Shale cracking device using carbon dioxide in different phases and experiment method

A carbon dioxide and shale technology, applied in measurement devices, material inspection products, instruments, etc., can solve the problems of less development of experimental devices and insufficient research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

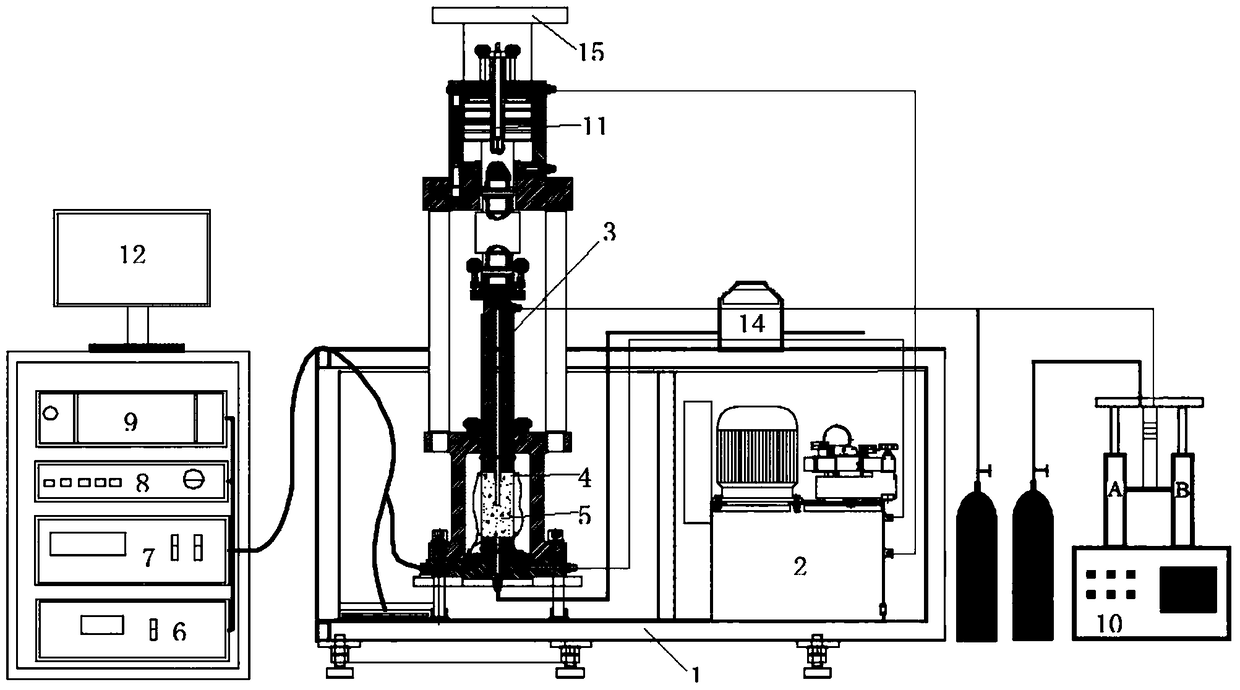

[0046] like figure 1 As shown, the device consists of a constant temperature oil bath, a conventional three-axis loading system, an acoustic emission monitoring system, CO 2 Composed of fracturing system, control system, deformation test system and gas flow meter.

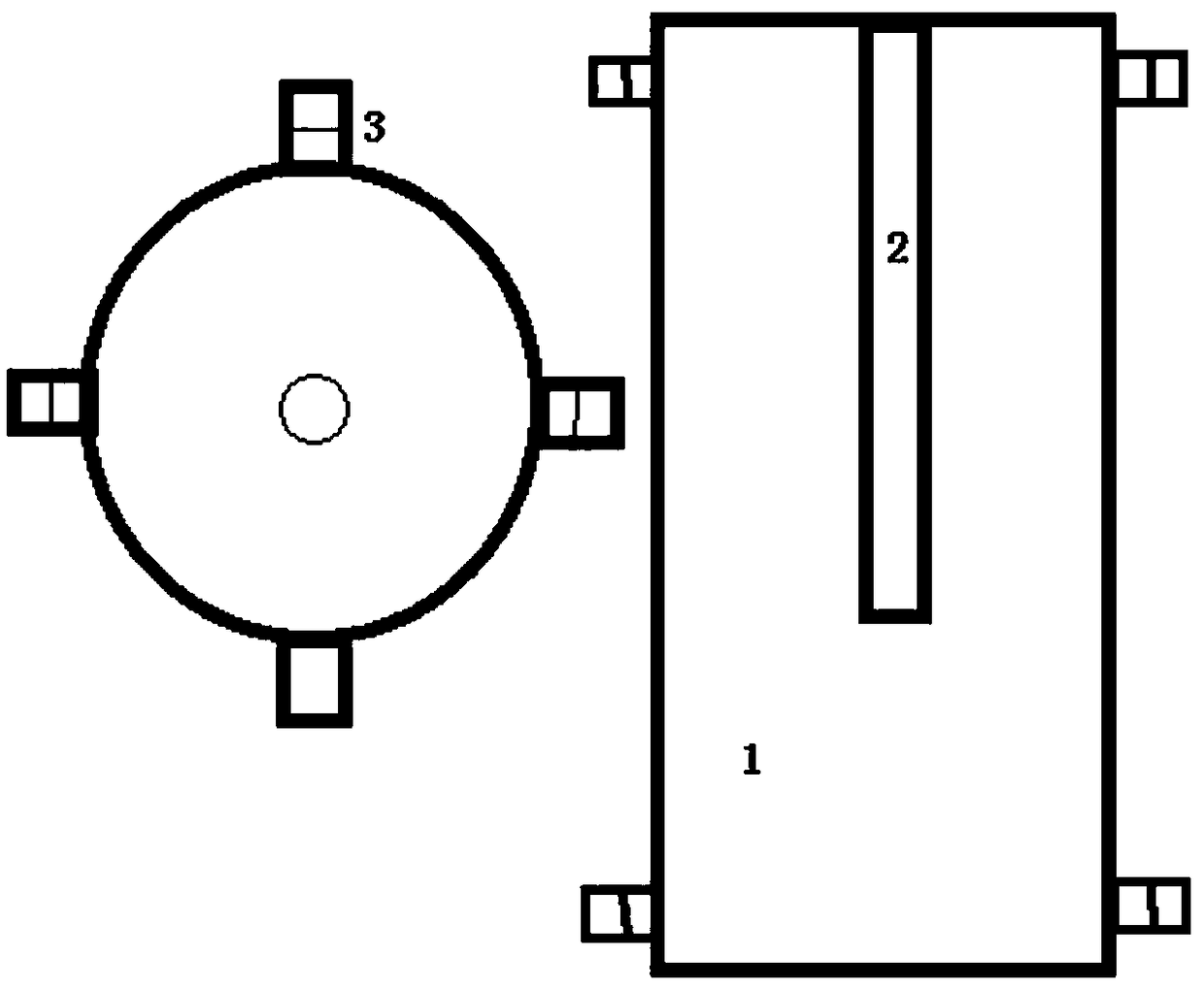

[0047] In this embodiment, the carbon dioxide fracturing shale acoustic emission sensor arrangement figure 2 As shown, in order to achieve a good experimental effect, a total of 8 sensors are arranged, and 4 acoustic emission sensors are evenly arranged on the upper and lower ends of the shale specimen, and the acoustic emission sensors are pasted on the surface of the heat shrinkable tube. figure 2 A medium shale test piece (1), a fracturing hole (2), and an acoustic emission sensor (3). The number of channels of the acoustic emission instrument is 16, 18-bit A / D, frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com