Contact lens disinfection box

A technology for contact lenses and sterilization boxes, applied in the field of sterilization boxes, can solve the problems of time limitation, inability to realize aseptic operation, inability to guarantee antivirus and sterilization, etc., to avoid inconvenience and unsanitary, long service life and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

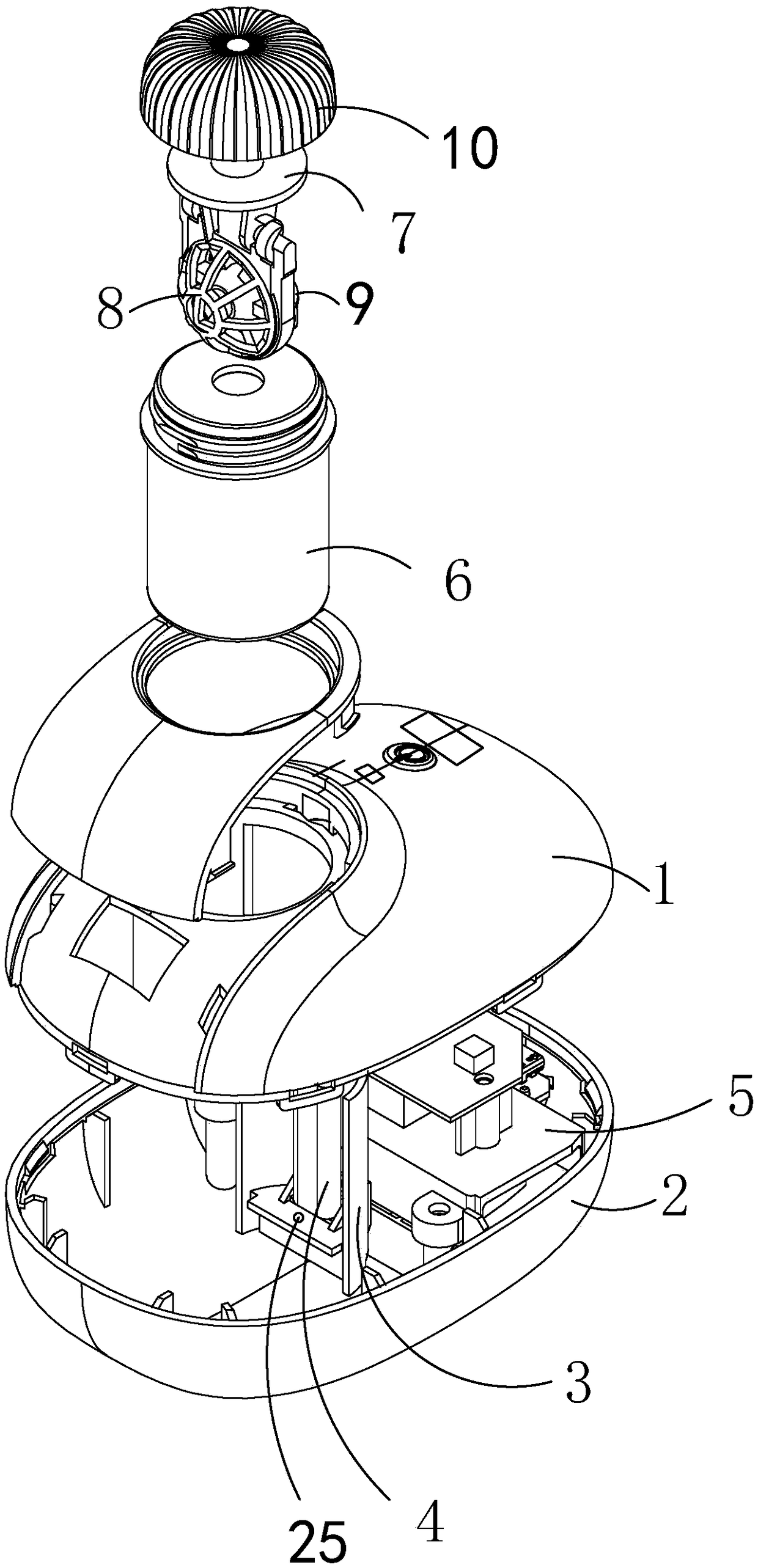

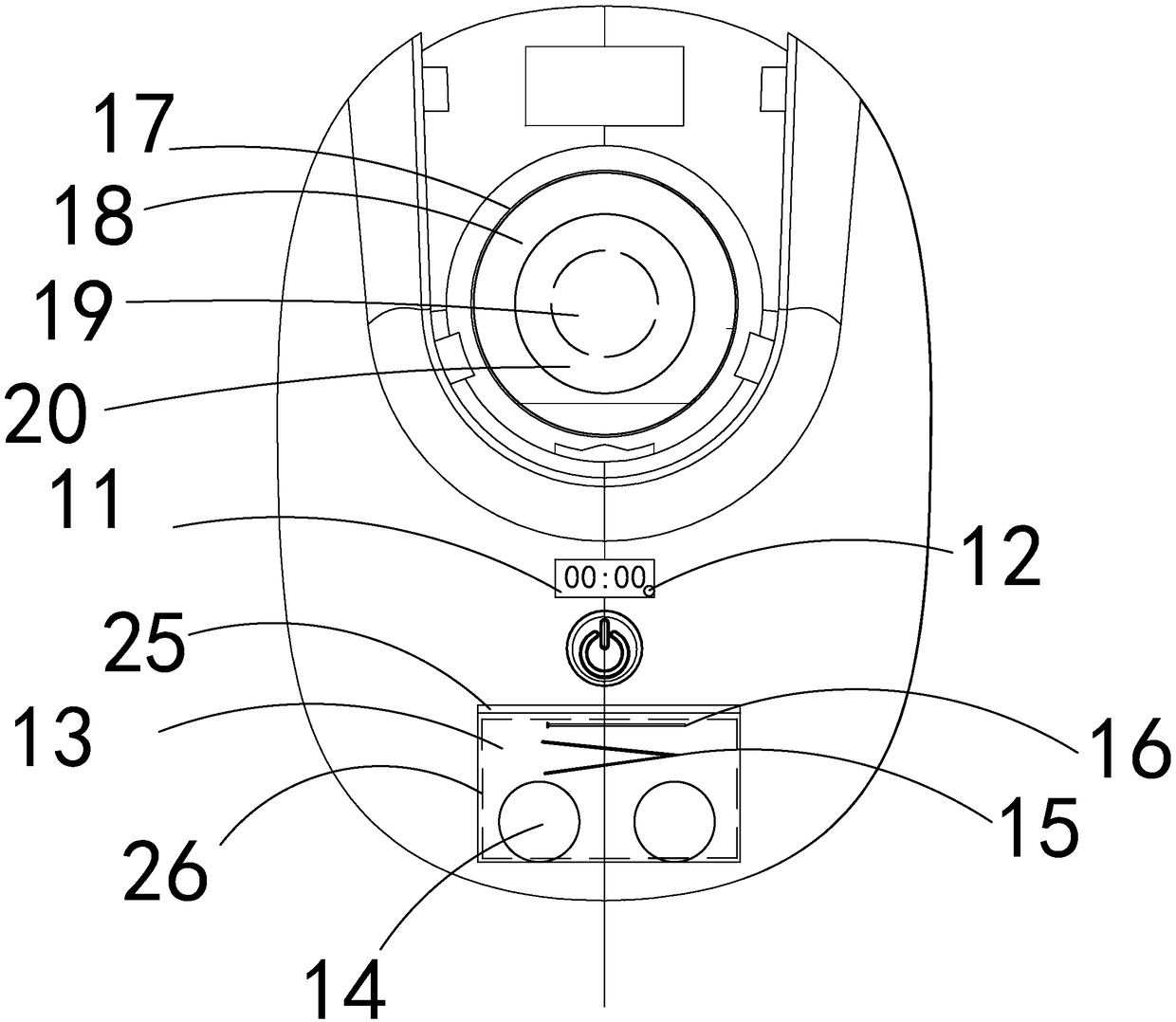

