Pipe joint structure

A technology of pipe joint and connecting seat, which is applied in the direction of pipe/pipe joint/pipe fitting, sealing surface connection, passing element, etc., which can solve the problems of weak positioning force and the inability of the pipe joint 80 to be completely sealed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

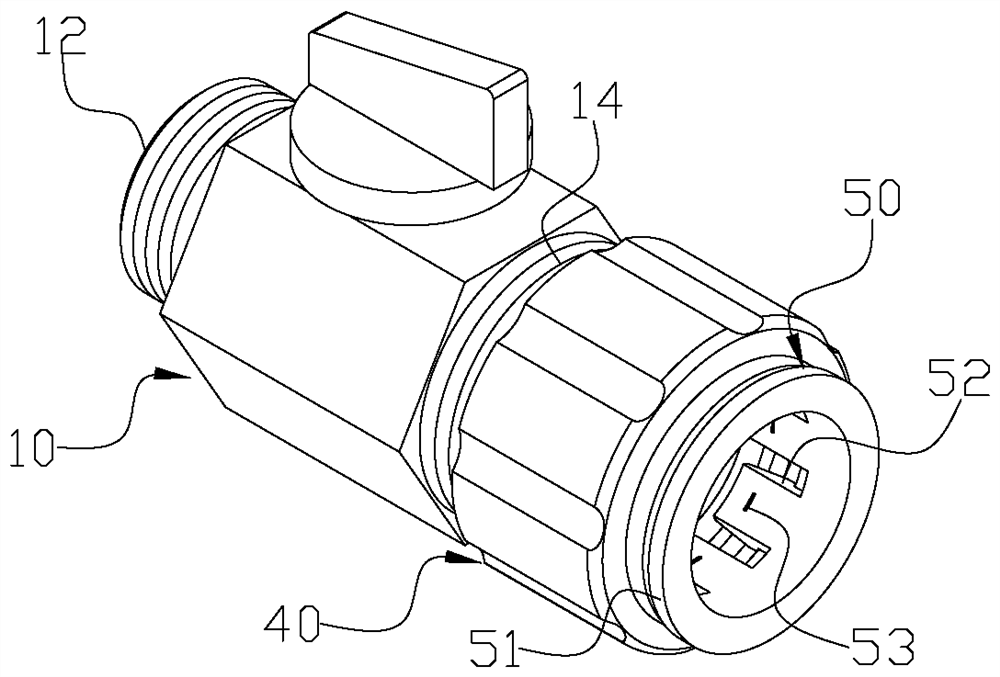

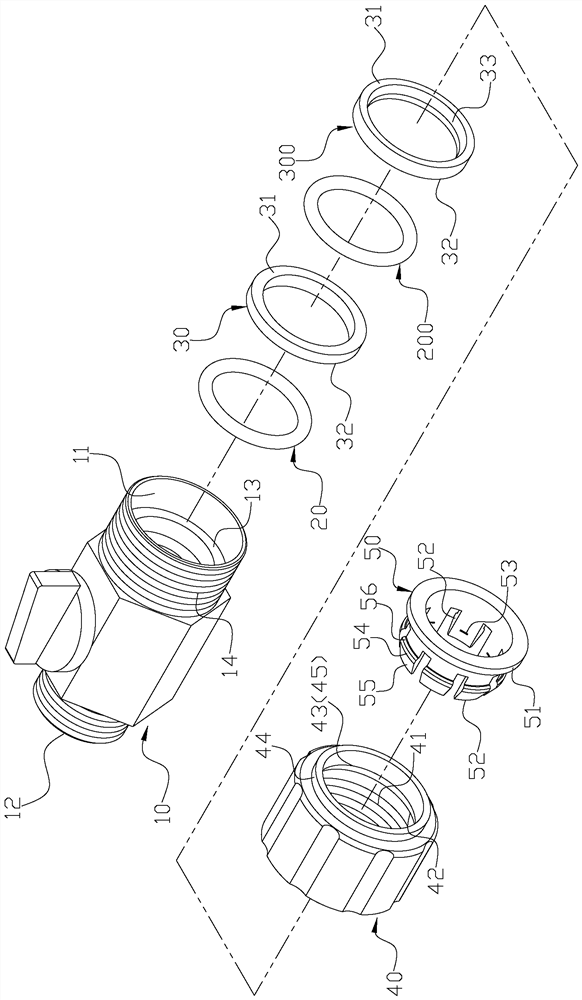

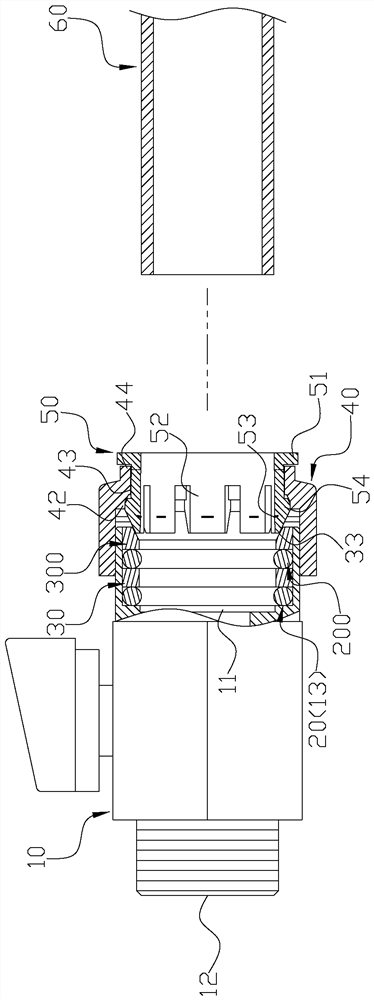

[0036] First, as Figure 1 to Figure 4 As shown, it includes: a joint body 10, a first O-ring seal 20, a second O-ring seal 200, a first auxiliary positioning ring 30, a second auxiliary positioning ring 300, and a locking screw 40 and a connecting seat 50, wherein the connector body 10 has a first opening 11 and a second opening 12 which are connected and conducted. The first opening 11 is provided with a ring protrusion 13. The outer edge of the opening 11 is provided with a first thread segment 14 , the first auxiliary positioning ring 30 and the second auxiliary positioning ring 300 each have a first end 31 , a second end 32 , an inner ring portion and an outer ring portion , the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com