Printer

A printer and printing technology, applied in the direction of typewriter, printing, winding strip, etc., can solve the problems of affecting the printing quality and unable to remove the meandering of the ribbon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, the printer according to this embodiment will be described in detail with reference to the drawings. In addition, this invention is not limited by the Example demonstrated below.

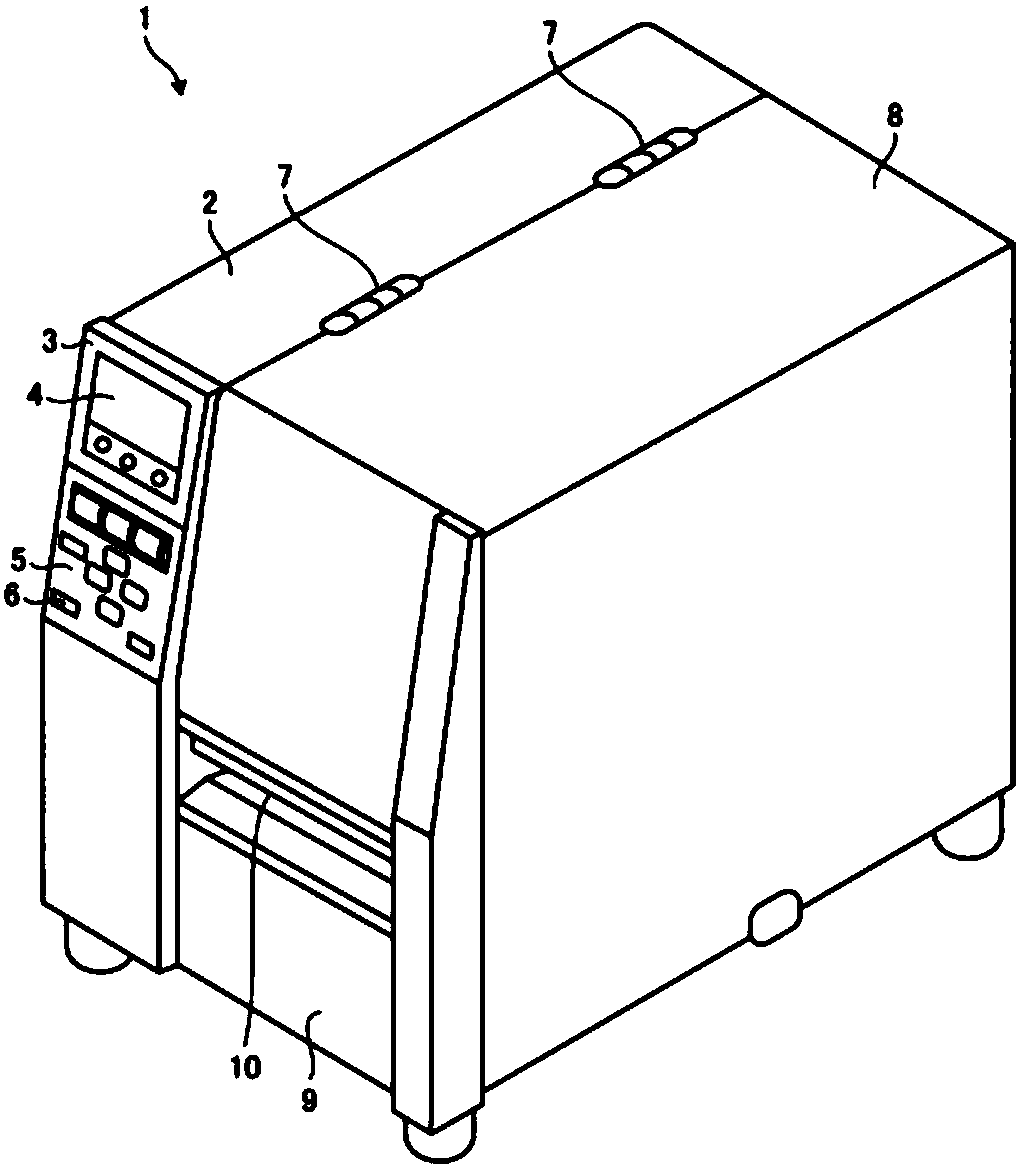

[0042] figure 1 It is an external perspective view of the printer 1 of this embodiment. Such as figure 1 As shown, the printer 1 has a casing 2 on the left side, and a casing 8 connected to the right side of the casing 2 by a hinge 7 . The front panel 3 of the housing 2 has a display unit 4 and an operation unit 5 . The display unit 4 is composed of a liquid crystal display with a backlight, but other types of display devices may also be used. The operation unit 5 has a plurality of operation buttons 6 .

