Water pipe for sewage filtration

A technology for water pipes and sewage, applied in the direction of filtration and separation, filtration circuits, separation methods, etc., can solve the problems of sewage not being able to circulate normally, residues that are not easy to clean, and water pipes bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

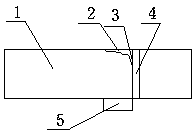

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, the water pipe for sewage filtration includes a pipe body 1, a connecting plate 2, a scraper 3, a filter screen 4 and a sedimentation area 5, the pipe body 1 has a built-in filter screen 4, and the sedimentation area 5 is placed in the pipe body 1 , and located on one side of the filter screen 4, one end of the connecting plate 2 is connected to the inner wall of the pipe body 1, and the other end is connected to the scraper 3, and the side wall of the scraper 3 is attached to the filter screen 4.

[0012] The inner wall of the pipe body 1 is provided with a slideway, and one end of the connecting plate 2 is placed in the slideway.

[0013] The connecting plate 2 is an arc plate.

[0014] During use, when the water flow passes, the impact connecting arm 2 lifts the scraper 3, the water flows through the filter screen 4, and the sedim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com