A LED constant current drive circuit with high pf and no flicker

A constant current drive, no flicker technology, applied in the direction of electric light source, electrical components, electroluminescent light source, etc., can solve the problems of LED load current ripple, large ripple, PF difference, etc., to reduce the ripple The effect of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

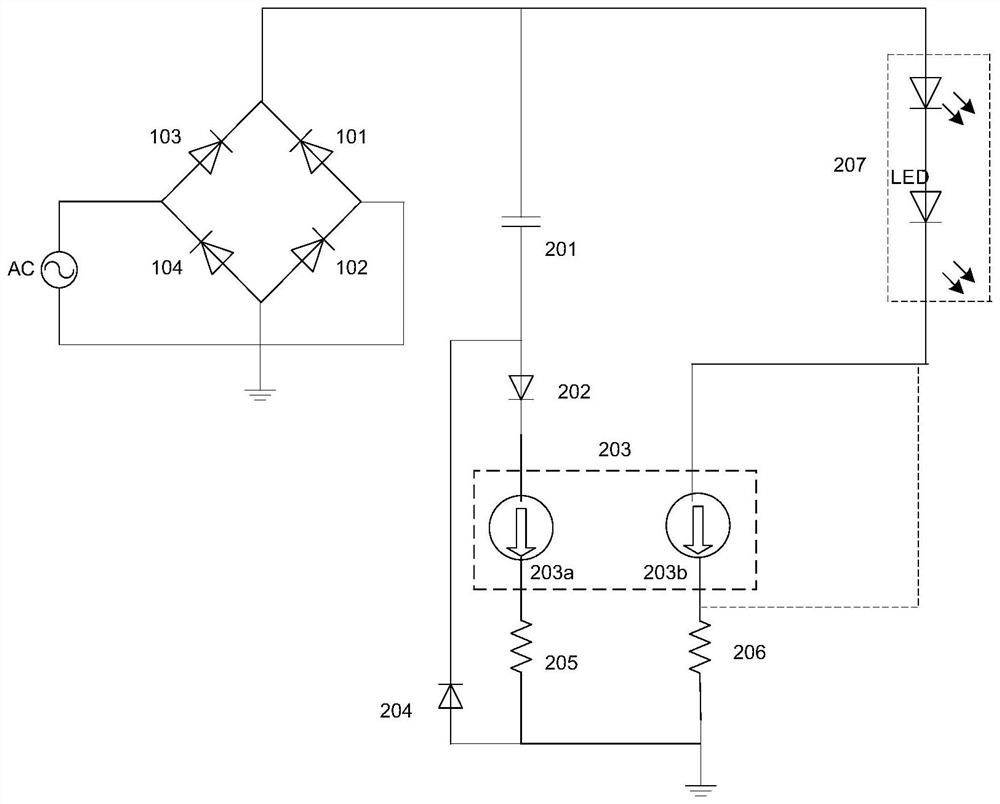

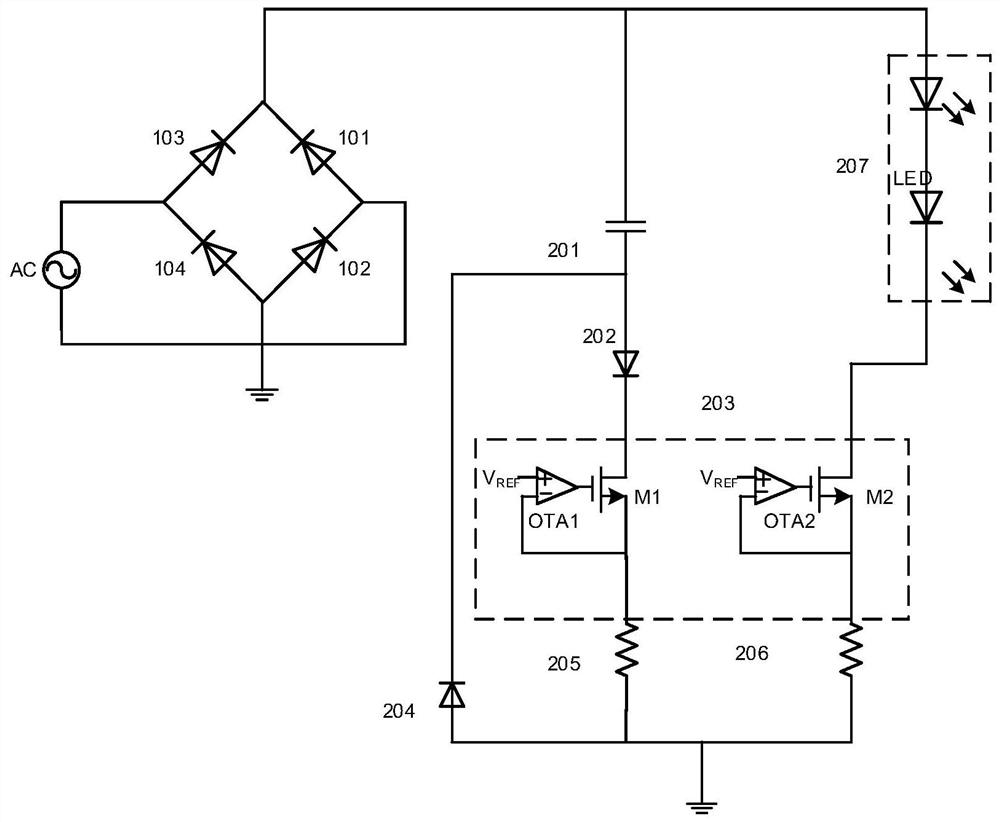

[0040] image 3 It is the LED constant current drive circuit diagram with high PF and no flicker of the first embodiment.

[0041] Such as image 3 As shown, in this embodiment, the LED constant current drive circuit with high PF and no flickering includes: including: input rectifier bridge, LED light string 207, energy storage capacitor 201, constant current control unit 203, first diode 202 , the first feedback resistor 205 , the second feedback resistor 206 and the second diode 204 .

[0042] The constant current control unit 203 includes: a first constant current source and a second constant current source. In this embodiment, the first constant current source includes: a MOS transistor M1 and an operational amplifier OTA1. The gate of the MOS transistor M1 serves as a control terminal of the first constant current source, and the source of the MOS transistor M1 serves as the other control terminal of the first constant current source. The second constant current source ...

Embodiment 2

[0051] Figure 4 It is the LED constant current drive circuit diagram with high PF and no flicker of the second embodiment.

