System for defect inspection and method for defect inspection

A defect inspection and object technology, applied in the field of defect inspection systems, which can solve problems such as difficulty in identifying defect categories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

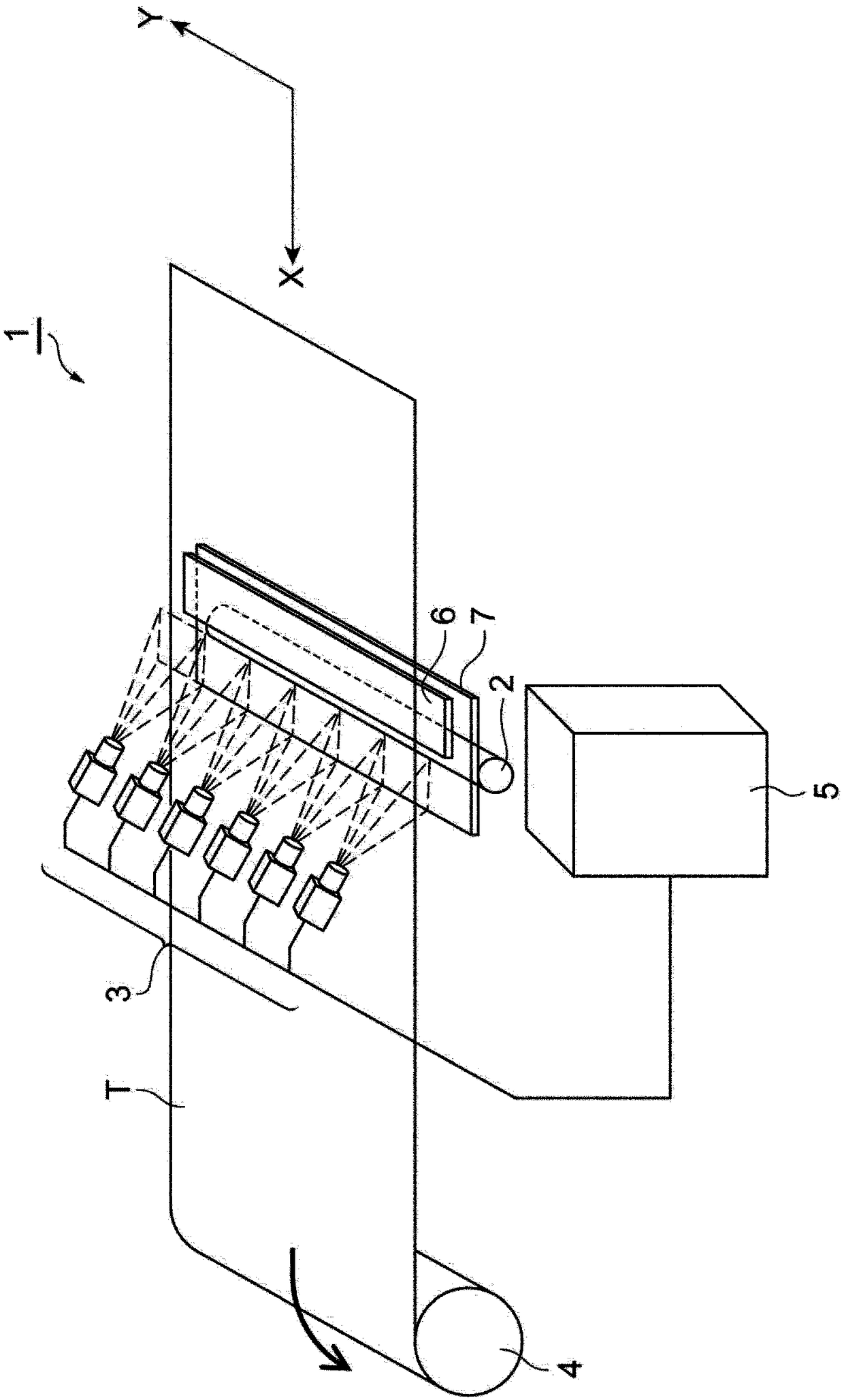

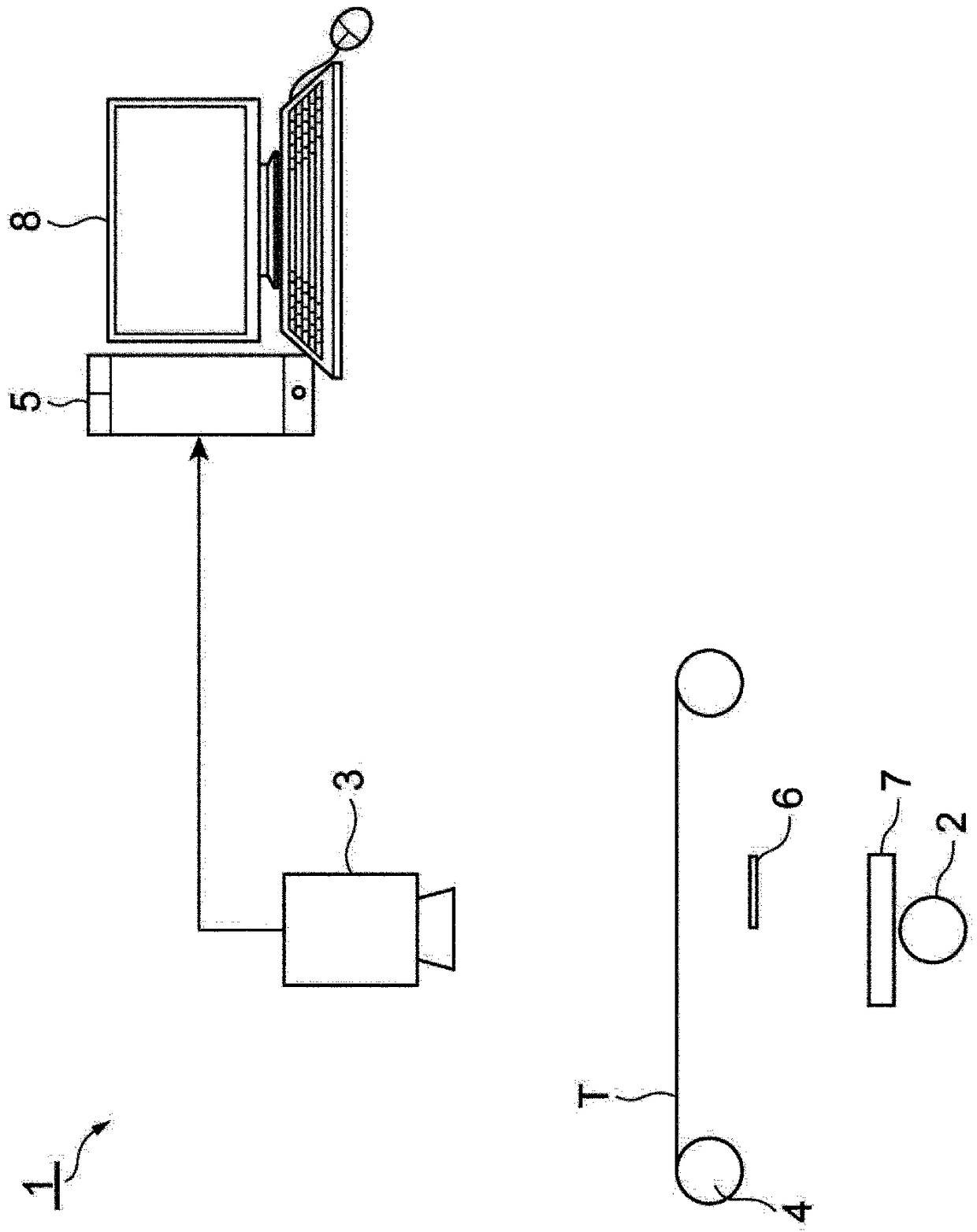

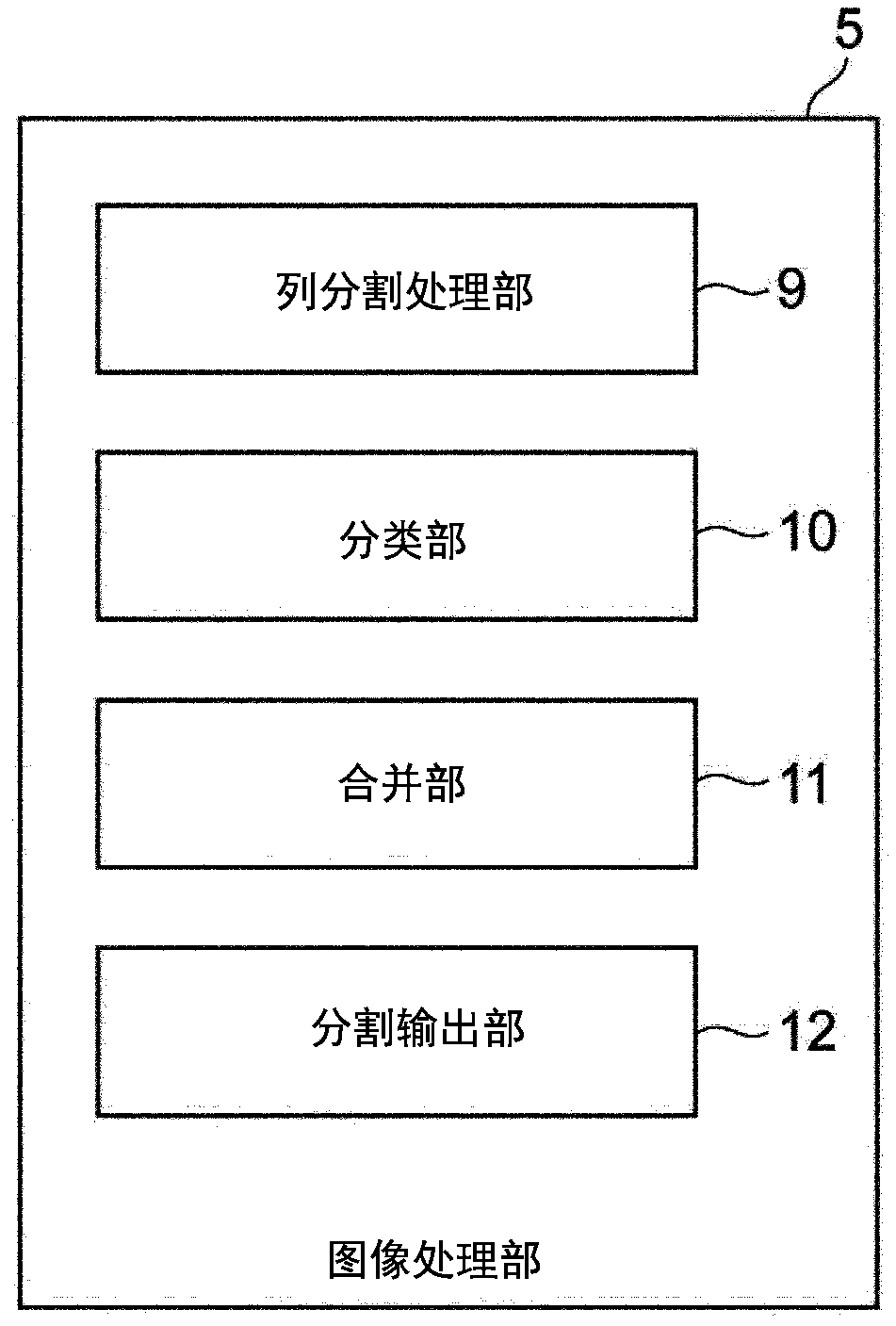

[0048]Hereinafter, preferred embodiments of the defect inspection system and defect inspection method of the present invention will be described in detail with reference to the drawings. Such as figure 1 and figure 2 As shown, the defect inspection system 1 according to the embodiment of the present invention includes a light source 2 , an imaging unit 3 , a transport unit 4 , an image processing unit 5 , a light shield 6 , a collimated light lens 7 , and an analysis unit 8 . The defect inspection system of this embodiment uses optical films such as polarizing films and retardation films, laminated films used for battery separators, and the like as inspection objects T, and detects defects in the inspection objects T. The inspection object T extends along the conveyance direction X of the conveyance unit 4 , and has a predetermined width in a width direction Y perpendicular to the conveyance direction X. Defects generated in the inspection object T refer to a state differen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap