Detection system for surface damage data of underwater equipment

A technology of surface damage and data detection, applied in the direction of material magnetic variables, etc., can solve problems such as unclear equipment testing standards and evaluation standards, unclear equipment testing range, and unclear reflection of underwater oil equipment testing technology, so as to ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

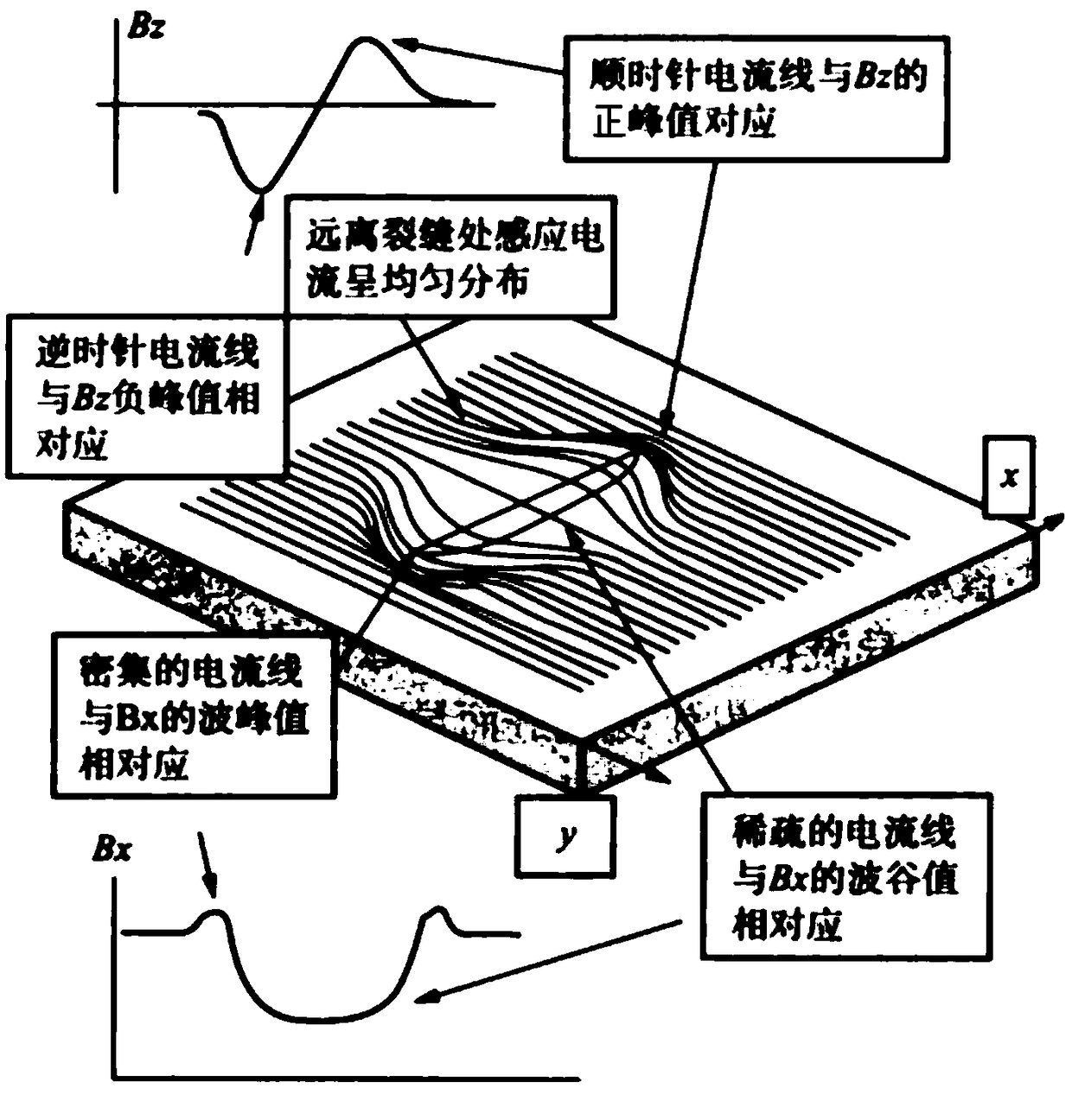

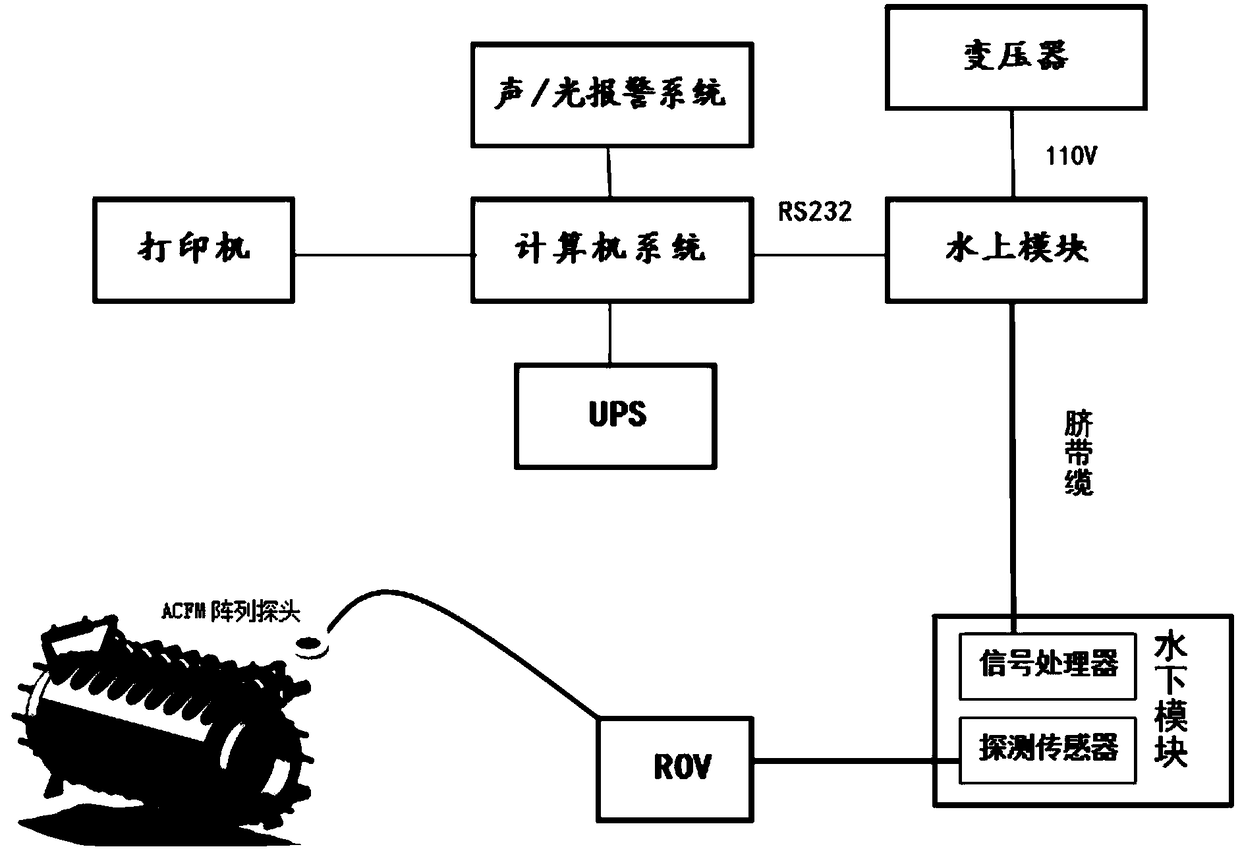

[0025] The surface damage data detection of underwater equipment will use ACFM AC electromagnetic field technology. ACFM is a new non-destructive testing technology developed from the AC potential drop and eddy current testing methods. Its principle is to uniformly induce alternating current in the equipment. Detect changes in the magnetic field on the surface of the equipment to achieve defect assessment. This technology has the following advantages, non-contact detection, qualitative and quantitative detection is completed at one time, no calibration is required, it can penetrate metal and non-metal coatings, and can accurately detect the length and width of damage, no need to clean the surface covering during detection, high Stability, high resolution. The ACFM detection method has been certified by DNV, ABS, BV, etc., confirming that the use of ACFM in the detection of offshore oil equipment is an important method for underwater equipment detection.

[0026] During ACFM d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap