Solenoid valve control method and device

A control method and solenoid valve technology, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as the inability to fundamentally guarantee the driving safety of vehicles and the inability to guarantee the driving safety of automatic transmission vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

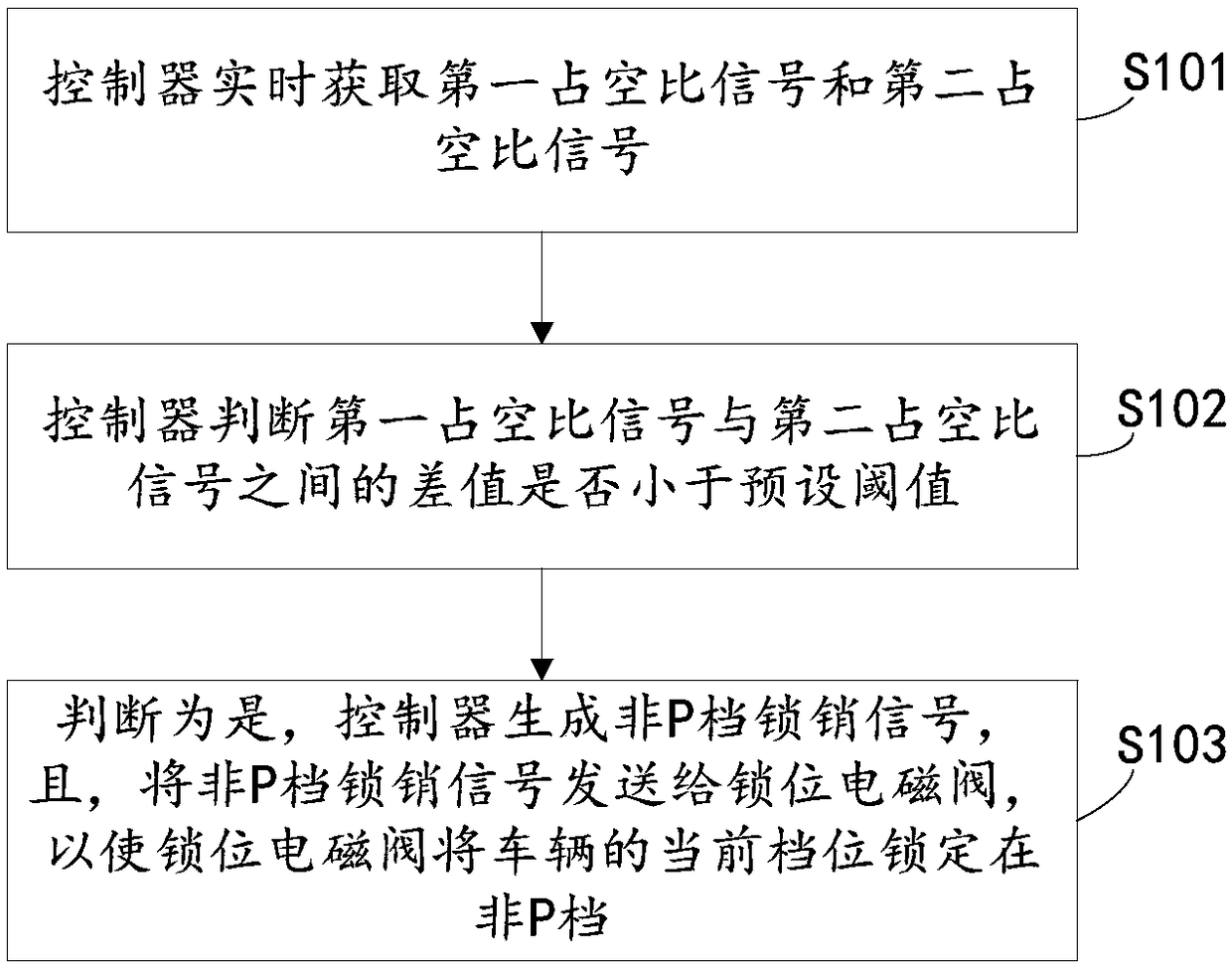

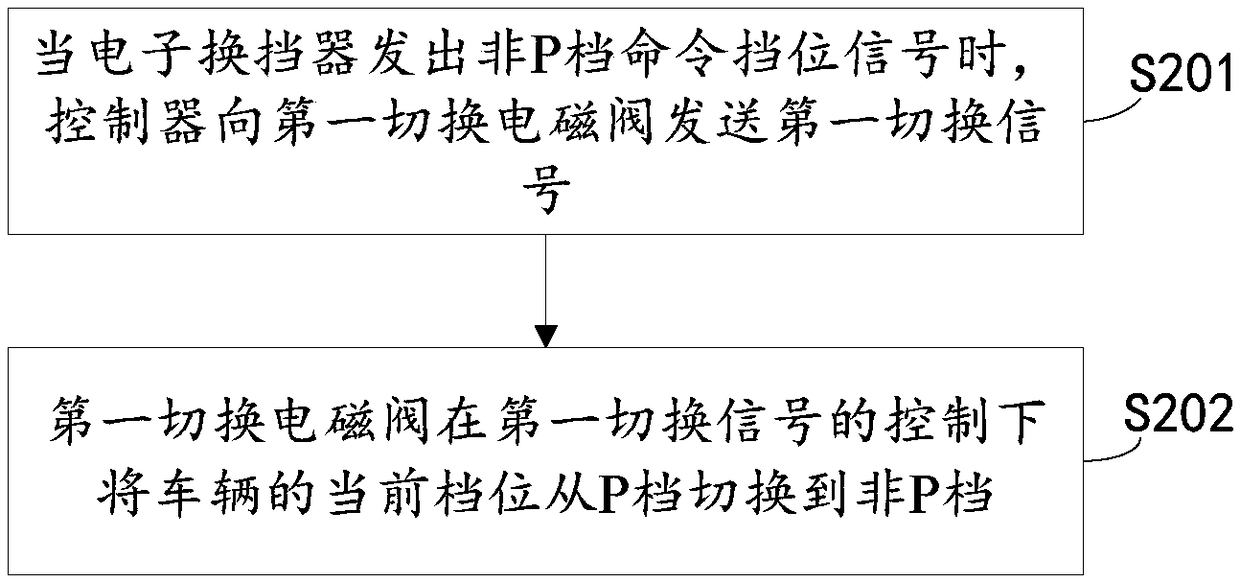

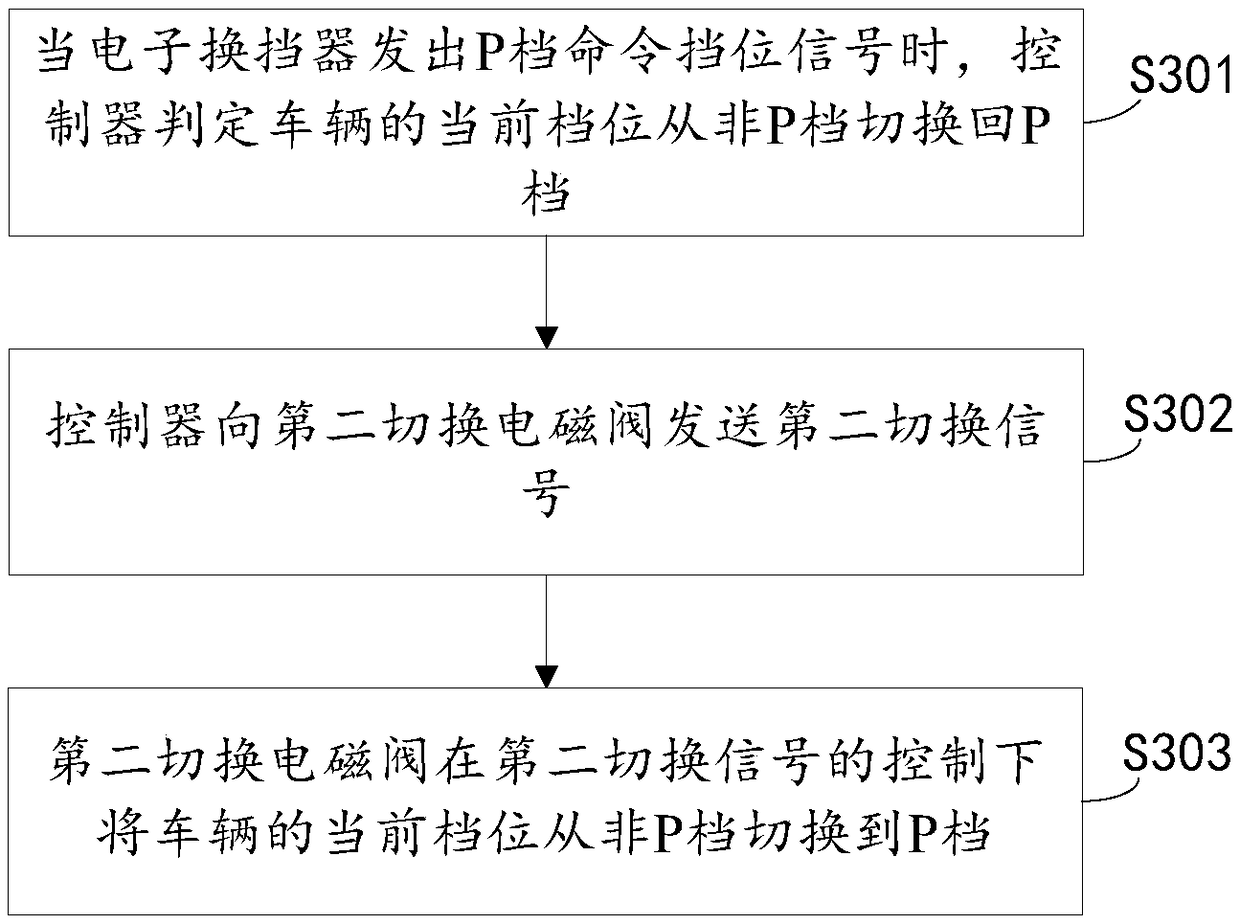

[0045] see figure 1 , figure 2 with image 3 , the solenoid valve control method proposed in this embodiment specifically includes the following steps:

[0046] Step S101: The controller obtains the first duty ratio signal and the second duty ratio signal in real time, wherein the first duty ratio signal is the duty ratio value corresponding to the non-P gear, and