Method for leveling end surface of probe of three-coordinate measuring device based on point diffraction interferometer

A technology of three-coordinate measurement and point diffraction interference, which is applied in the field of point-diffraction interference three-coordinate measurement device probe end face leveling, can solve problems such as difficult leveling and affecting measurement accuracy, meet the solution requirements, and achieve fast three-dimensional coordinate reconstruction results and precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

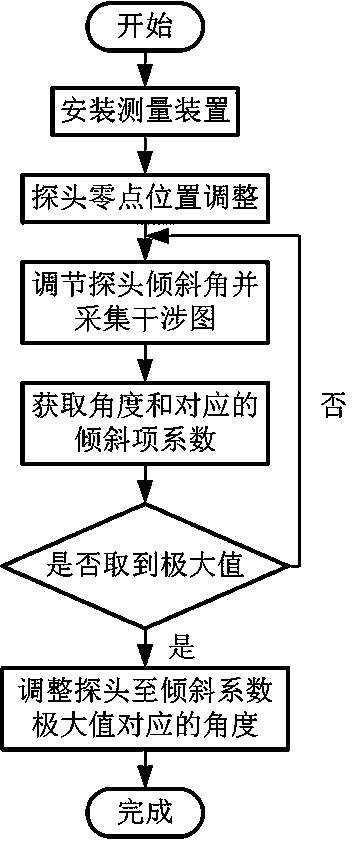

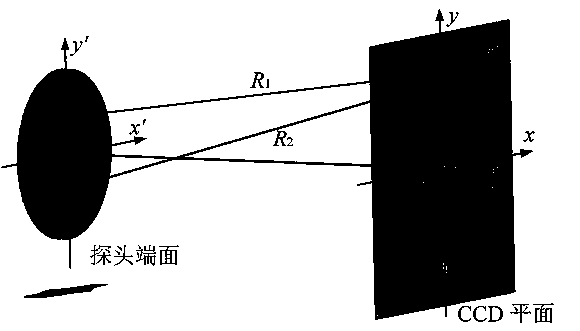

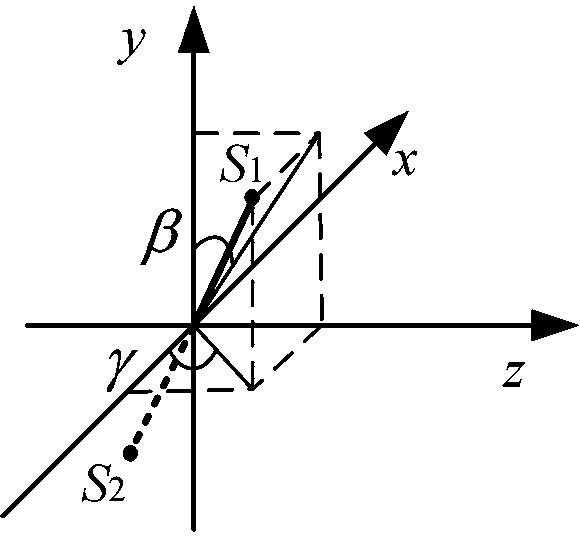

[0029] like Figure 1-7 A method for leveling the probe end face of a point-diffraction interference three-coordinate measuring device is shown. Including a three-coordinate measuring device, a CCD detector, a two-dimensional tilt adjustment frame, and a three-dimensional translation guide rail. The probe of the three-coordinate measuring device is composed of the combined installation of two optical fiber exit faces. The probe is installed on the two-dimensional tilt adjustment frame, and the probe and the two-dimensional adjustment frame are integrally installed on the three-dimensional translation guide rail. The outgoing ends of the two optical fibers are the end faces of the probe. The end face of the probe faces the CCD detector. The CCD detector does not have an imaging lens. Adopting the method of the present invention is that the measurement probe in the point diffraction interference three-dimensional coordinate measurement of 45 ° is carried out the adjustment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com