Sintered neodymium-iron-boron preparation method capable of improving intrinsic coercivity and anticorrosive performance

A technology of intrinsic coercive force and NdFeB, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problem of high corrosion resistance and process requirements, and achieve high amorphous forming ability and intrinsic coercive force The effect of improving and reducing weight loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

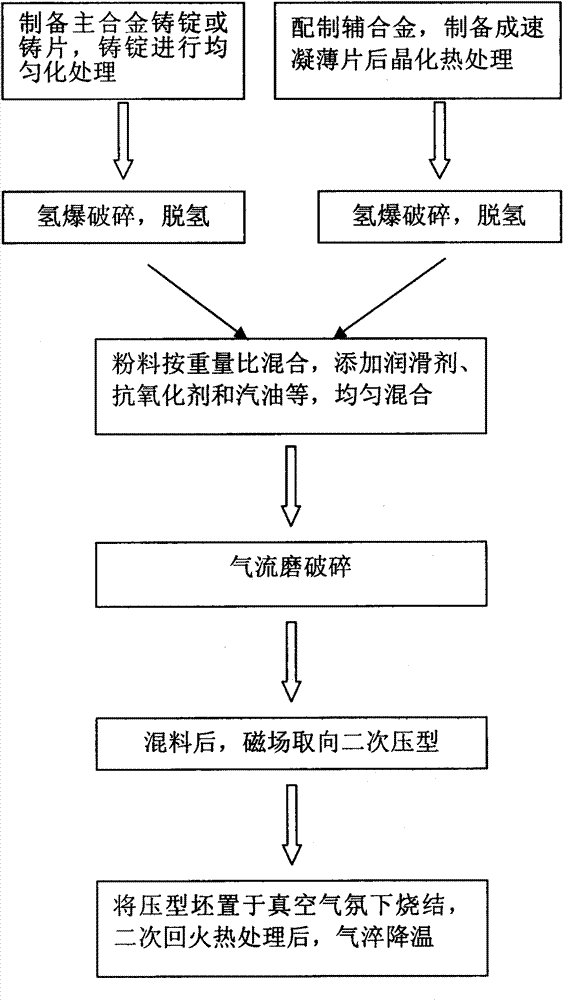

[0019] In conjunction with the accompanying drawings, the present invention improves the intrinsic coercivity and corrosion resistance of the sintered NdFeB preparation method, comprising the following steps:

[0020] Step 1, preparing the main NdFeB alloy, preparing the NdFeB main alloy into alloy ingots or using the quick-setting casting process to prepare cast sheets, and performing homogenization heat treatment on the alloy ingots; homogenizing the heat treatment temperature on the alloy ingots The temperature is 950-1150°C, and the time is 3-20h.

[0021] Step 2, preparation auxiliary alloy, the atomic percentage of auxiliary alloy is (Ce-La-Pr-Nd) 100-x-y-z co x al y m z , where M is one or a mixture of two or more of Ga, Cu, Nb, 20≤x≤30, 5≤y≤15, 0≤z≤5, each rare earth element in the total composition of the auxiliary alloy is hundreds of atoms The content is: Ce: 25-30%; La: 20-25%; Pr: 0-5%; Nd: 5-15%.

[0022] Step 3, smelting the auxiliary alloy to obtain the au...