the controller obtains the real-time value from the P gear switch position sensor The duty ratio signal is a second duty ratio signal.

[0047]Usually, the default initial gear position of the vehicle is the P gear, that is, under normal circumstances, the duty cycle is equal to about 10% in the initial state. In the case of a fault, the duty cycle may be equal to any value between 0% and 100% in the initial state. After the vehicle is started, if the driver switches the shift lever to non-P, the transmission control unit will control the first switching solenoid valve, so that the relevant hydraulic oil circuit...

Embodiment 2

[0073] see Figure 4 , the present embodiment provides a solenoid valve control device comprising:

[0074] The duty ratio acquisition module 1 is used for the controller to obtain the first duty ratio signal and the second duty ratio signal in real time, wherein the first duty ratio signal is the duty ratio value corresponding to the non-P gear, and the controller starts from the P gear The duty ratio signal acquired by the switch position sensor in real time is the second duty ratio signal;

[0075] Judging module 2, used for the controller to judge whether the difference between the first duty ratio signal and the second duty ratio signal is greater than a preset threshold;

[0076] The locking module 3 is configured to determine yes, the controller generates a non-P gear lock pin signal, and sends the non-P gear lock pin signal to the lock position solenoid valve, so that the lock position solenoid valve locks the current gear position of the vehicle at Non-P file.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com