Press-mounting machine for mounting industrial coupler

A coupler and press-fitting machine technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of resource waste, affecting the long-term use of press-fitting mechanisms, inconvenient parts disassembly and replacement, etc., and achieve the goal of improving press-fitting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

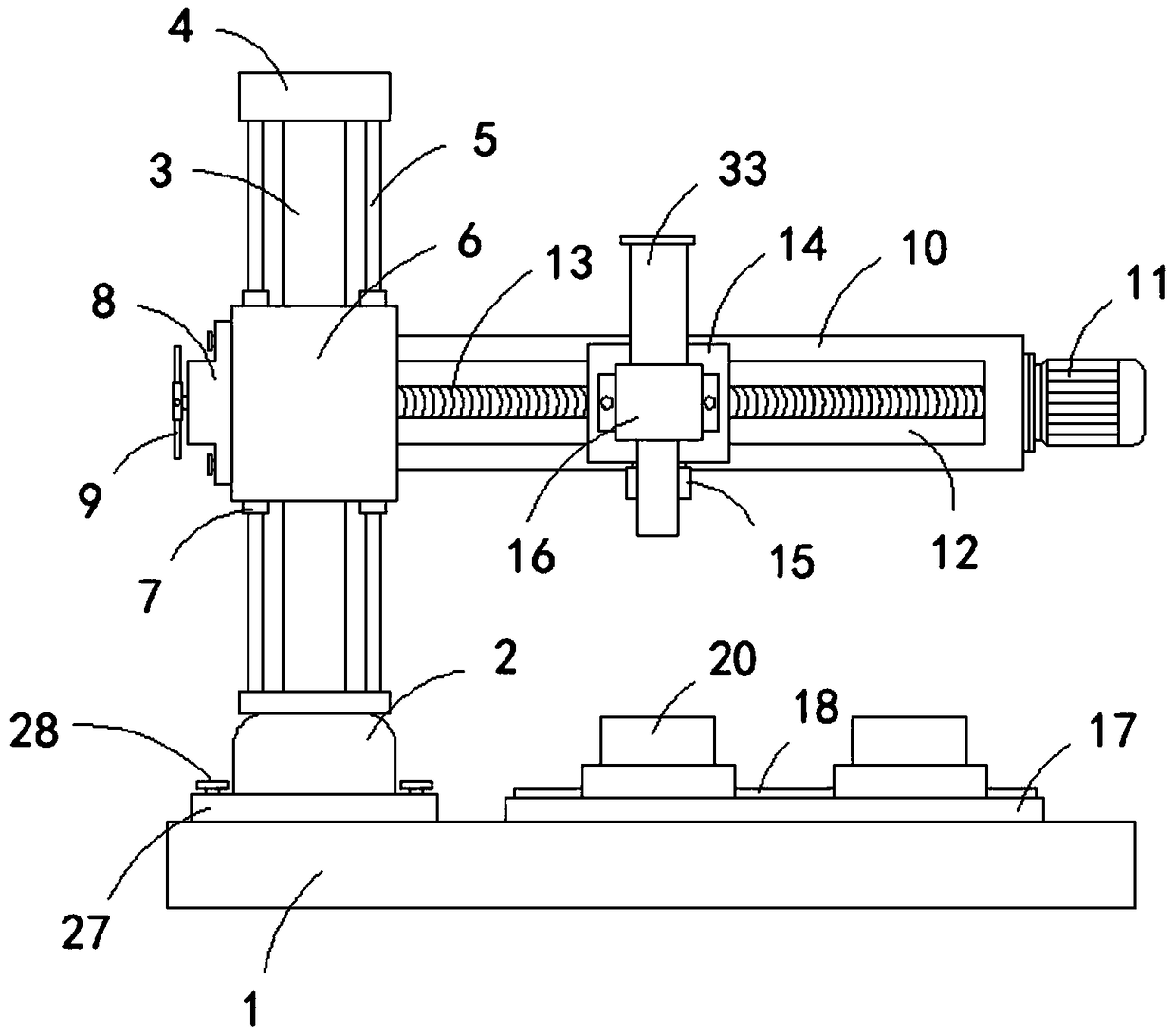

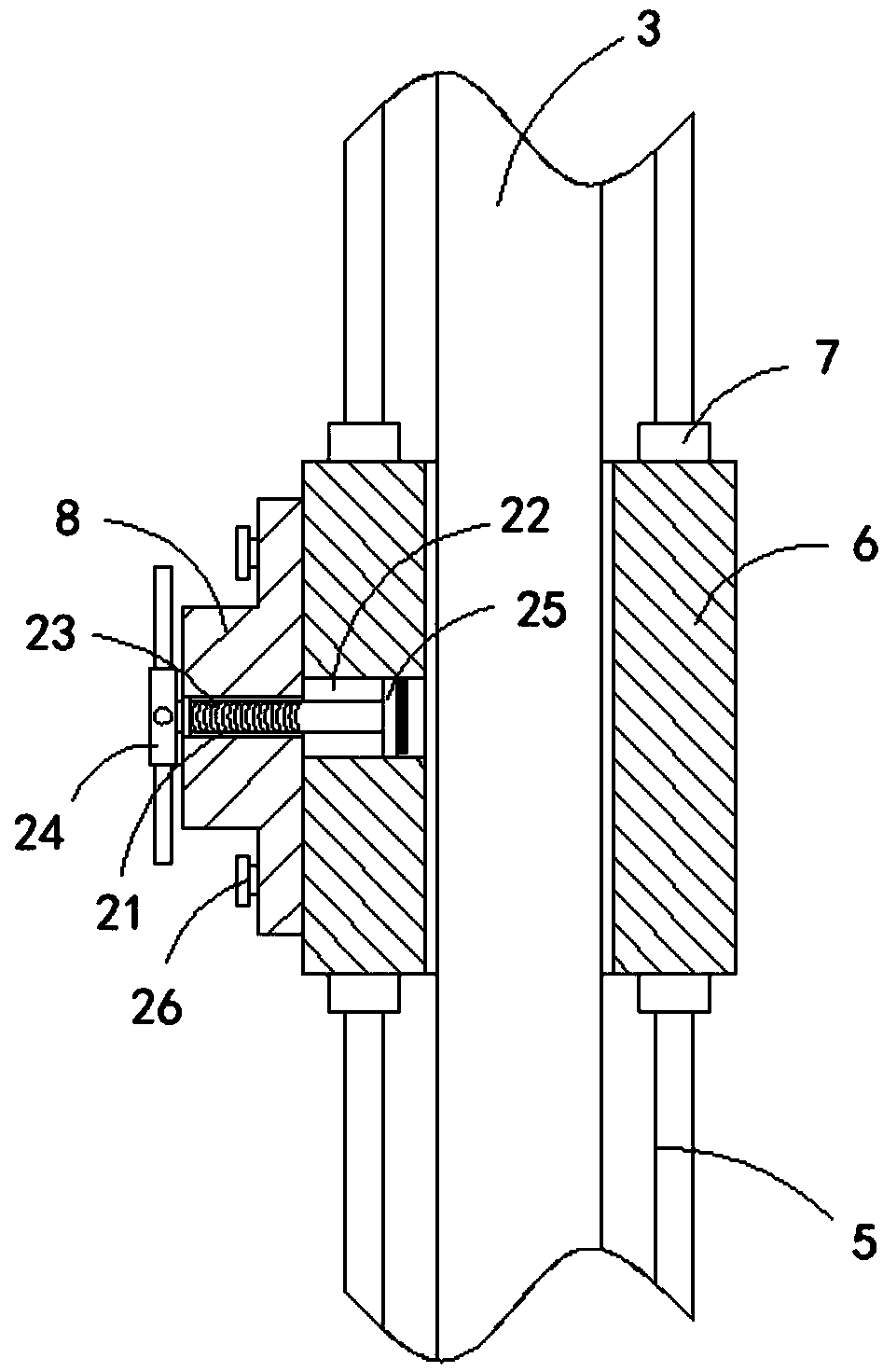

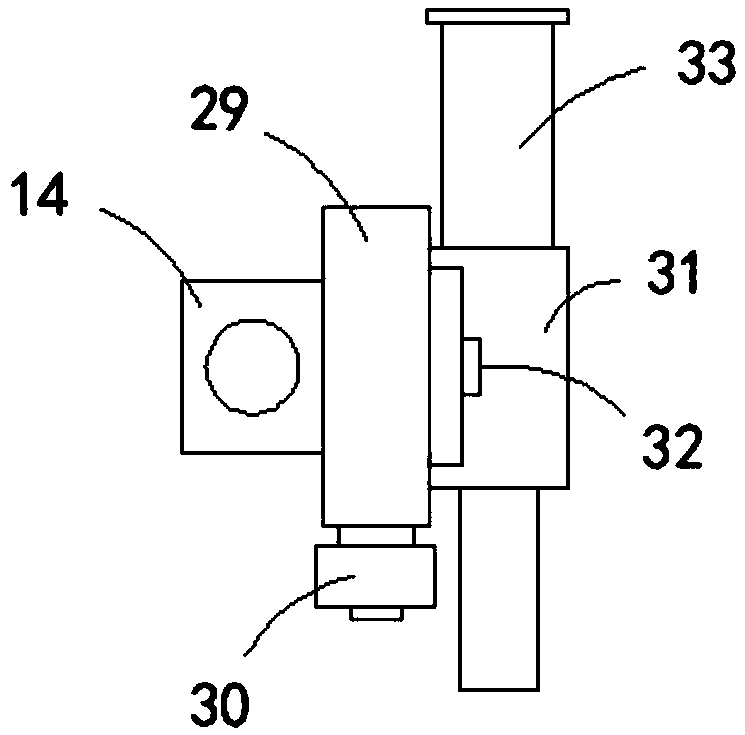

[0022] Such as Figure 1-4 As shown, a press-fitting machine for industrial coupler installation includes a base 1, a mounting base 2 is fixedly connected to the top wall of the base 1, wherein a support 27 is fixedly connected to the bottom wall of the mounting base 2, and the support 27 is fixedly connected with the top wall of the base 1 by a plurality of second bolts 28, which facilitates the disassembly of the mounting seat 2, and is convenient for maintenance and replacement. The top wall of the mounting seat 2 is fixedly connected with a vertical slide bar 3, and the slide bar 3 The end far away from the mounting base 2 is fixedly connected to the limiting top cover 4, and four vertical limiting rods 5 are fixedly connected between the mounting base 2 and the limiting top cover 4, and the limiting rods 5 are correspondingly connected to the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com