall plate at the adjacent end of the inlet chamber 1A and the air outlet 1B is a valve core seat 7, and the valve core seat 7 has a first air guide channel 81 It communicates with the air guide chamber 1C, the air guide chamber 1C communicates with the air outlet 1B through the second air guide channel 82, and the fine-tuning nail 5 is screwed into the air guide chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com