Downhole completion device with liquid

A liquid and shell technology, applied in wellbore/well components, measurement, earthwork drilling and production, etc., can solve problems such as endangering sensor functions and pressure rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

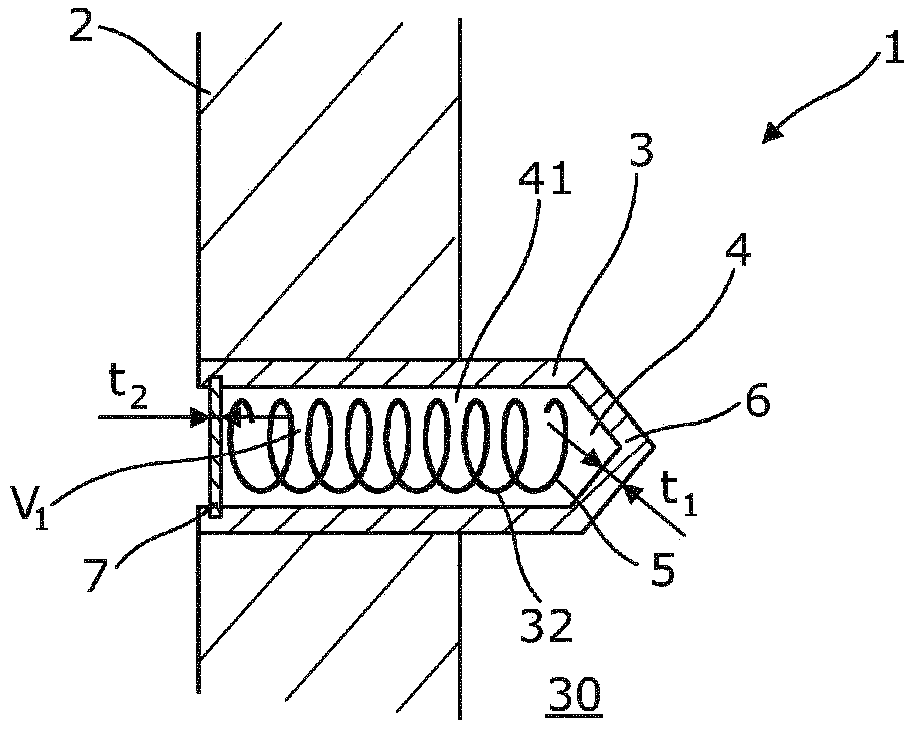

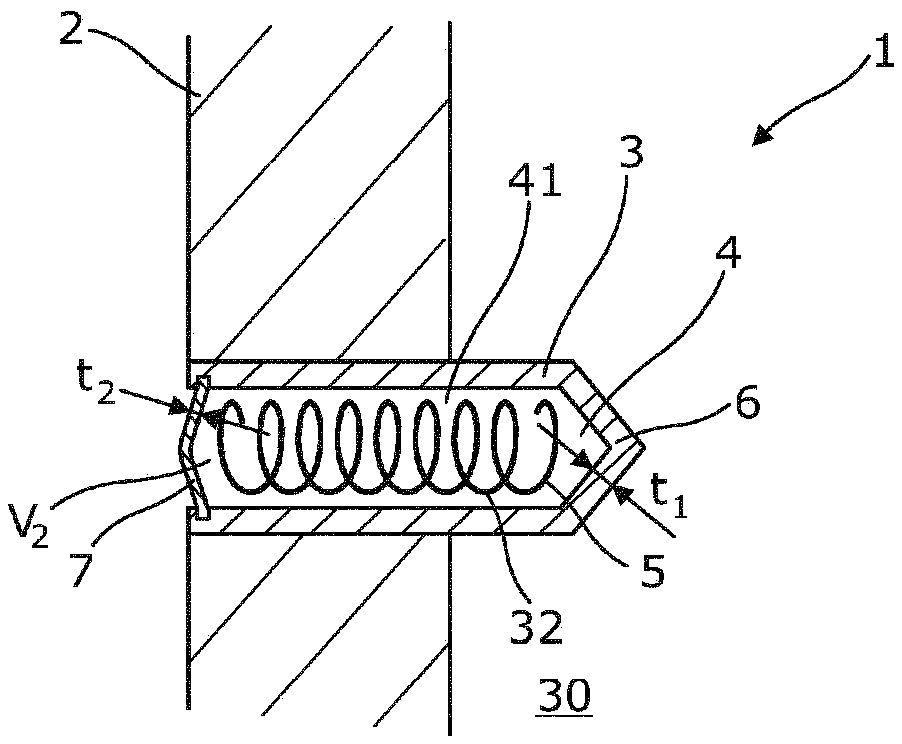

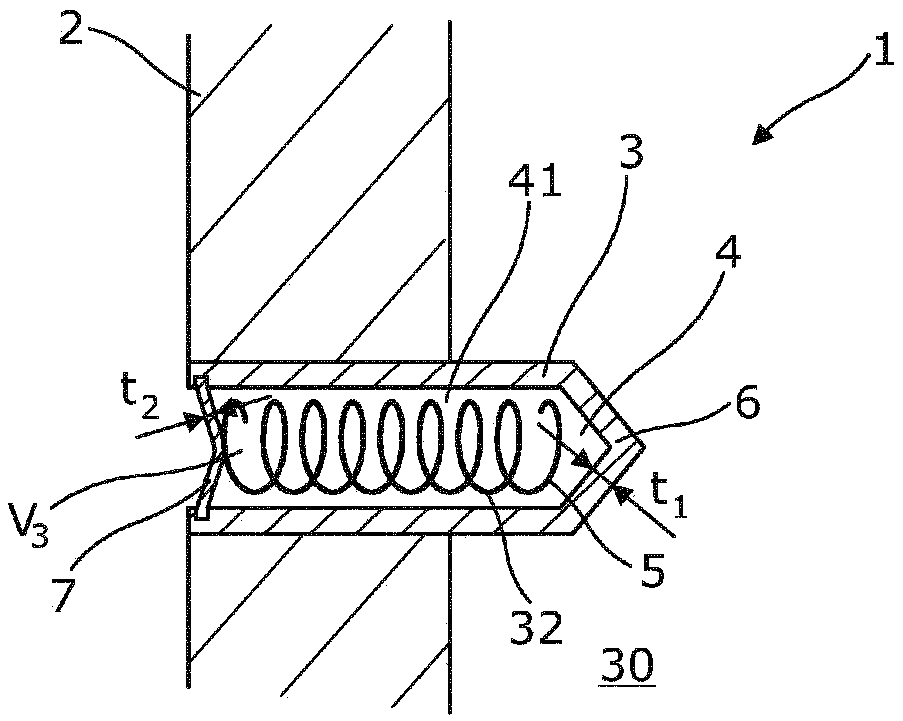

[0058] figure 1 Shown is a downhole completion 1 configured to be installed in a wellbore 30 as part of a metallic well tubular structure 2 . The downhole completion device 1 comprises a housing 3 enclosing a closed space 4 and electrical components 5 , such as coils 32 , arranged in the space inside the housing. The housing 3 is filled with a liquid 41 having a first volume V of 1 bar at 20°C 1 . The housing 3 has a first housing section 6 and a second housing section 7 . The first housing section 6 has a first thickness t 1 , the second housing section 7 has a second thickness t 2 , the second thickness is less than the first thickness such that the second shell section is more flexible than the first shell section. When the temperature in the well increases, the pressure in the enclosed space 4 increases correspondingly. This makes the second housing section 7 as figure 2 Protruding radially outwards towards the inside of the metal well tubular structure 2 to the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com