A kind of nano-bainite steel with rapid phase transformation and its preparation method

A bainitic steel and nanotechnology, applied in the field of alloys, can solve the problems of long nano-bainite transformation time and unfavorable production, and achieve the effects of shortening preparation time, improving production efficiency, and improving low-temperature isothermal transformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of nano-bainite steel, its content of alloy elements, by mass percentage, is C: 0.51%, Si: 1.72%, Mn: 0.83%, Al: 1.48%, Co: 0.56%, Cr: 0.98%, Mo: 0.25 %, Ni: 0.60%, Nb: 0.04%, and the balance is Fe.

[0029] The preparation method is as follows:

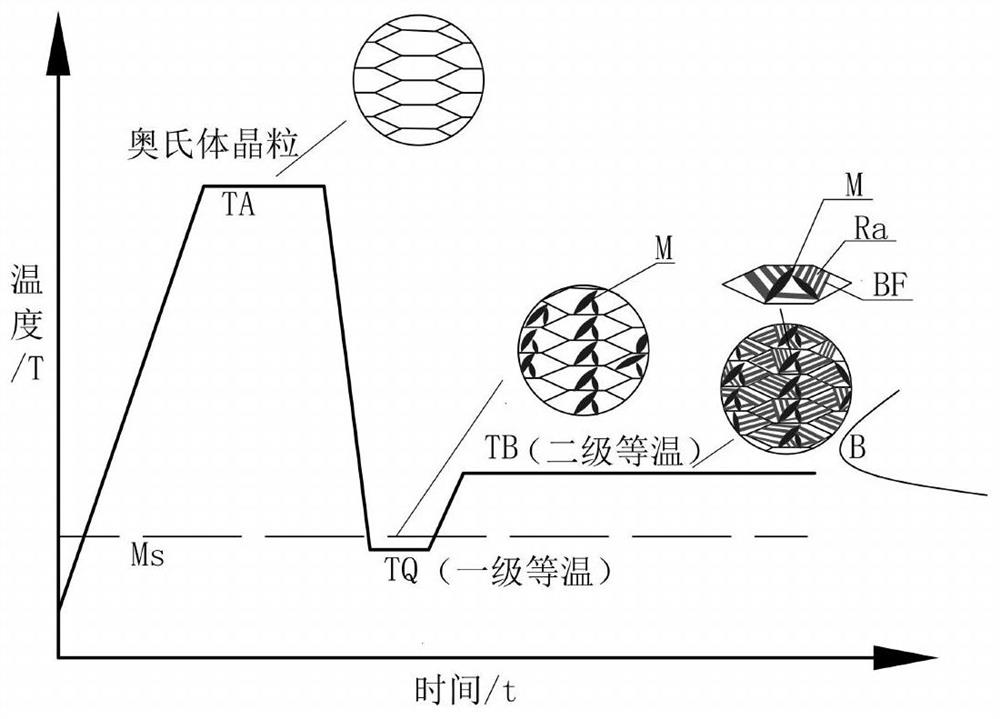

[0030] (1) Heat the billet to 1050°C and keep it warm for 30 minutes to obtain austenite A;

[0031] (2) Austenite A is rapidly cooled to 210°C by salt bath quenching and kept for 30s to obtain a small amount of martensite M;

[0032] (3) Quickly transfer the steel to 280°C, keep it warm for 1 hour, and then air-cool to room temperature to obtain nano-bainitic steel.

[0033] The hardness (HV3) of the finally obtained nano-bainitic steel was 561.

Embodiment 2

[0035] A kind of nano-bainite steel, its content of alloy elements, by mass percentage, is C: 0.51%, Si: 1.72%, Mn: 0.83%, Al: 1.48%, Co: 0.56%, Cr: 0.98%, Mo: 0.25 %, Ni: 0.60%, Nb: 0.04%, and the balance is Fe.

[0036] The preparation method is as follows:

[0037] (1) Heating the billet to 1050°C and keeping it warm for 30 minutes to obtain austenite A;

[0038] (2) Austenite A is rapidly cooled to 220°C by salt bath quenching and kept for 30s to obtain a small amount of martensite M;

[0039] (3) Quickly transfer the steel to 280°C, keep it warm for 1 hour, and then air-cool to room temperature to obtain nano-bainitic steel.

[0040] The hardness (HV3) of the finally obtained nano-bainite steel was 559.

Embodiment 3

[0042] A kind of nano-bainite steel, its content of alloy elements, by mass percentage, is C: 0.51%, Si: 1.72%, Mn: 0.83%, Al: 1.48%, Co: 0.56%, Cr: 0.98%, Mo: 0.25 %, Ni: 0.60%, Nb: 0.04%, and the balance is Fe.

[0043] The preparation method is as follows:

[0044] (1) Heat the billet to 1050°C and keep it warm for 30 minutes to obtain austenite A;

[0045] (2) Austenite A is rapidly cooled to 235°C by salt bath quenching and kept for 30s to obtain a small amount of martensite M;

[0046] (3) Quickly transfer the steel to 280°C, keep it warm for 1 hour, and then air-cool to room temperature to obtain nano-bainitic steel.

[0047] The hardness (HV3) of the final nano-bainitic steel obtained was 544.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com