Field hardness detection result comparison test method

A comparative test and hardness technology, applied in the direction of testing material hardness, measuring devices, strength characteristics, etc., can solve the problems of high site environmental requirements, affecting the production cycle, and not meeting the requirements of hardness testing in the efficient production period, so as to avoid technical disputes, The effect of reducing the cost of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0029] Example.

[0030] The on-site hardness detection effect comparison test method in the present embodiment comprises the following steps:

[0031] Step S1: Selection of test environment.

[0032] In this embodiment, the test environment is at a temperature of 25° C., and there is no vibration, no strong magnetic field, and no corrosive medium around.

[0033] Step S2: Selection of test equipment.

[0034] In this embodiment, the test equipment includes a portable Leeb hardness tester model HT-2000A, a portable Brock hardness tester model PHBR-100 and a laboratory tester model HBE-3000A. Electronic Brinell hardness tester.

[0035] Step S3: Selection of test subjects.

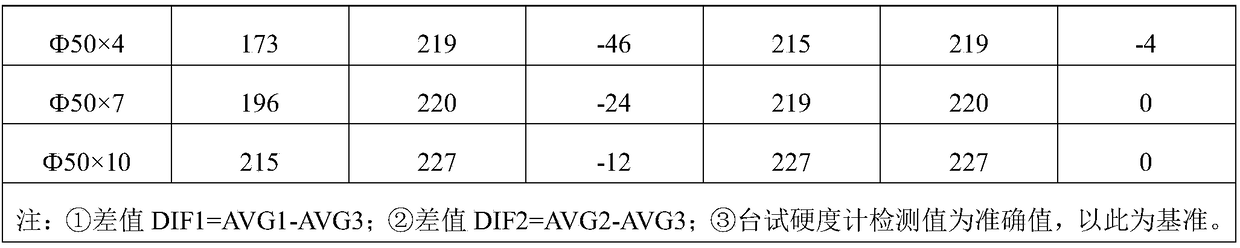

[0036] In this embodiment, the test objects are T91 tubes commonly used in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com