Stone-plastic wooden-core flat internal corner line

A technology of inner corner line and stone plastic, applied in the direction of construction and building structure, can solve the problems of affecting the overall effect and aesthetics of decoration, affecting aesthetics, poor firmness, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

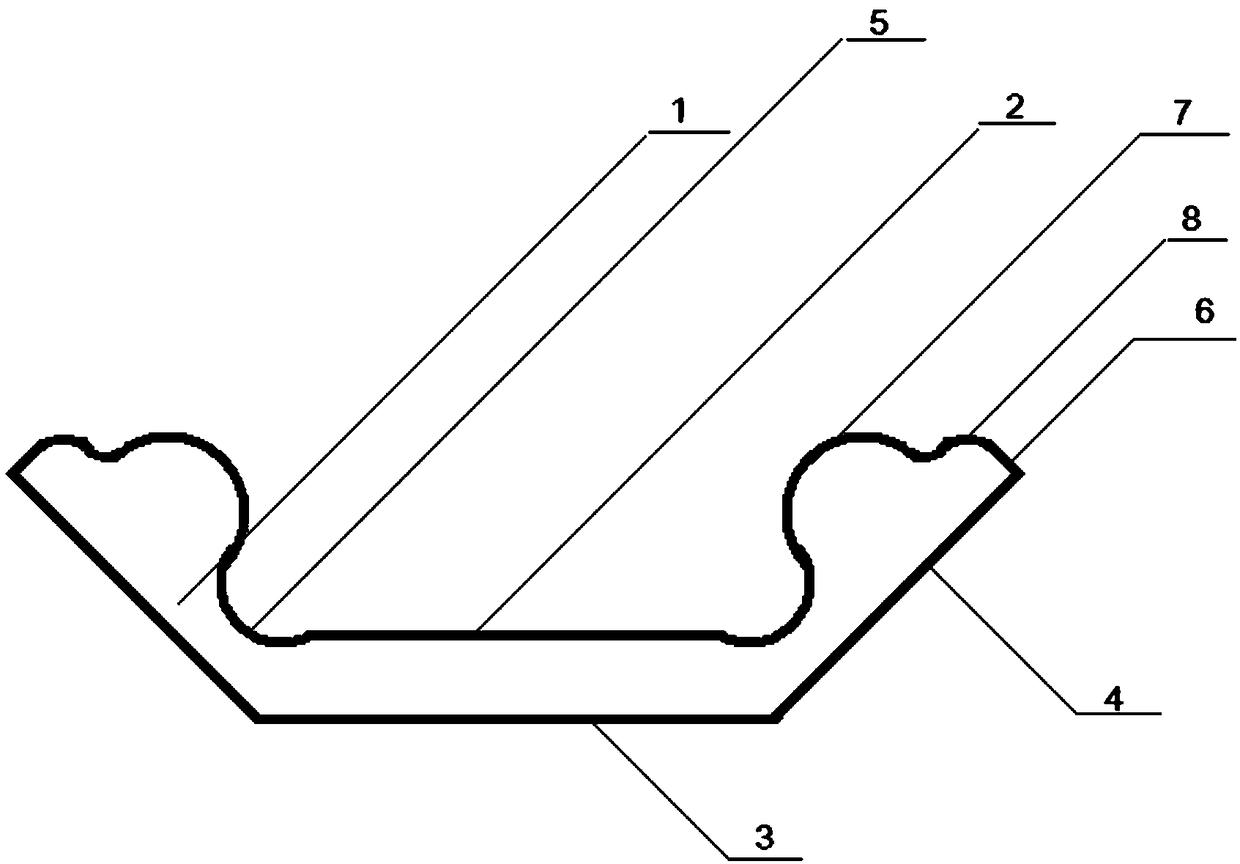

[0015] Embodiment 1: A stone-plastic wood core flat corner line, the line body 1 is a slender strip shape pressed by stone powder, the line body 1 is a wooden inner core wrapped with stone plastic, and the cross-sectional shape of the line body 1 is In the middle is a planar middle plane 2, on both sides of the middle plane 2 are semicircular concave arc-shaped concave arcs 5, the outer side of the concave arc 5 is connected with a semicircular protrusion 7, and the outer side of the semicircular protrusion 7 is connected with a small arc 8, and a small arc 8 The outer side is connected with mutually perpendicular trimming surfaces 6; the bottom surface of the line body 1 is provided with a planar bottom surface 3, and both sides of the bottom surface 3 are sticking surfaces 4 that are perpendicular to each other and glued to the wall.

