A Self-limiting Mechanism for Helicopter Tail Fairing

A technology of fairings and helicopters, which is applied in the direction of rotorcraft, motor vehicles, aircraft parts, etc. It can solve the problems of limited opening methods, low work efficiency, and insufficient safety, and achieves rapid opening/closing, simple structure, and low weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

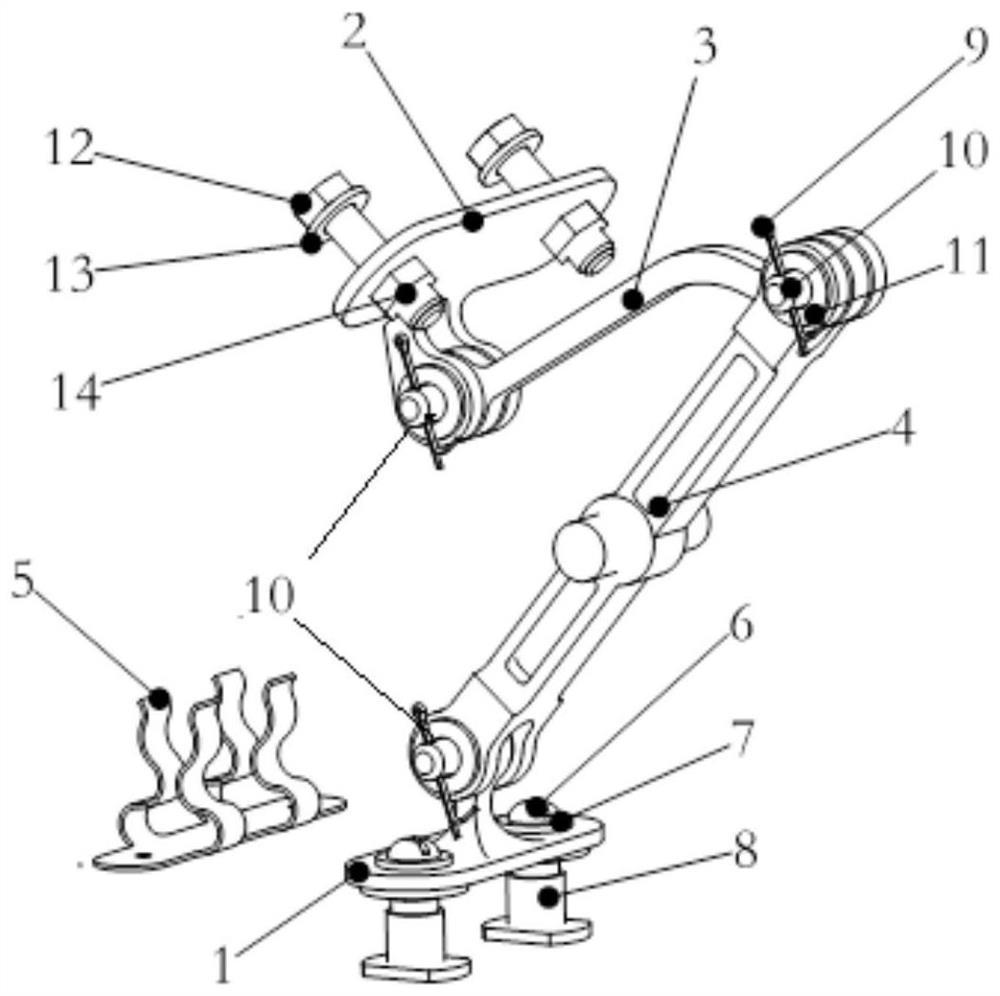

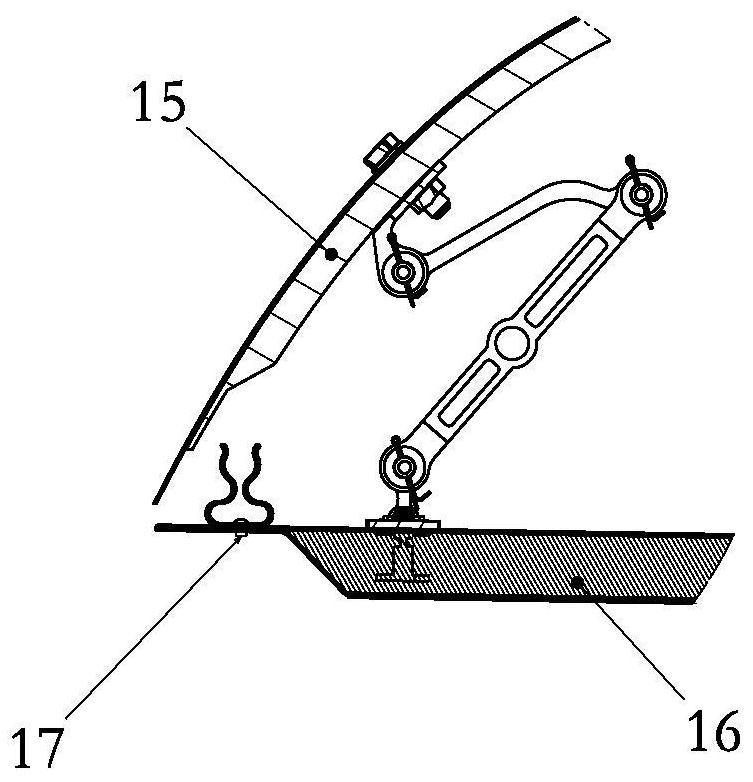

[0016] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing, please refer to Figure 1 to Figure 5 .

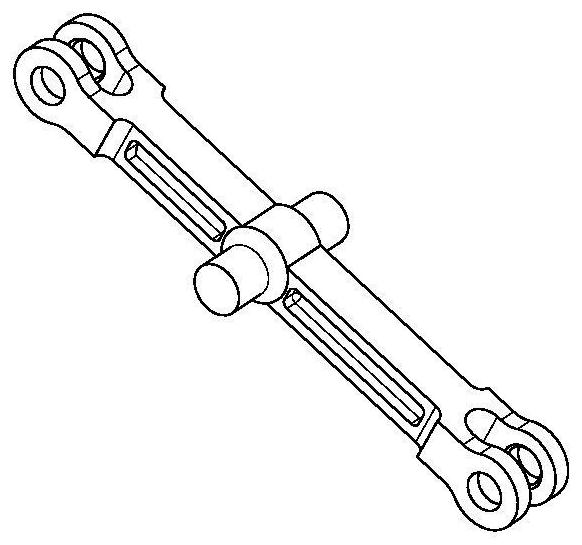

[0017] The self-limiting mechanism of the present invention includes: an upper support 2, a lower support 1, a connecting rod 3, a limit connecting rod 4, a hoop 5, bolts, nuts, washers and other parts. Among them, the connecting rod 3 is a single fork lug structure, the upper support 2, the lower support 1 and the limit connecting rod 4 are double fork lug structures, and the two sides of the limit connecting rod 4 are designed with circular protrusions corresponding to the inner shape of the clamp. tower.

[0018] When assembling, a movement mechanism is formed by connecting the two supports through the connecting rod 3, the limit connecting rod 4 and the shaft pin 10, and the upper support 2 is connected to the fairing 15 through bolts 12, nuts 14 and washers 13, The lower support 1 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com