3D printer convenient to detach

A technology for easy disassembly of 3D printers, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve problems such as troublesome disassembly of 3D printers, achieve simple disassembly, tight fixation, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

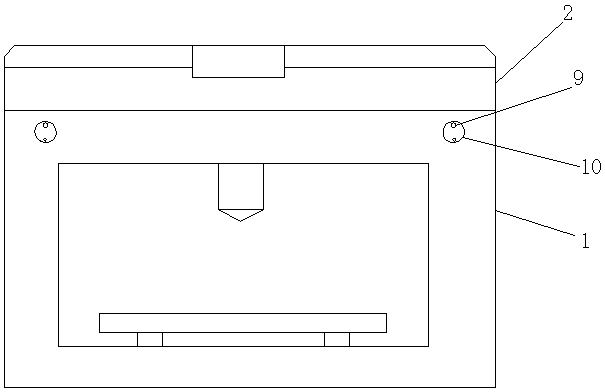

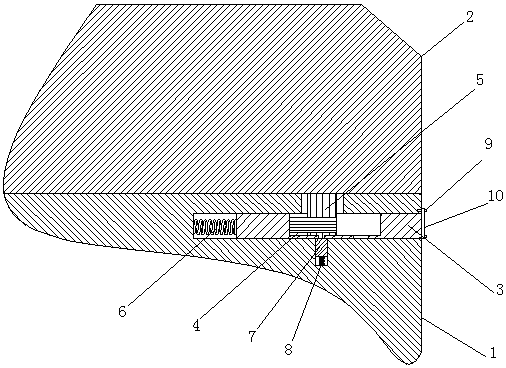

[0018] Examples, see Figure 1-2 , a 3D printer that is easy to disassemble, including a printer body, the printer body includes a support shell 1, a control box 2, the back of the support shell 1 is hinged to the control box 2, and the front top of the support shell 1 has a moving hole, and the movement inside the hole The moving block 3 is connected, the moving block is a cylindrical structure, the middle part of the moving block is provided with a rectangular groove, the middle part of the moving block 3 is fixed with a lock cylinder 4, the bottom of the control box 2 is fixed with a lock cylinder 5, and the gap between the moving block 3 and the supporting shell 1 A return spring 6 is fixed, a limit hole is opened at the bottom of the moving hole, and a limit block 7 is movably connected in the limit hole, and a pop-up spring 8 is fixed between the bottom of the limit block 7 and the support shell 1, and the movement hole is circular in design. The moving block 3 is closel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com