Embodiment 2

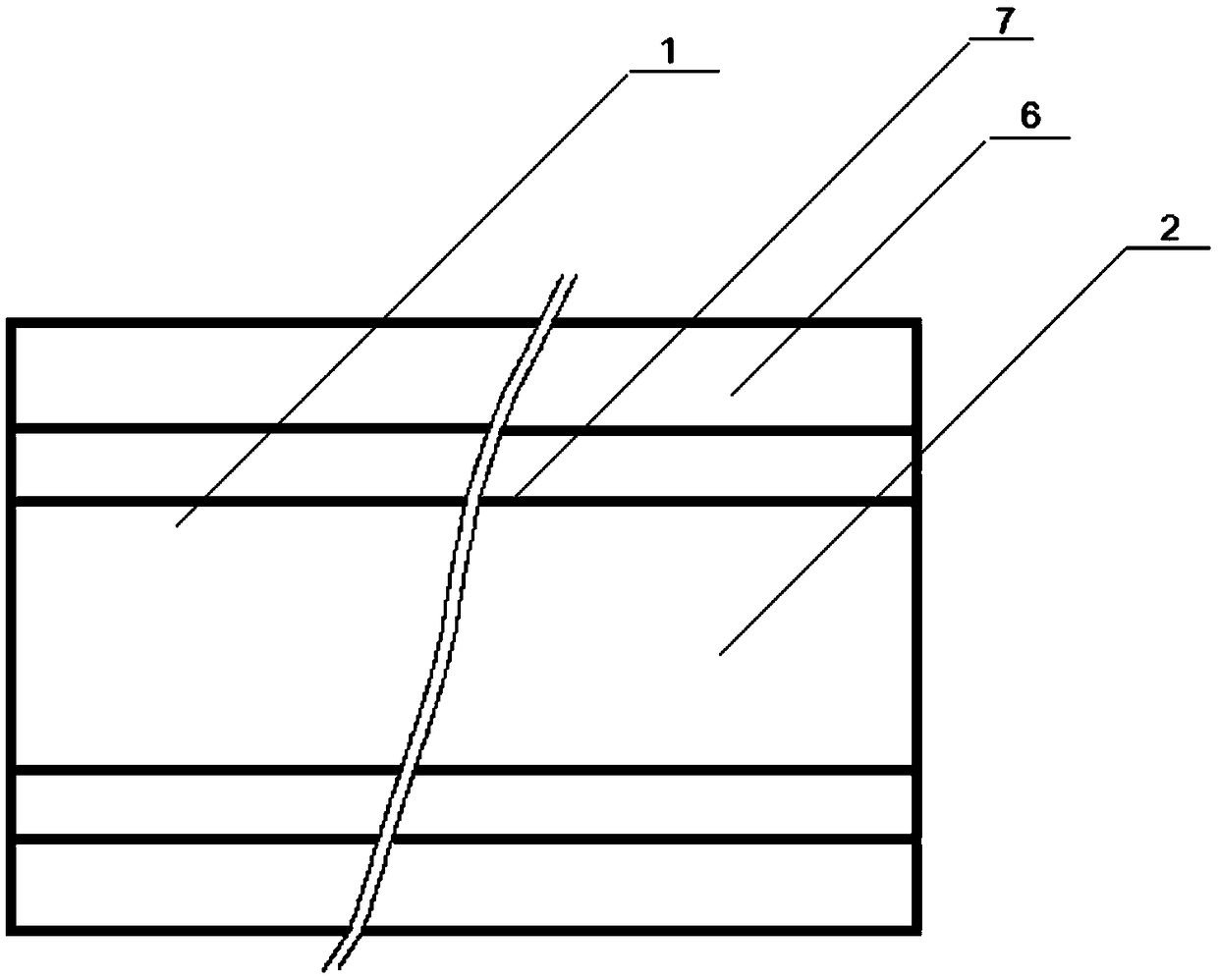

[0016] Embodiment 2: A stone-plastic wood core flat corner line, the line body 1 is a long and thin shape pressed by stone powder, the line body 1 is a wooden inner core wrapped with stone plastic, and the cross-sectional shape of the line body 1 is In the middle is a planar middle plane 2, on both sides of the middle plane 2 are semicircular concave arc-shaped concave arcs 5, the outer side of the concave arc 5 is connected with a semicircular protrusion 7, and the outer side of the semicircular protrusion 7 is connected with a small arc 8, and a small arc 8 The outer side is connected with mutually perpendicular trimming surfaces 6; the bottom surface of the line body 1 is provided with a planar bottom surface 3, and both sides of the bottom surface 3 are sticking surfaces 4 that are perpendicular to each other and glued to the wall. The surface of the strip body 1 is sequentially provided with a pattern layer, a primer protection layer and a wear-resistant layer.

