Filling pot out machine

A technology of sliding machine and stuffing pot, which is applied in the field of catering industry appliances to achieve the effect of crispy skin and improvement of insufficient intake of coarse grains and vegetables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

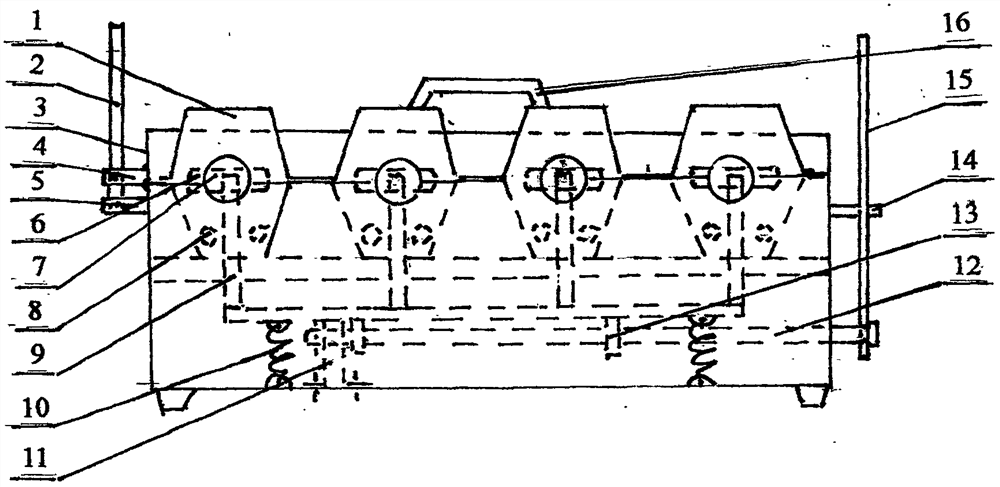

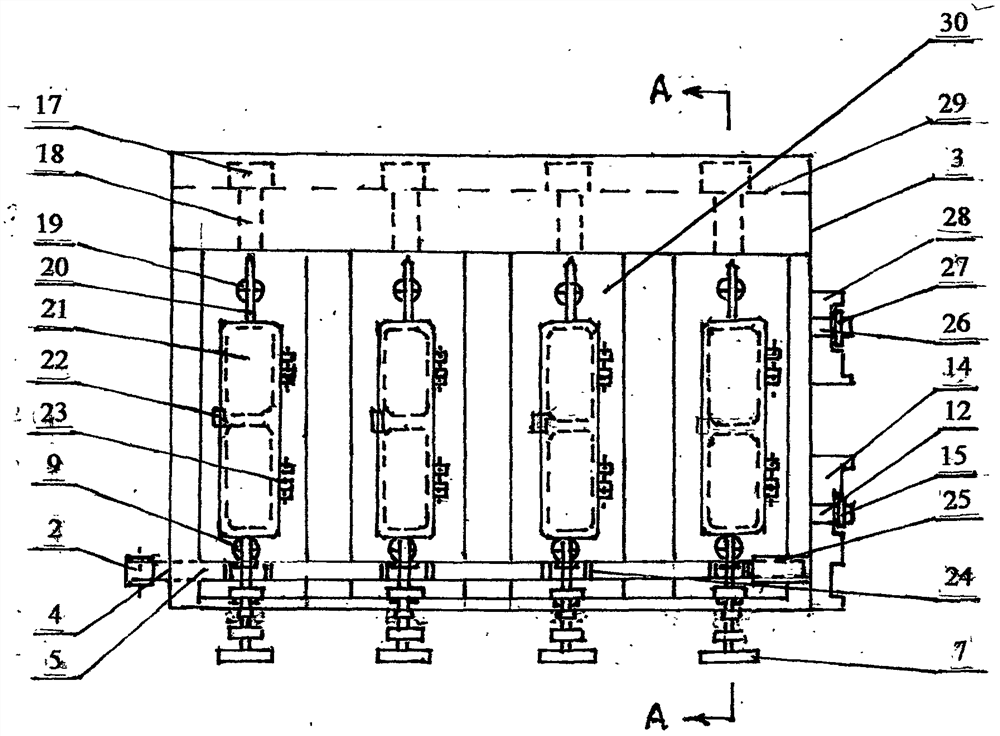

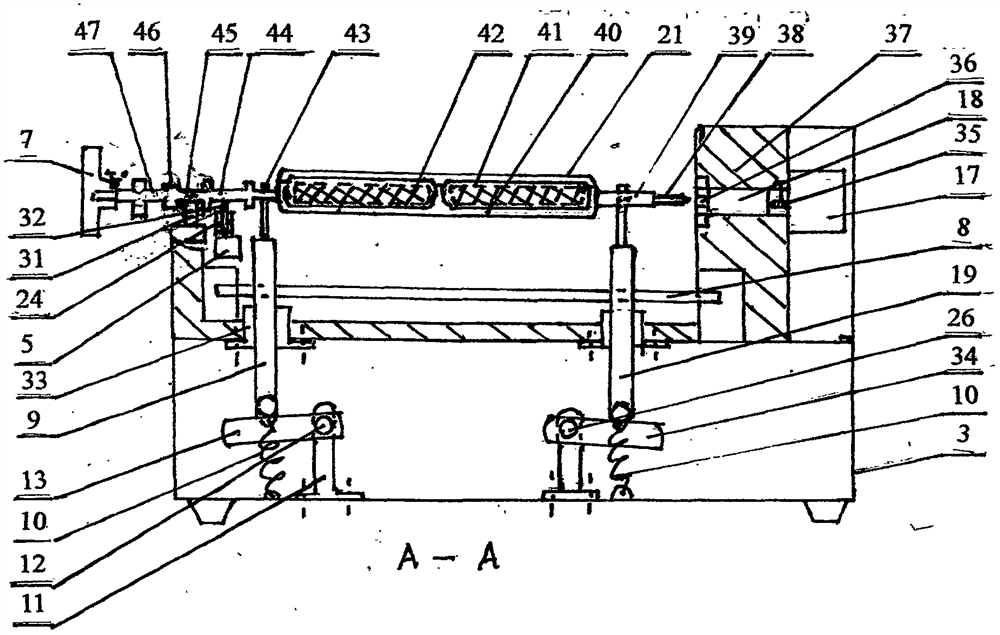

[0006] Specific implementation mode one, (see Figure 1 ~ Figure 3 , Figure 5 to Figure 9) This embodiment consists of machine cover 1, pull push rod 2, casing 3, fixed column 4, movable rod 5, mold assembly 6, hand wheel 7, electric heating tube 8, rear lifting rod assembly 9, extension spring 10 , bracket 11, rear swing column 12, rear swing plate 13, rear limit plate 14, rear pull rod 15, machine cover handle 16, motor 17, shaft sleeve 18, front lifting rod assembly 19, front mold shaft 20, mold cover 21. Spring buckle 22, hinge 23, toggle plate 24, movable rod cover 25, front swing column 26, front pull rod 27, front limit plate 28, motor fixing plate 29, heating zone 30, rear mold shaft support 31 , dialed rod 32, lifting rod cover 33, front swing plate 34, motor shaft 35, square mouth end 36, insulation layer 37, front shaft area 38, front round shaft area 39, mold bottom 40, batter 41, stuffing 42. The rear shaft area 43, the rear mold shaft 44, the swing shaft area ...

specific Embodiment approach 2

[0007] Specific implementation mode two: (see Figure 1 to Figure 9 ) The lower part of the heating zone 30 in this embodiment is provided with a gas burner 48 . Other composition and connection mode are the same as the specific embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com