Nuclear power plant radioactive waste gas treatment system water sealing device

A water sealing device and exhaust gas treatment technology, which is applied in the field of nuclear power plants, can solve the problems that the operating flow cannot meet the design requirements, the system cannot be put into operation, and the radioactive waste gas treatment system cannot form a closed system, so as to reduce the risk of weld defects and improve the process structure. Simple, effect of reducing the number of openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The water sealing device of the nuclear power plant radioactive waste gas treatment system provided by the present invention will be further described in detail below with reference to the drawings and embodiments.

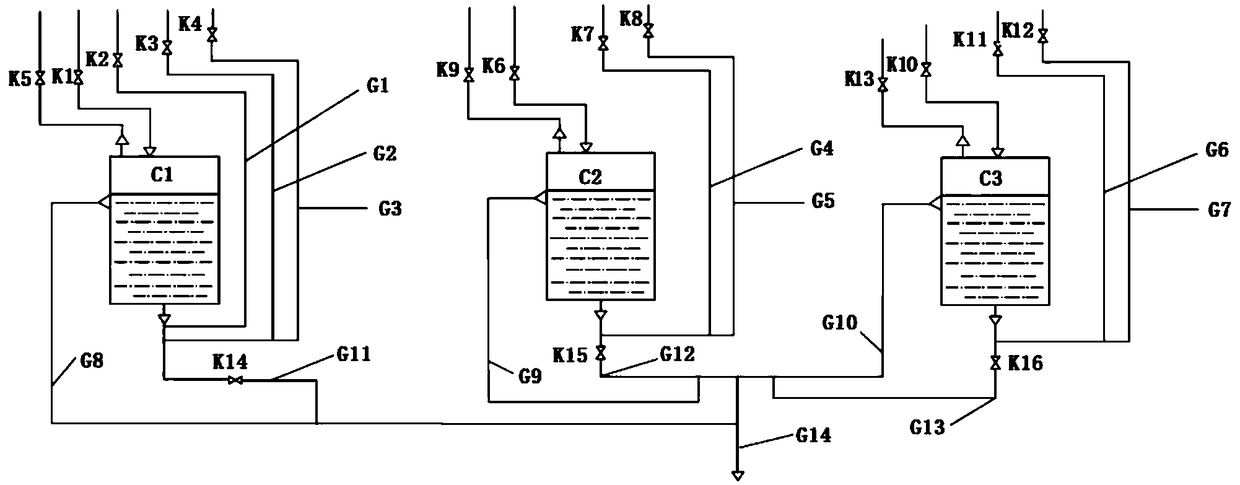

[0028] Such as figure 1 As shown, a water sealing device for a radioactive waste gas treatment system of a nuclear power plant provided by the present invention includes a first water sealing tank C1, a second water sealing tank C2, a third water sealing tank C3, and pipelines connected thereto, valve.

[0029] The water replenishment port at the top of the first water seal tank C1 is connected to the first water replenishment pipeline, the first water replenishment pipeline is provided with a first water replenishment pipeline valve K1, and the exhaust port at the top of the first water seal tank C1 is connected to the exhaust pipeline of the first water seal tank , the first water seal tank exhaust pipeline is provided with the first water seal tank exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com