Hot working process online measurement system and transparent material dynamic deformation measurement method

A measurement system and transparent material technology, which is applied in the field of glass processing, can solve the problems of only observation, no measurement system glass, and observation angle restrictions, and achieve the effect of overcoming visual inspection of the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

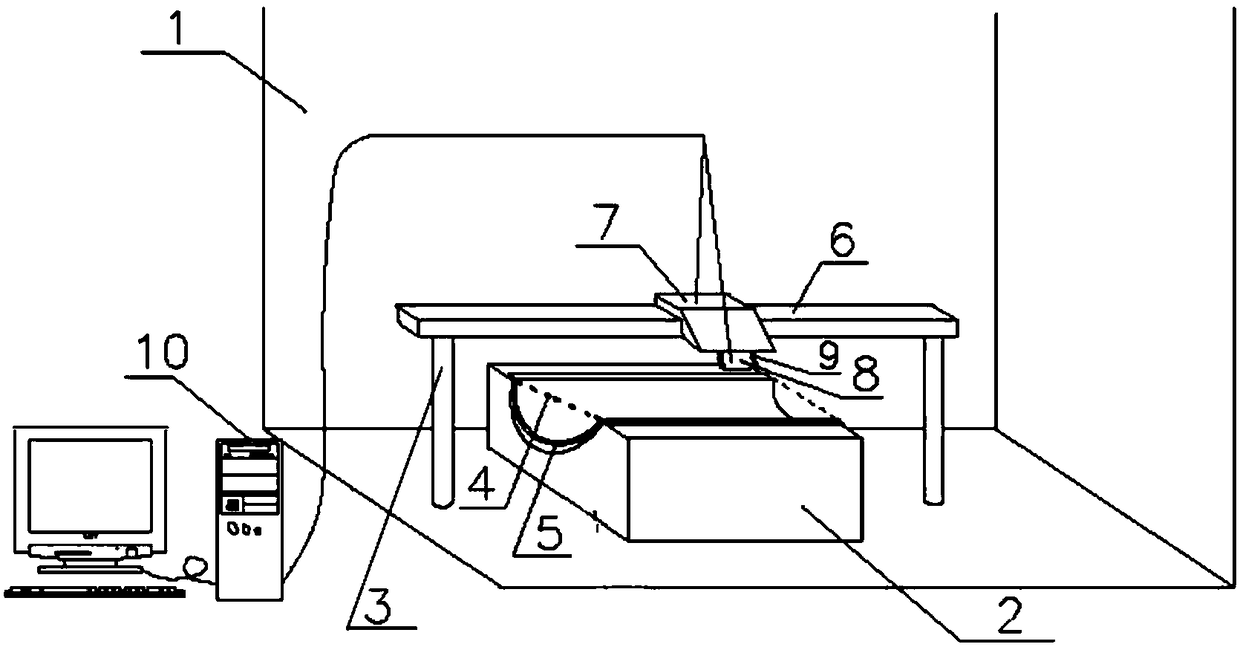

[0087] Draw a grid S less than 20mm on the surface of the plexiglass of the material to be processed 1 and mark points A, B, C..., then fix the thermal processing mold and the plexiglass to be processed, and put them into an oven to shape the plexiglass at 115°C; measure the temperature of the plexiglass during the thermal processing in real time out of shape.