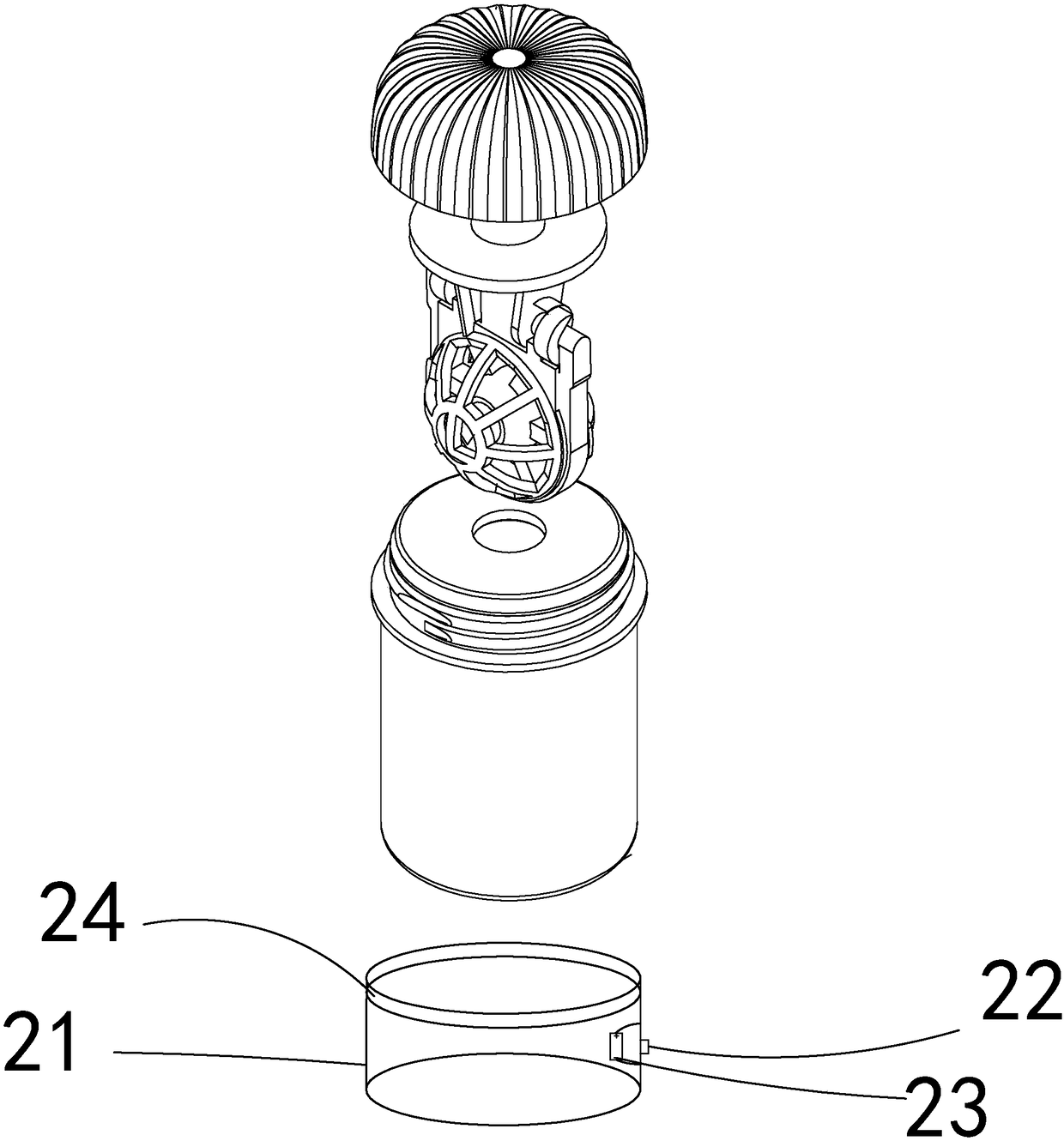

[0017] see details figure 1 , figure 2 with image 3 , a contact lens disinfection box, including a box body composed of a base 2 and an upper cover 1, the box body is mostly made of plastic, has the advantages of durability, waterproof, light weight and so on. The inside of the box body is provided with a transparent bottle for placing contact lenses. The bottle for placing contact lenses includes a bottle body 6, a bottle cap 10 and a contact lens cleaning frame 7. The upper end of the bottle body is provided with a ring-shaped protruding buckle. The inside of the bottle cap 10 is connected with the contact lens cleaning frame 7 , and the bottle cap 10 is fixed by thread sealing with the upper end of the bottle body 6 . The upper cover 1 is provided with a circular opening for placing a contact lens bottle, and the circular opening is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com