[0052] Such as Figure 4 As shown, in this embodiment, the LED constant current drive circuit with high PF and no flickering includes: including: input rectifier bridge, LED light string 207, energy storage capacitor 201, constant current control unit 203, first diode 202 , the first feedback resistor 205, the second feedback resistor 206, the second diode 204, the inductor 209A and the third diode 208B.

[0053] The constant current control unit 203 includes: a first constant current source and a second constant current source. In this embodiment, the first constant current source includes: a MOS transistor M1 and an operational amplifier OTA1. The drain of the MOS transistor M1 serves as a control terminal of the first constant current source, and the source of the MOS transistor M1 serves as the other control terminal of the first constant current...

Embodiment 3

[0062] Figure 5 It is the LED constant current drive circuit diagram with high PF and no flicker of the third embodiment.

[0063] Such as Figure 5 As shown, in this embodiment, the LED constant current drive circuit with high PF and no flickering includes: including: input rectifier bridge, LED light string 207, energy storage capacitor 201, constant current control unit 203, first diode 202 , the first feedback resistor 205, the second feedback resistor 206, the second diode 204, the transformer 209B, the third diode 208B and the first capacitor 210B.

[0064] The constant current control unit 203 includes: a first constant current source and a second constant current source. In this embodiment, the first constant current source includes: a MOS transistor M1 and an operational amplifier OTA1. The drain of the MOS transistor M1 serves as a control terminal of the first constant current source, and the source of the MOS transistor M1 serves as the other control terminal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com