Turbine shaft

A technology of turbine shaft and cavity, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., and can solve problems such as affecting efficiency and service life, and excessive heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

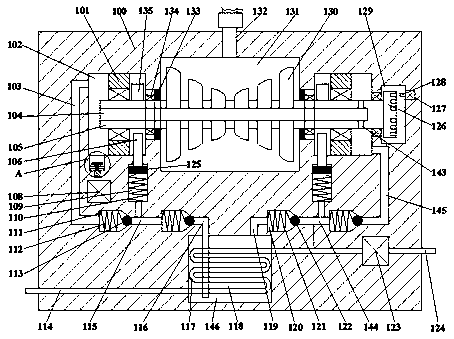

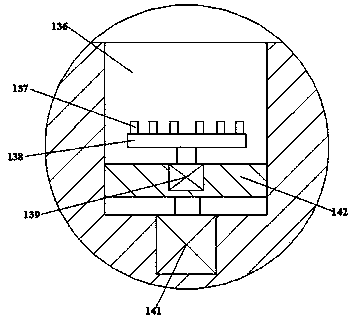

[0012] Such as figure 1 with figure 2 As shown, a turboshaft of the present invention includes a fuselage 100 and a first cavity 131 disposed in the fuselage 100, and a symmetrical second cavity 102 is provided at the left and right ends of the first cavity 131. , the right end of the second cavity 102 is provided with a third cavity 129, the first cavity 131 is rotated and connected with a turbine shaft 105 extending left and right, and the left and right ends of the turbine shaft 105 extend into the second cavity. In the cavity 102, the turbine shaft 105 is penetrated with a cooling oil flow hole 104 opening to the left, and the second cavity 102 is fixedly connected with a fixed block 101 that is rotatably connected with the turbine shaft 105, so The inner wall between the first cavity 131 and the second cavity 102 is provided with a bearing 134 rotatably connected with the turbine shaft 105, and the end of the bearing 134 close to the first cavity 131 is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com