Sealed mechanical combination lock

A technology for sealing holes and locks, which is applied in combination locks, building locks, and numbered locks. It can solve the problems of unstable performance, inability to change passwords, and destructive opening of locks, and achieve simple and easy operation and high safety factor. , password adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

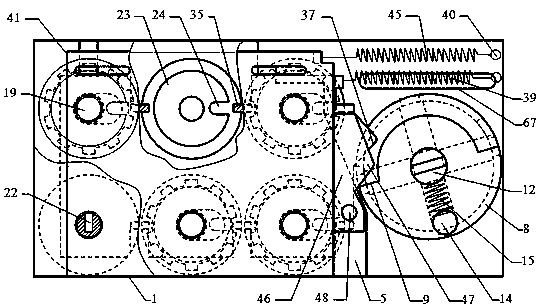

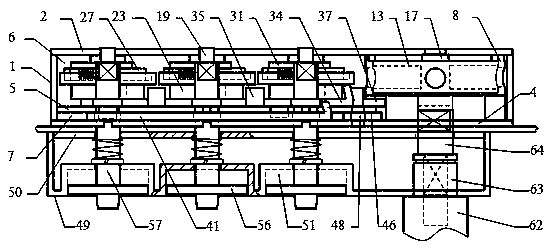

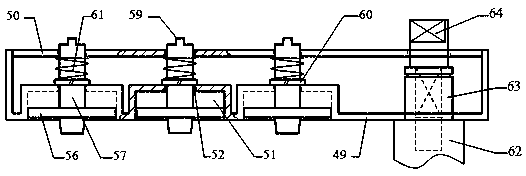

[0063] Such as figure 1 , 2 As shown, the hole-sealing type mechanical combination lock includes a lock body 1, a lock outer panel 49 and a handle 62, and the inner side of the lock outer panel 49 is assembled with a back plate 50, as shown in FIG. image 3 As shown, the back plate 50 is provided with 1 large through hole and 6 small through holes, and the outer side of the lockset outer panel 49 is provided with 6 inwardly recessed cylindrical knob shallow holes 51 and 1 handle mounting hole, each An alignment star (not shown in the figure) is provided directly above the shallow holes of the knobs, and a central through hole 52 is provided in the center of each shallow knob hole 51, which is coaxial with the six small through holes of the back plate 50 respectively. The handle mounting hole is coaxial with the large through hole on the back plate 50 . Six mutually independent knob disks 56, knob shafts 57 and knob springs 61 are movably assembled in the lockset outer panel...

Embodiment approach 2

[0086] The difference from Embodiment 1 lies in that the shape of the swing rod is different, and the connection mode when the swing rod drives the lock bolt to move is different.

[0087] Such as Figure 38 As shown, there is no oblong hole at the end of the fork A72. Such as Figure 40 ,41 , 42, the lock body 1 is provided with a lock bolt driving plate 69, and is located at the upper part of the inner side of the turntable cavity 6, and its right end is provided with a push-pull opening 70, and is movably assembled with the end of the fork A72, and the push-pull opening 70 The left side is provided with slide pin 71, and this slide pin 71 is perpendicular to lockbolt driving plate 69, and both are fixedly assembled by riveting or welding, and slide pin 71 stretches out to the outside of lock body 1 after being movably inserted into unlocking slideway 67, slide pin 71. A spacer is assembled on the protruding part, and its end is provided with an annular groove to assemble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com