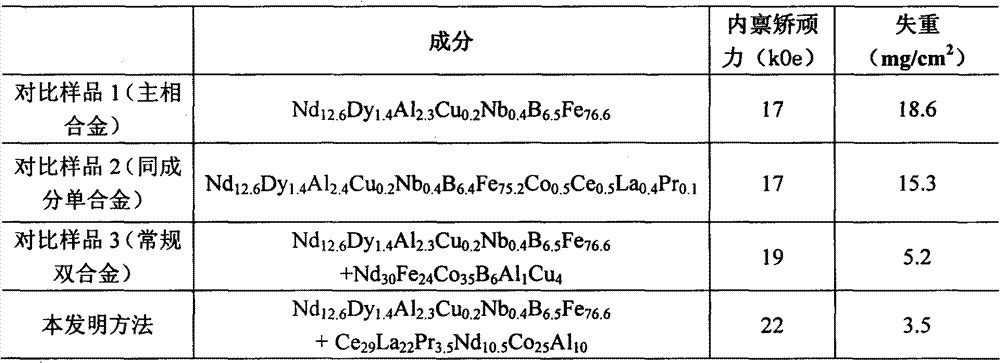

Embodiment 1

[0029] Step 1, preparation of NdFeB main alloy, the atomic ratio of its composition is Nd 12.6 Dy 1.4Al 2.3 Cu 0.2 Nb 0.4 B 6.5 Fe 76.6 , using a water-cooled copper mold to cast the main alloy into an NdFeB alloy ingot, and perform a vacuum heat treatment for homogenizing the composition of the alloy ingot at 1000 ° C for 8 hours.

[0030] Step 2, preparation auxiliary alloy, the atomic percentage of auxiliary alloy is Ce 29 La 22 PR 3.5 Nd 10.5 co 25 Al 10 .

[0031] Step 3: Smelting the auxiliary alloy to obtain auxiliary alloy ingots, preparing quick-setting flakes by using the quick-setting flake preparation process, the roll speed is 40m / s, heat-treating the auxiliary alloy strips at 400°C for 20 minutes in vacuum, and then cooling to room temperature.

[0032] Step 4, performing hydrogen explosion crushing on the main and auxiliary alloys respectively, and performing dehydrogenation treatment at 550° C. for 2 hours.

[0033] Step 5, mix the hydrogen crushed...

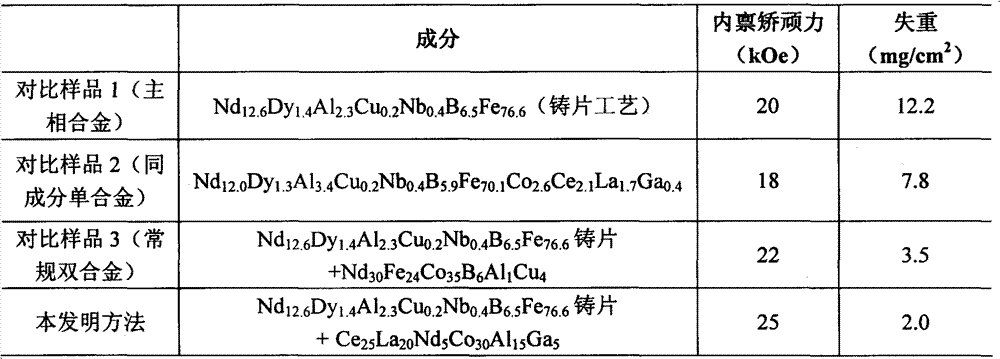

Embodiment 2

[0039] Step 1, preparation of NdFeB main alloy, the atomic ratio of its composition is Nd 12.6 Dy 1.4 Al 2.3 Cu 0.2 Nb 0.4 B 6.5 Fe 76.6 , using the quick-setting casting process to cast the main alloy into NdFeB alloy castings.

[0040] Step 2, preparation auxiliary alloy, the atomic percentage of auxiliary alloy is Ce 25 La 20 Nd 5 co 30 Al 15 Ga 5 .

[0041] Step 3: Melt the auxiliary alloy to obtain auxiliary alloy ingots, prepare quick-setting flakes by using the quick-setting flake preparation process, the roll speed is 5m / s, heat-treat the auxiliary alloy flakes at 200°C for 1 hour in vacuum, and cool to room temperature.

[0042] Step 4, performing hydrogen explosion crushing on the main and auxiliary alloys respectively, and performing dehydrogenation treatment at 500° C. for 4 hours.

[0043] Step 5. Mix the hydrogen crushed powder of the main and auxiliary alloys in a weight ratio of 88:12, and add 0.05% lubricant, 1% antioxidant, and 1% gasoline in a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com