Embodiment 3

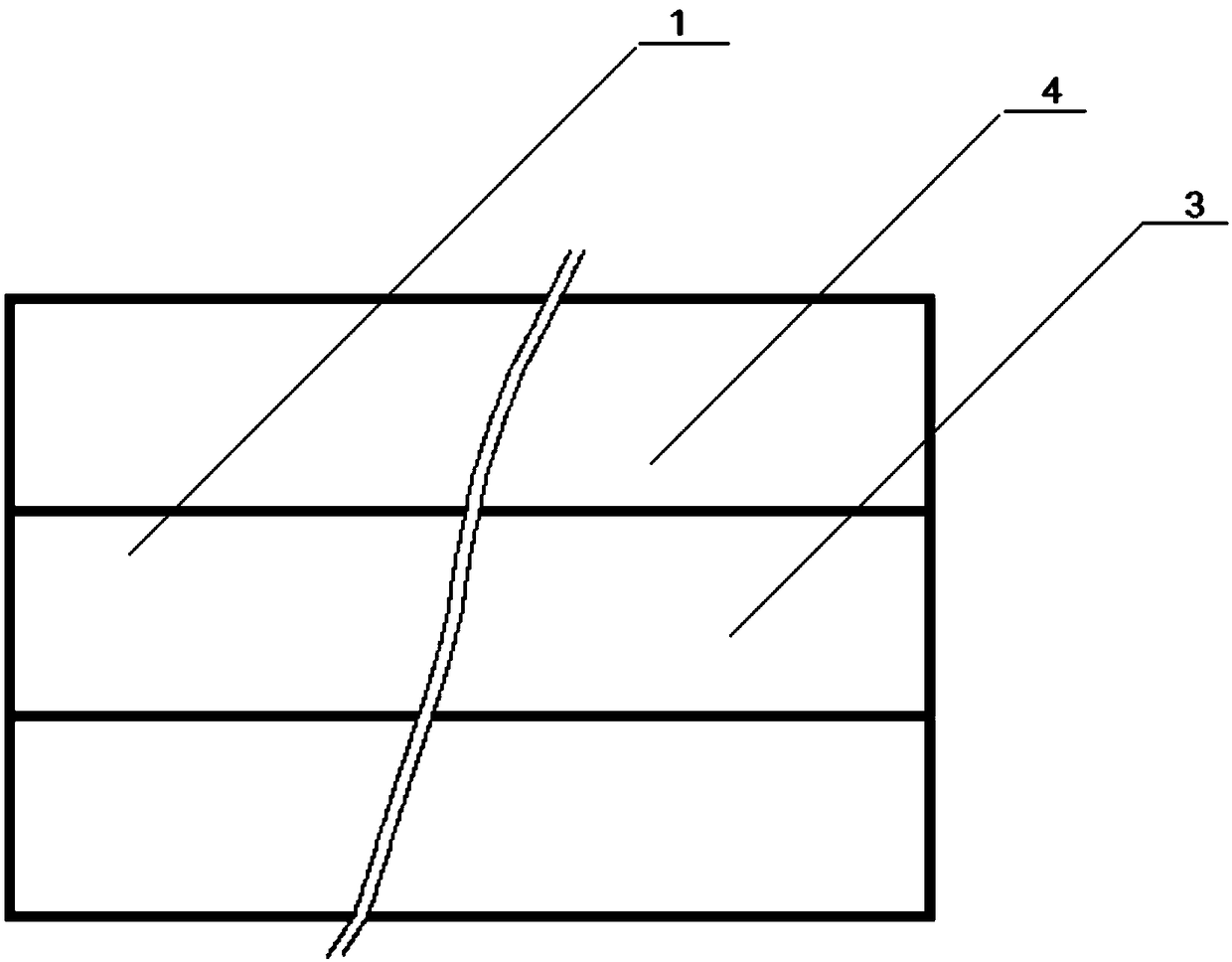

[0017] Embodiment 3: A stone-plastic wood-core flat corner line, the line body 1 is a slender strip shaped by pressing stone powder, the line body 1 is a wooden inner core wrapped with stone plastic, and the cross-sectional shape of the line body 1 is In the middle is a planar middle plane 2, on both sides of the middle plane 2 are semicircular concave arc-shaped concave arcs 5, the outer side of the concave arc 5 is connected with a semicircular protrusion 7, and the outer side of the semicircular protrusion 7 is connected with a small arc 8, and a small arc 8 The outer side is connected with mutually perpendicular trimming surfaces 6; the bottom surface of the line body 1 is provided with a planar bottom surface 3, and both sides of the bottom surface 3 are sticking surfaces 4 that are perpendicular to each other and glued to the wall. The surface of the strip body 1 is sequentially provided with a pattern layer, a primer protection layer and a wear-resistant layer. The stic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com