Device and method for testing permeability of hydrate coal containing gas

A testing device, hydrate technology, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve changing temperature conditions, uncontrollable hydrate coal body, permeability testing device cannot provide, etc. problems, to achieve the effect of ensuring safe production and reducing the accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

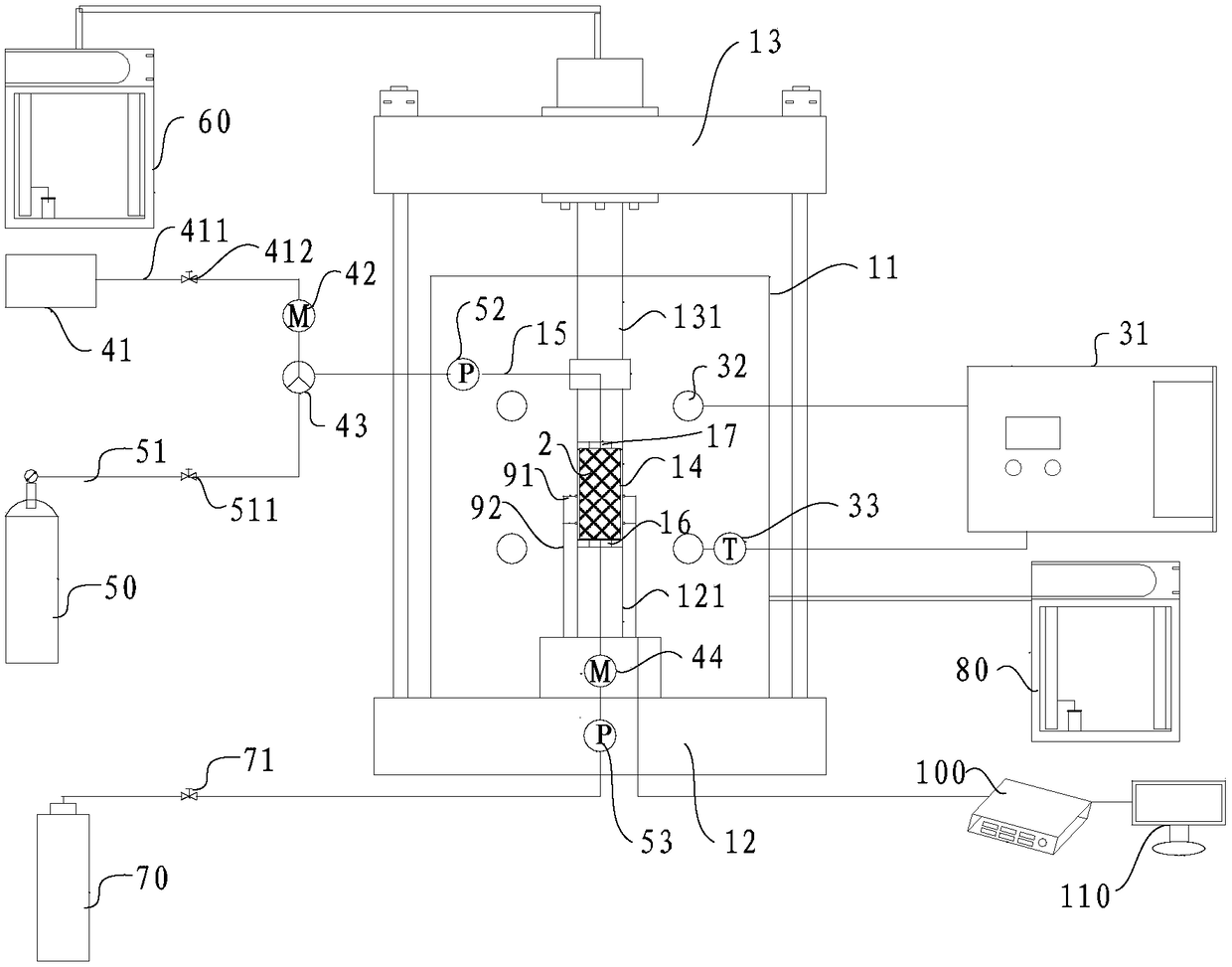

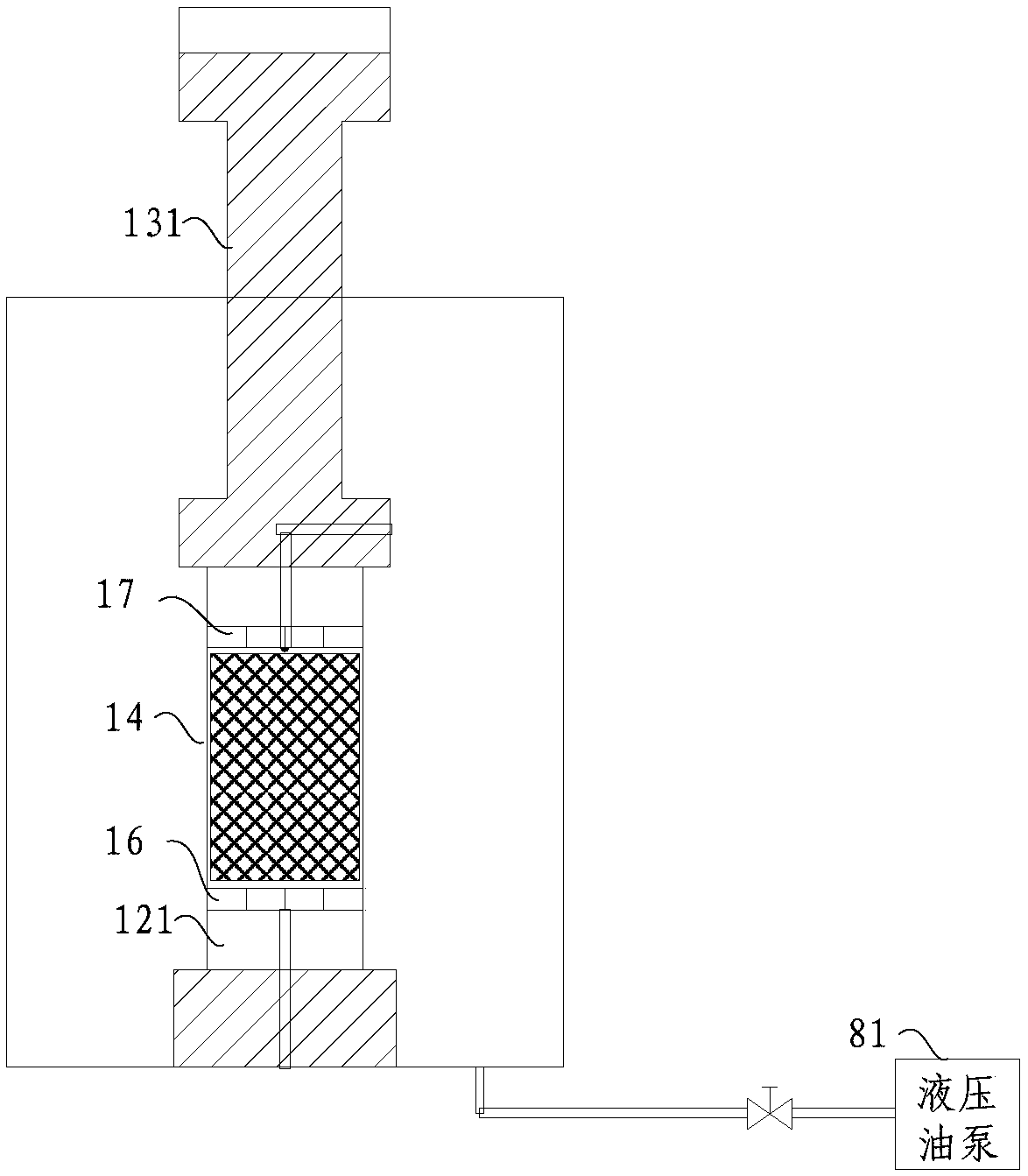

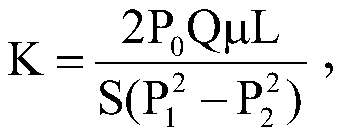

[0034] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS 1. The first aspect of the present invention provides a gas hydrate-containing coal permeability testing device, which combines figure 1 As shown, it includes a hydrate generation unit, a temperature control unit, a water injection unit and a gas cylinder 50. The hydrate generation unit includes a reaction kettle 11, a lower pressure head 12, an upper pressure head 13, a sample tube 14 and an injection pipeline 15. The sample The tube 14 is used to place the coal sample 2, the lower port of the reaction kettle 11 is sealed by the lower pressure head 12, and the upper port is sealed by the upper pressure head 13; the lower center pressure rod 121 of the lower pressure head 12 is inserted into the lower port of the sample tube 14, and the upper pressure The upper center pressure rod 131 of the head 13 is inserted into the upper port of the sample tube 14; the injection pipeline 15 is connected to the sample tube 14 through ...

specific Embodiment approach 2

[0073] Specific embodiment 2. Another aspect of the present invention also provides a method for testing the permeability of gas hydrate-containing coal, which is realized based on the gas hydrate-containing coal permeability testing device. The test method includes:

[0074] Control the axial pressurization pump 60 so that the upper central pressure rod 131 contacts the upper air-permeable steel plate 17, the coal sample 2, and the lower air-permeable steel plate 16 in sequence;

[0075] Pass silicone oil into the reaction kettle 11 through the hydraulic oil pump 81, and make the inner confining pressure of the reaction kettle 11 reach the confining pressure target value through the confining pressure booster pump 80;

[0076] Use the water injection unit to inject a set amount of water into the coal sample 2;

[0077] The gas cylinder 50 is used to continuously inject the gas gas of the target pressure into the coal sample 2, so that the coal sample 2 reaches an adsorption e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com