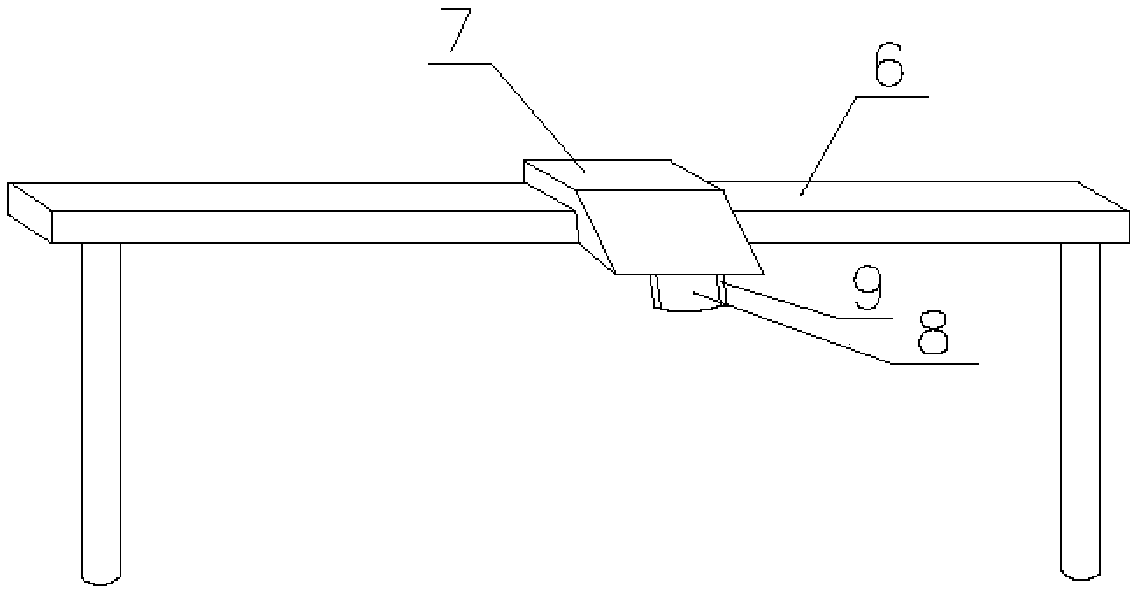

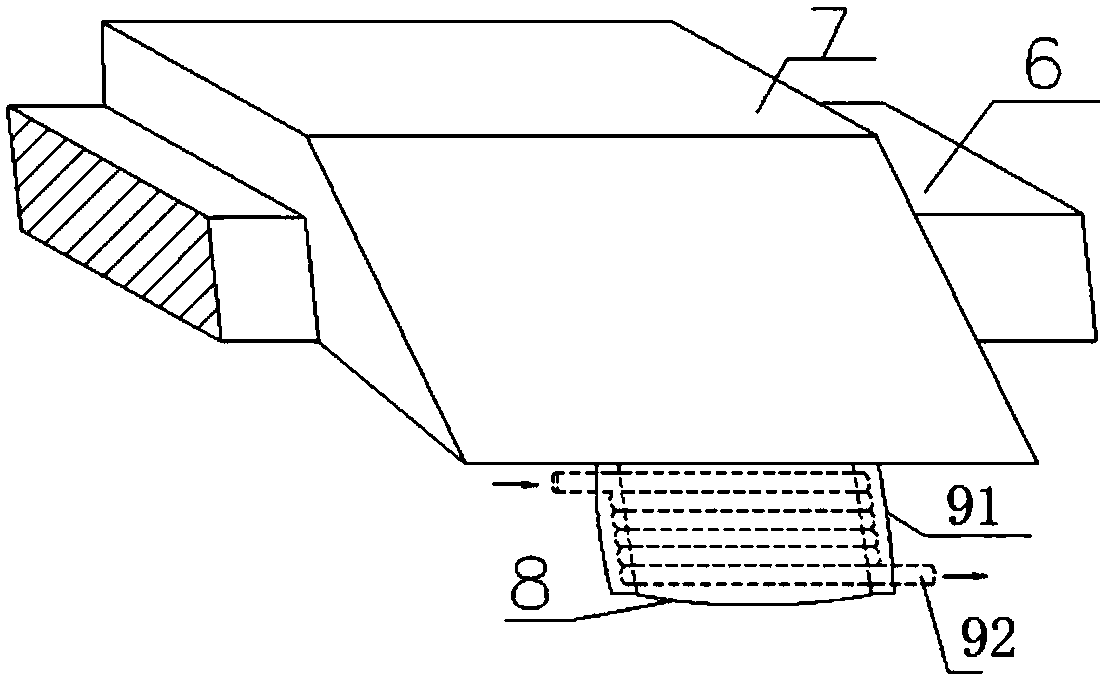

[0088] A gantry bracket is arranged in the oven, and a slide rail and a slider are arranged on the straight beam of the bracket; the slider can move along the slide rail; a detection head is installed at the lower end of the slider; the surrounding of the detection head is Wrap the flexible silicone tubing with built-in cold water circulation; then, wrap the flexible silicone tubing with insulating cotton. Adjusting the positions of the bracket and the thermal processing mold enables the detection head to clearly detect the states of each point on the plexiglass during the whole process of thermal processing.

[0089...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com