Soybean coconut cream with no cholesterol and trans-fatty acid and preparation method thereof

A zero-trans and cholesterol technology, applied in the production/processing of edible oil/fat, edible oil/fat, edible oil/fat, etc., can solve the problems of complex raw materials or preparation process, and achieve the improvement of insufficient intake and easy The effect of whipping and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

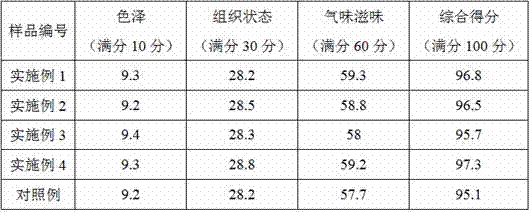

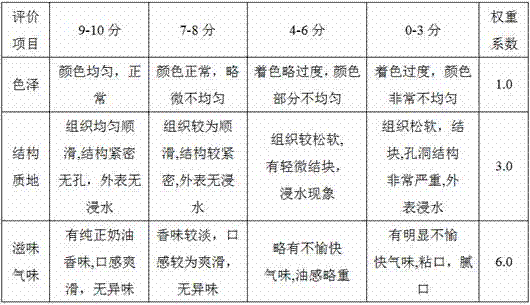

Examples

Embodiment 1

[0036]Soak 16.5 g soybeans for 3 hours in advance, then add water 4 times the volume of soybeans, stir in a mixer at high speed until soybean milk is formed, filter out soybean dregs with gauze, and obtain 50 g soybean milk for later use. Mix soybean milk with 30 g coconut oil, 5 g sucrose, 0.025 g molecularly distilled glyceryl monostearate, 0.025 g soybean lecithin, 0.01 g guar gum, 0.01 g EGCG, 0.005 g VB12, 1 g modified starch, salt Mix 0.3 g, 0.1 g of citric acid, and 0.1 g of vanilla extract, and stir at 70°C and 600 rpm for 30 minutes to make it fully mixed, homogenize twice under a pressure of 20 MPa, and then quickly cool to 15°C and stored at -18°C for 12 h. The frozen cream was thawed to 0°C, whipped at room temperature for 6 min at a speed of 100 rpm, put into a container and placed in a 4°C refrigerator for later use.

Embodiment 2

[0038] Soak 23 g of soybeans for 7 hours in advance, then add 4 times the volume of soybeans in water, stir in a blender at high speed until soybean milk is formed, filter out the soybean dregs with gauze, and obtain 70 g of soybean milk for later use. Mix soybean milk with 50 g coconut oil, 8 g sucrose, 0.4 g molecularly distilled glyceryl monostearate, 0.4 g lecithin, 0.5 g guar gum, 0.03 g EGCG, 0.01 g VB12, 3 g modified starch, and 0.4 g of salt g, 0.2 g of citric acid, and 0.3 g of vanilla extract were mixed, and stirred at 60°C and 600 rpm for 40 minutes to make them fully mixed, homogenized once under a pressure of 25 MPa, and then rapidly cooled to 15°C and stored at -18°C for 14 h. The frozen cream was thawed to 2°C, whipped at room temperature for 2.5 min at a speed of 200 rpm, put into a container and placed in a 4°C refrigerator for later use.

Embodiment 3

[0040] Soak 20 g of soybeans in advance for 5 hours, then add water 4 times the volume of soybeans, stir in a blender at high speed until soybean milk is formed, filter out soybean dregs with gauze, and obtain 60 g of soybean milk for later use. Soymilk was mixed with 40 g coconut oil, 6 g sucrose, 0.4 g salt, 0.2 g molecularly distilled glyceryl monostearate, 0.2 g lecithin, 0.3 g guar gum, 0.02 g EGCG, 0.008 g VB12, and Stir at 80°C and 700 rpm for 30 min to make it fully mixed, homogenize twice under a pressure of 5 MPa, then quickly cool to 15°C, and store at -18°C for 12 h. The frozen cream was thawed to 0°C, whipped at room temperature for 2 min at a speed of 170 rpm, put into a container and placed in a 4°C refrigerator for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com