Method for operating a condenser tumble-dryer comprising a thermal pump and a condenser tumble dryer that is suitable for said method

An operation method and technology of a clothes dryer, which can be applied to household clothes dryers, textile and paper making, washing devices, etc., can solve the problems of heat loss, energy consumption of drying treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

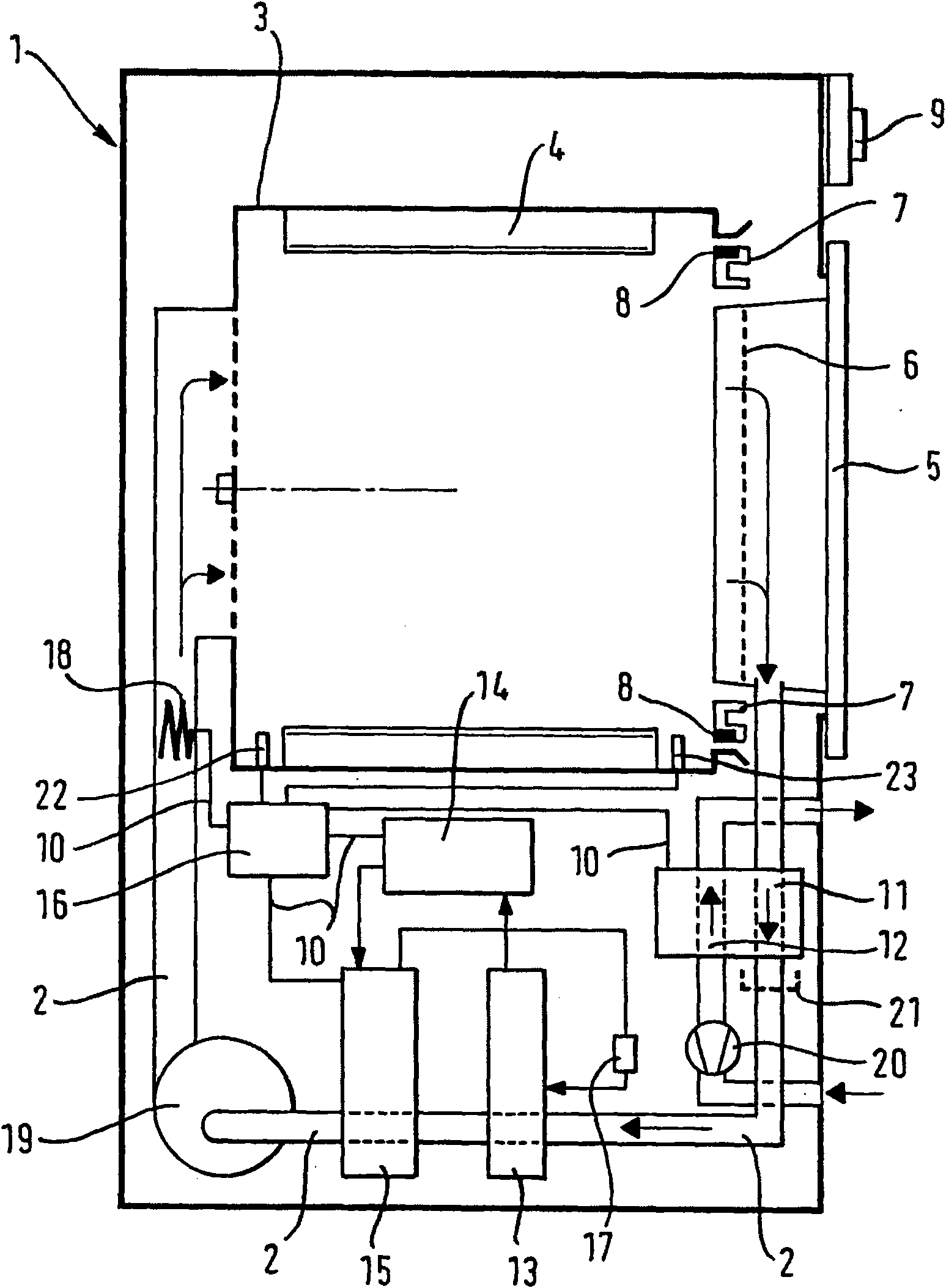

[0029] Such as figure 1The clothes dryer shown comprises a drum rotatable about a horizontal axis, said drum serving as a drying chamber 3 in which an agitator 4 is mounted to move the laundry during the rotation of the drum. Process air is guided by means of a fan 19 over the heating element 18, through the drum 3, the heat exchangers 11, 12 and the heat pumps 13, 14, 15 in the air duct 2 in a closed circuit (process air circuit 2). After passing through the drum 3, the hydrated, hot process air is cooled and, after condensation of the moisture contained in the process air, the process air is reheated. In this case, the air heated by the heating element 18 is guided into the drum 3 from the rear, ie from the side of the drum 3 opposite the dryer door 5, through the perforated bottom, into contact with the laundry to be dried, And flow through the filling port of the drum 3 to reach the lint filter 6 in the dryer door 5 closing the filling port. The flow of air is then turne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com