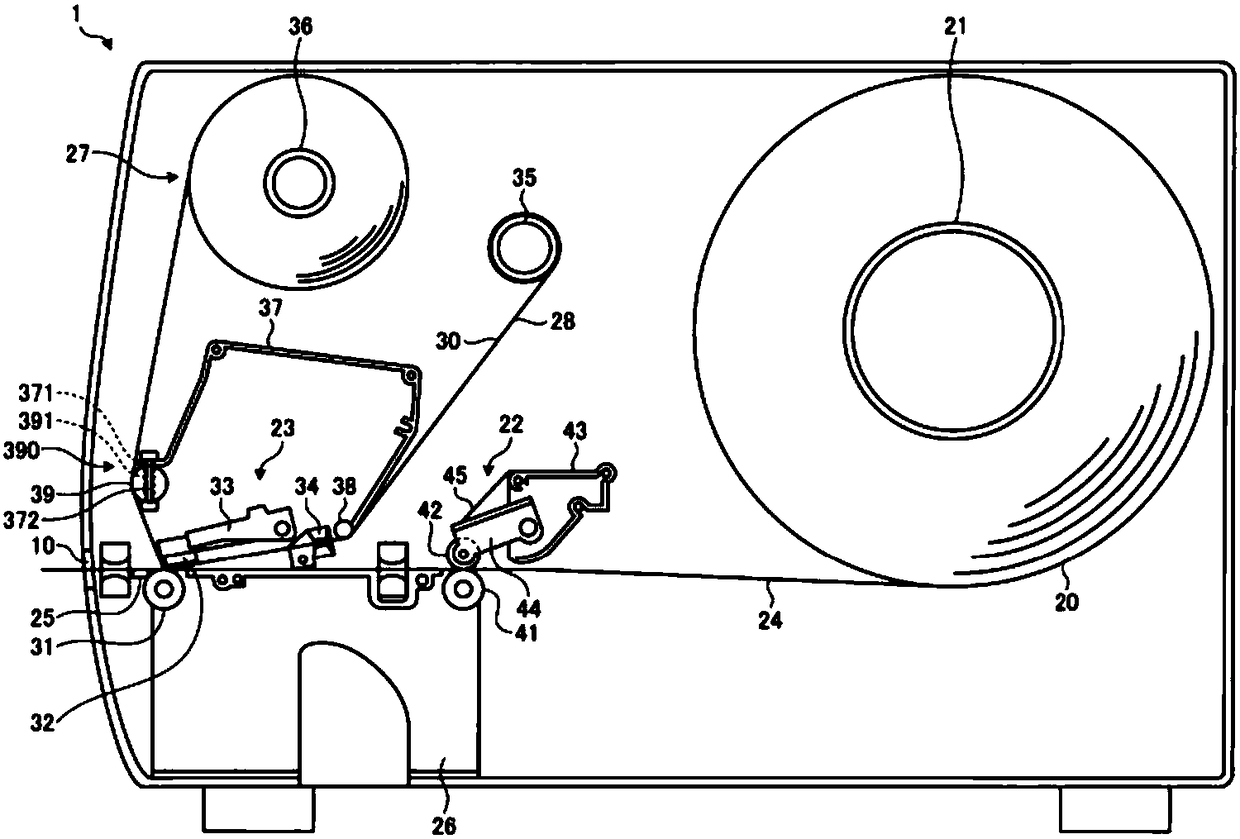

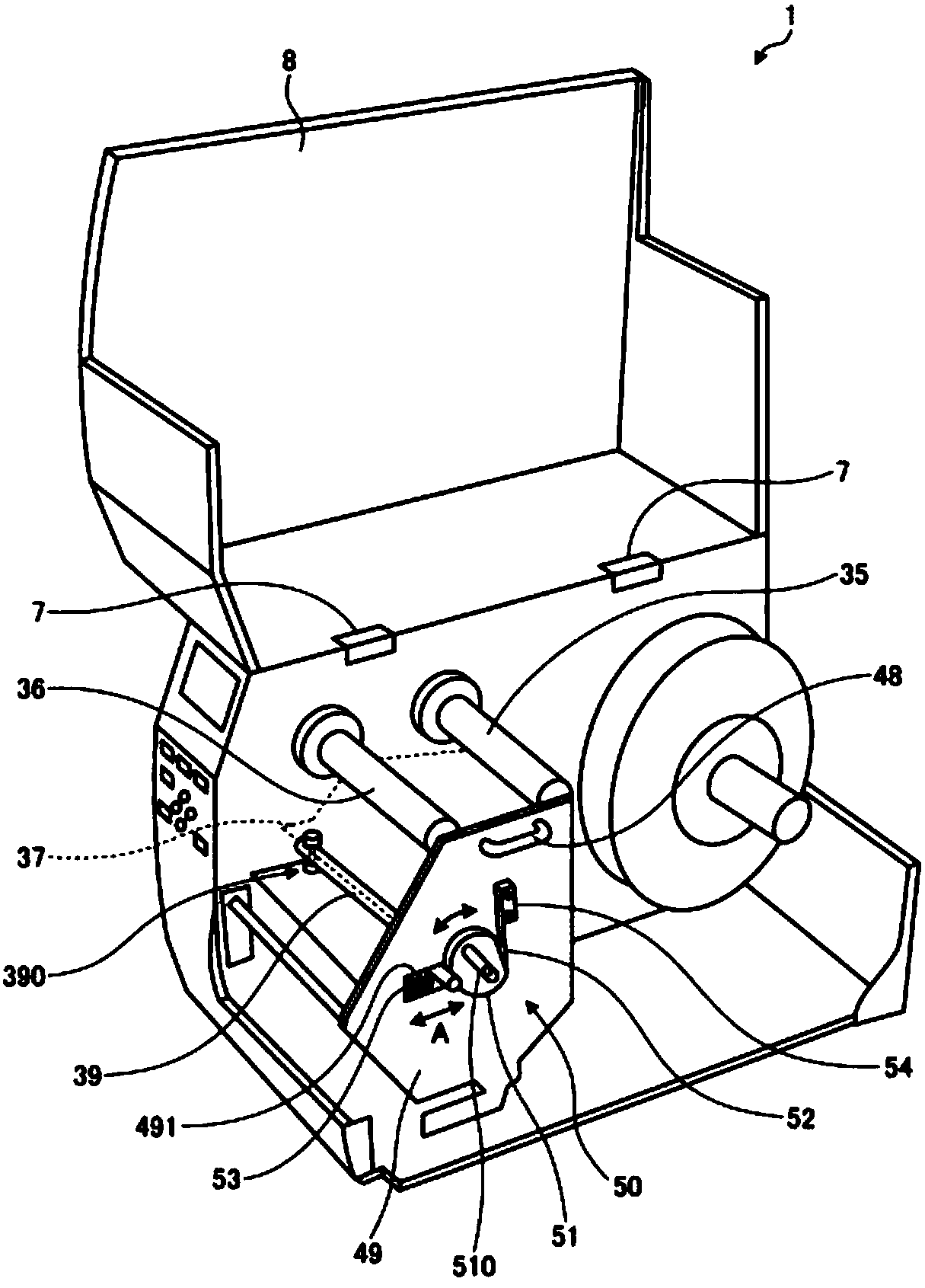

[0043] The housing 8 on the right has a structure in which the inside of the housing (that is, the housings 2 and 8 ) can be largely opened by rotating the hinge 7 . Although with figure 2 While it will be described later, the printer 1 has a label paper 20 wound into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com