Method and system for calculating power-off time of new energy automobile

A new energy vehicle and accumulated time technology, applied in the field of new energy vehicles, can solve problems such as inaccurate acquisition of TBOX power-off time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

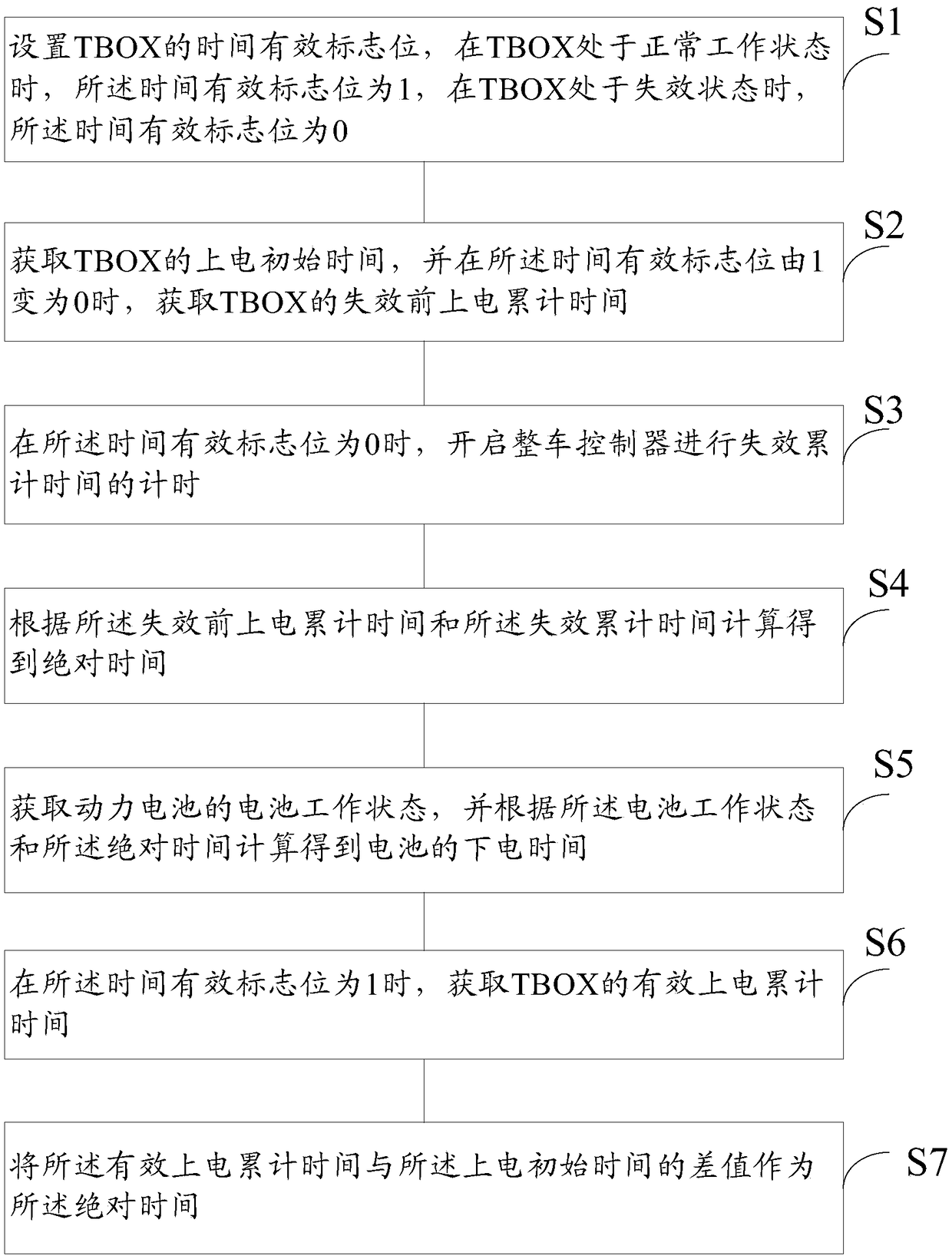

[0034] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

[0035] For the current new energy vehicles, only TBOX is used to monitor the power-off time, which may lead to inaccurate power-off time acquisition when TBOX fails or malfunctions. The present invention provides a method and system for calculating the power-off time of a new energy vehicle. By setting the TBOX time effective flag bit, the accumulated power-on time of the TBOX is obtained when the time effective flag bit is 1, and the entire time is obtained when the time effective flag bit is 0. The cumulative failure time obtained by the vehicle controller is counted, and then the power-off time of the whole vehicle is calculated. Solve the problem that the power-off time of new energy vehicles is mainly monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com